Maple syrup facts for kids

Maple syrup is a sweet, thick syrup made from the sap of maple trees. It's mostly made of a sugar called sucrose. People often pour it over waffles and pancakes. You can also use maple syrup to bake treats like pies, make candy, or just add sweetness to food. It's even sometimes used in lemonade!

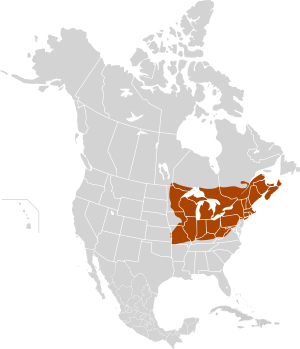

People in eastern North America first used maple syrup. Later, European settlers learned how to make it too. Syrups are usually bottled when they are hot.

The Canadian province of Quebec makes most of the world's maple syrup. It produces about three-quarters of all maple syrup globally.

In cold places, maple trees store starch in their trunks and roots during winter. When spring comes, this starch turns into sugar. This sugary sap then rises up the tree.

Contents

Which Maple Trees Make Syrup?

Three main types of maple trees are used to make maple syrup. These are the sugar maple (Acer saccharum), the black maple (A. nigrum), and the red maple (A. rubrum). These trees are chosen because their sap has a lot of sugar, usually between two and five percent.

Some scientists think the black maple is a type of sugar maple. The red maple has a shorter syrup-making season. This is because its buds open earlier than the sugar and black maples. This change can affect the taste of its sap.

A Sweet History: How Maple Syrup Began

Who First Made Maple Syrup?

Indigenous peoples in northeastern North America were the first to make maple syrup and sugar. They were making it long before Europeans arrived. We don't know exactly how it started, but there are many old stories. One popular story says maple sap was used instead of water to cook venison for a chief. Other stories give credit to heroes like Nanabozho or Glooscap.

Native American tribes had special traditions around making sugar. They celebrated the "Sugar Moon," which was the first full moon of spring, with a Maple Dance. Many of their dishes used maple sugar or syrup instead of salt.

The Algonquian people knew that maple sap gave them energy and food. When spring thaws began, they used stone tools to cut V-shapes into tree trunks. They put reeds or bark pieces into the cuts to guide the sap into buckets. These buckets were often made from birch bark. To make the sap thicker, they would drop hot cooking stones into the buckets. Or, they would leave the buckets out overnight in the cold. The ice that formed on top would be removed, leaving sweeter sap behind.

How Did Europeans Learn to Make It?

When Europeans first came to northeastern North America, Indigenous peoples taught them how to tap maple trees. They showed them how to collect the sap during the spring thaw. A French explorer named André Thevet wrote about Jacques Cartier drinking maple sap during his trips to Canada. By the late 1600s, European settlers and fur traders were also collecting maple sap.

Europeans used a different method to tap trees. Instead of cuts, they drilled holes in the trunks with augers. In the 1600s and 1700s, maple sap was mainly used as a source of sugar. This was because cane sugar had to be brought all the way from the West Indies.

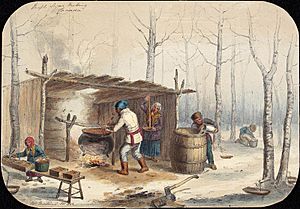

Maple sugaring parties would start when the spring thaw began. This happened in areas with many maple trees. Syrup makers drilled holes in the trees, sometimes more than one per large tree. They put wooden spouts into the holes and hung wooden buckets to catch the sap. The buckets were often made by hollowing out logs.

The sap would fill the buckets. Then, it was moved to bigger containers like barrels or large pots. These were often pulled by draft animals on sleds or wagons. The empty buckets were put back on the trees. This process continued as long as the sap tasted sweet. The weather during the thaw was, and still is, very important. If it gets too warm, the sap's taste changes, and it's no longer good for syrup.

Boiling the sap was a very long process. The collected sap was taken back to a camp. There, it was poured into large metal pots and boiled over a fire. This fire was either out in the open or inside a special building called a "sugar shack."

Maple Syrup Making Since 1850

Around the time of the American Civil War (1861-1865), syrup makers started using large, flat metal pans. These pans were better for boiling than the old, round iron kettles. They had a bigger surface area, which helped the water evaporate faster. Around this time, cane sugar became more popular than maple sugar in the US. So, maple syrup makers started focusing on selling syrup instead of sugar.

The first machine to heat and thicken sap was invented in 1858. In 1872, a new evaporator was made with two pans and a metal firebox. This greatly reduced the boiling time. Around 1900, producers started bending the bottom of the pans into flues. This increased the heated area even more and made boiling faster. Some also added a separate "finishing pan" for the final boiling step.

Buckets for collecting sap started to be replaced with plastic bags. These bags let people see how much sap was collected from a distance. Syrup makers also began using tractors to pull large tanks of sap from the trees to the boiling house. Some even used motor-powered taps and metal tubes to move sap directly from the tree to a central container.

