Vacuum pump facts for kids

A vacuum pump is a special device that removes gas from a sealed space. This creates a partial vacuum, which is an area with very little air or gas. The first vacuum pump was made in 1650 by Otto von Guericke. Before that, people used suction pumps, which have been around for a very long time.

Contents

History of Vacuum Pumps

Early Suction Pumps

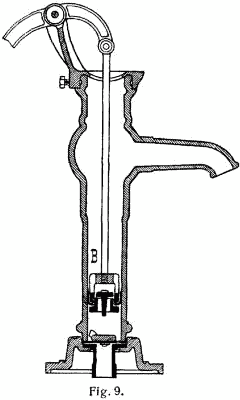

Long ago, people used suction pumps. These pumps could pull water up. In the ancient city of Pompeii, people found double-action suction pumps. Later, in the 1200s, an Arabic engineer named Al-Jazari described these pumps. He said they were used in machines that lifted water. He also mentioned a suction pump used with siphons to move "Greek fire." Suction pumps then appeared in Europe in the 1400s.

By the 1600s, water pumps were much better. They could create a measurable vacuum, but people didn't understand it right away. They knew that suction pumps could only lift water about 34 feet (about 10 meters). This limit was a problem for farms and mines. So, the Duke of Tuscany asked Galileo Galilei to study it. Galileo thought the water column broke under its own weight.

Other scientists then looked into the problem. Gasparo Berti built the first water barometer in 1639. It made a vacuum above the water, but he couldn't explain it. Then, in 1643, Galileo's student Evangelista Torricelli made a big discovery. He built the first mercury barometer. Torricelli showed that the empty space at the top was indeed a vacuum. He explained that the air pressure outside limited how high the water could be pulled.

In 1650, Otto von Guericke invented the very first true vacuum pump. Four years later, he did his famous Magdeburg hemispheres experiment. He showed that even teams of horses could not pull apart two metal hemispheres when the air was removed from inside them. Robert Boyle later improved Guericke's pump. He used it to study how vacuum works. Robert Hooke also helped Boyle build a better air pump.

By 1709, Francis Hauksbee made an even better pump. It had two cylinders and could create a very good vacuum. This design was popular for a long time, even into the 1800s.

19th Century Vacuum Advances

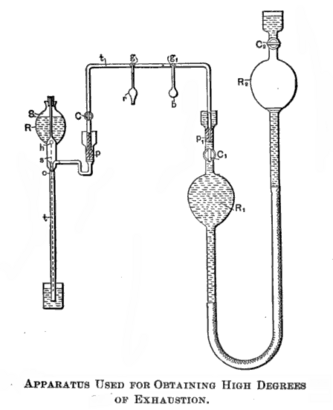

In 1855, Heinrich Geissler invented the mercury displacement pump. This pump created a much stronger vacuum. At this level of vacuum, scientists could see new electrical effects. This led to more interest in vacuum technology. It also helped in making the first vacuum tubes. The Sprengel pump was another important vacuum pump from this time.

20th Century Vacuum Pumps

The early 1900s brought many new types of vacuum pumps. These included the molecular drag pump, the diffusion pump, and the turbomolecular pump. These inventions helped create even stronger vacuums for new technologies.

Types of Vacuum Pumps

Vacuum pumps work in three main ways:

- Positive displacement: These pumps trap gas and move it out.

- Momentum transfer: These pumps use fast-moving parts or fluids to push gas molecules away.

- Entrapment: These pumps capture gas molecules, often by freezing them or reacting with them.

Positive displacement pumps are best for creating a low vacuum. For a very strong vacuum, momentum transfer pumps are often used. They usually work with one or two positive displacement pumps. The positive displacement pump first creates a rough vacuum. This is because momentum transfer pumps cannot start working at normal air pressure. The positive displacement pump also helps by removing the gas that the momentum transfer pump pushes out.

Entrapment pumps can create extremely strong vacuums. However, they need to be "cleaned" or reset regularly. This means they are mostly used for very high vacuum levels. Pumps also differ in how they are made, what materials they use, and how well they handle dust or chemicals.

Positive Displacement Pumps

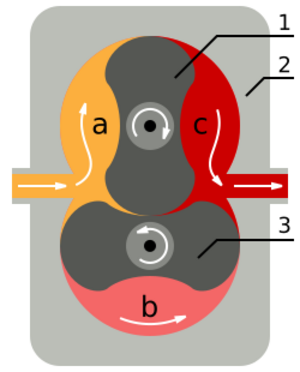

A partial vacuum can be made by making a container bigger. To keep removing gas, a part of the pump repeatedly closes off, lets gas in, seals, and then pushes the gas out. This is how a positive displacement pump works. Think of a manual water pump. Inside, a part expands a small sealed space. This lowers the pressure inside. Because the pressure outside is higher, gas (or water) from the chamber rushes into this small space. Then, the pump seals off this space, opens it to the outside air, and squeezes the gas out.

More advanced pumps are used in factories, but they use the same basic idea. They remove a set amount of gas with each cycle. Here are some common types:

- Rotary vane pump: This is the most common type.

- Diaphragm pump: This pump does not use oil, so it keeps things clean.

- Liquid ring: This type is good at handling dust.

- Piston pump: This pump creates a vacuum that changes a bit.

- Scroll pump: This is a very fast dry pump.

- Roots blower: Also called a booster pump, it moves a lot of gas quickly.

These pumps can reach different vacuum levels. A scroll pump might get down to 10 Pa (Pascals). A rotary vane oil pump can easily reach 0.1 Pa.

Momentum Transfer Pumps

A momentum transfer pump (or kinetic pump) works by speeding up gas molecules. It pushes them from the vacuum side to the exhaust side. These pumps work best at very low pressures, below about 0.1 kPa. At these low pressures, gas molecules hit the pump's walls more often than they hit each other. This makes momentum transfer pumping very effective.

These pumps can move gas much faster than mechanical pumps. However, they don't have a perfect seal. This means that if the pressure at the exhaust side is too high, gas can flow back into the vacuum. This is called "stall."

The two main types are the diffusion pump and the turbomolecular pump. Both push gas molecules out by giving them a "kick." Diffusion pumps use fast jets of oil or mercury vapor. Turbomolecular pumps use very fast spinning blades, like tiny fans. Both types need a "backing pump" (a mechanical pump) to create a lower vacuum for them to work. This is because they cannot pump directly from normal air pressure.

Entrapment Pumps

An entrapment pump traps gases. A cryopump uses very cold temperatures to turn gases into a solid or make them stick to a surface. A chemical pump reacts with gases to form a solid. An ion pump uses strong electric fields to turn gases into ions and push them into a solid material. Other types include the sorption pump and the titanium sublimation pump.

How Pumps Perform

Pumping speed tells you how much gas volume a pump can move in a certain amount of time. For some pumps, this speed can be different for different gases.

Throughput is the pumping speed multiplied by the gas pressure at the pump's inlet. It tells you how many gas molecules are being pumped out per unit of time. If there's a leak in the system, the leak's throughput can be compared to the pump's throughput.

As the pressure in a chamber drops, the same volume of gas contains fewer and fewer molecules. So, even if the pumping speed stays the same, the actual number of molecules being removed drops. Meanwhile, leaks and gases coming out of materials (outgassing) can keep adding a steady amount of gas to the system.

Vacuum Techniques

Vacuum pumps are often used together in different ways. Sometimes, more than one pump is used at once. To create a partial vacuum, a positive displacement pump is used first. It removes most of the air from a chamber, from normal air pressure down to a low vacuum. To get an even stronger vacuum, other pumps are then used in a series. For example, an oil-sealed rotary vane pump might back up a diffusion pump. Or a dry scroll pump might back up a turbomolecular pump. The choice depends on how strong a vacuum is needed.

Getting a very strong vacuum is tricky. All materials inside the vacuum chamber must be chosen carefully. They should not release too much gas (outgassing) or boil away. For example, oils, greases, and rubber seals can release gases into the vacuum. This would stop the pump from reaching the desired vacuum level. Often, the surfaces inside the vacuum chamber are heated to make any trapped gases come out. These gases are then pumped away.

High-vacuum systems usually use metal chambers with metal seals, not rubber. The system must be very clean to reduce outgassing. Many materials that work fine in low vacuums, like some glues, will release too much gas in higher vacuums. With careful design, vacuums of 1 mPa (millipascal) are easy to reach. With even more care, 1 μPa (micropascal) is possible.

For ultra-high vacuum, special equipment and strict steps are needed. These systems are often made of stainless steel with metal seals. The system is usually baked, often while under vacuum, to make all the trapped gases come out. Once these gases are removed, the system is cooled down. This helps keep the vacuum strong during use. Some systems are even cooled with liquid nitrogen to stop outgassing and help trap gases.

In ultra-high vacuum systems, even tiny leaks or gas sources matter. Water absorbed by metals like aluminium can be a problem. Even the tiny holes in hard metals like stainless steel must be considered. Some oils and greases will boil away in extreme vacuums.

The size of gas molecules also matters. Smaller molecules like helium or hydrogen can leak in more easily. They are also harder for some molecular pumps to remove. So, a system might remove nitrogen well, but still have a lot of hydrogen and helium left.

Uses of Vacuum Pumps

Vacuum pumps are used in many different areas, including:

- Removing air from liquids (vacuum deaerator).

- Making plastic parts using molds.

- Producing most types of light bulbs, vacuum tubes, and old TV screens (CRTs).

- Making semiconductors for computers and phones.

- In electron microscopes.

- Medical procedures that need suction.

- Enriching uranium.

- Medical treatments like radiotherapy.

- Analyzing materials in labs (mass spectrometers).

- Applying coatings to glass, metal, and plastics for decoration or protection.

- Filling porous products like wood with liquids.

- Servicing air conditioning systems.

- In sewage systems.

- Freeze drying food.

- Research into fusion energy.

In cars, vacuum pumps or the engine itself can create a vacuum. This vacuum helps power things like:

- The vacuum servo booster for the hydraulic brakes.

- Motors that move air vents in the car's heating system.

- The cruise control system.

- Door locks or trunk releases.

In aircraft, the vacuum source often powers gyroscopes in the flight instruments. This is important because if the plane loses electrical power, some instruments will still work using the vacuum.

Vacuum pumps can be powered by electricity, air pressure, or other methods.

Hazards

Some older vacuum pump oils, made before about 1980, contain dangerous chemicals called polychlorinated biphenyls (PCBs). These chemicals are very toxic and can cause cancer. They also stay in the environment for a long time.

See also

- An Experiment on a Bird in the Air Pump

- Vacuum sewerage