Today, producers use different ways to heat the sap. They use wood, oil, natural gas, propane, or steam. Modern filtering methods were also developed to keep the syrup clean.

Many big changes happened in the 1970s. Plastic tubing systems, which had been tested for a long time, became much better. Now, sap could flow directly from the tree to the boiling house. Vacuum pumps were added to these tubing systems. Preheaters were also developed to reuse heat from the steam. Producers also started using reverse-osmosis machines. These machines remove some water from the sap before it's boiled, making the process much faster.

Since then, tubing and vacuum pumps have improved even more. New filtering methods, better preheaters, and improved storage containers have also been developed. Scientists are still working on ways to control pests and manage maple forests better. In 2009, researchers at the University of Vermont created a new type of tap. This tap stops sap from flowing back into the tree. This helps prevent bacteria from getting into the sap and stops the tree from trying to heal the tap hole. Experiments also show that it might be possible to use young maple trees in a plantation instead of older ones. This could greatly increase how much syrup can be made from each acre of land.

How Maple Syrup is Made

The basic way of boiling sap in open pans is still similar to how it was done long ago. First, the sap must be collected. Then, it's boiled down to make pure syrup without any chemicals. To make one bottle of syrup, you need to boil down about 20 to 50 bottles of sap. The exact amount depends on how much sugar is in the sap. The sap is usually boiled until it reaches a temperature about 4.1°C (7.4°F) higher than the boiling point of water. Since the boiling point of water changes with air pressure, producers check it often.

Boiling the syrup is carefully controlled to make sure it has the right amount of sugar. If syrup is boiled too long, it will turn into crystals. If it's not boiled enough, it will be watery and spoil quickly. Finished syrup has a density of 66° on the Brix scale. This scale measures sugar solutions. After boiling, the syrup is filtered to remove "sugar sand." These are tiny crystals made of sugar and calcium. They aren't harmful, but they make the syrup feel gritty if not removed.

Many large syrup makers also use a process called reverse osmosis. This method is more energy-efficient. It helps remove water from the sap before it's boiled.

The more sugar in the sap, the less sap you need to make the same amount of syrup. For example, if sap has 1.5% sugar, you need 57 units of sap for 1 unit of syrup. But if sap has 3.5% sugar, you only need 25 units of sap for 1 unit of syrup. The sugar content in sap can change a lot, even in the same tree.

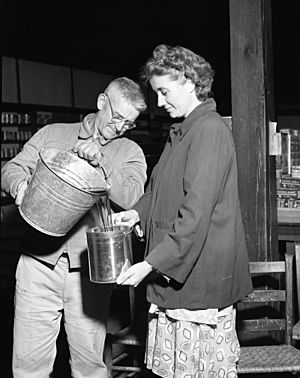

The filtered syrup is then graded and packaged while it's still hot, usually at 82°C (180°F) or hotter. The containers are turned upside down after being sealed. This helps sterilize the cap with the hot syrup. Syrup can be packaged in metal, glass, or plastic containers. Syrup can also be boiled longer to make other maple products. These include maple sugar, maple butter or cream, and maple candy or taffy.

What Can Affect Syrup Taste?

Sometimes, maple syrup can have strange tastes. This can happen if there are things like disinfectants in the boiling equipment. Tiny living things called microorganisms can also cause problems. Fermentation products, metallic tastes from cans, or "buddy sap" can also affect the flavor. "Buddy sap" happens late in the season when tree budding begins. Sometimes, these off-flavors can be removed during processing.

Where Maple Syrup Comes From

Most maple syrup is made in northeastern North America. However, if the weather is right, it can be made wherever suitable maple trees grow.

A maple syrup farm is called a "sugarbush" or "sugarwood." Sap is often boiled in a "sugar house" (also known as a "sugar shack" or cabane à sucre). This building has openings at the top to let the steam out from the boiling sap.

Maple trees are usually tapped when they are 30 to 40 years old. Each tree can have one to three taps, depending on how wide its trunk is. An average maple tree makes about 35 to 50 liters (9 to 13 US gallons) of sap per season. It can produce up to 12 liters (3 US gallons) per day. This is about seven percent of its total sap. The syrup season lasts for four to eight weeks, depending on the weather. During the day, starch stored in the roots rises through the trunk as sugary sap, ready to be tapped. Sap is not usually tapped at night because cold temperatures stop the sap flow. However, taps are usually left in place overnight. Some producers also tap in the autumn, but this is less common than spring tapping. Maple trees can continue to be tapped for sap for over 100 years!

Images for kids

See also

In Spanish: Jarabe de arce para niños

In Spanish: Jarabe de arce para niños

| Stephanie Wilson |

| Charles Bolden |

| Ronald McNair |

| Frederick D. Gregory |