Risdon Zinc Works facts for kids

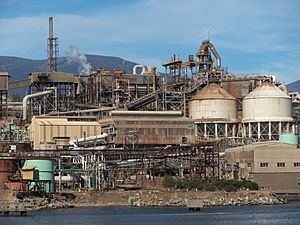

The Risdon Zinc Works (also known as Nyrstar Hobart) is a very large factory that processes zinc. It is located in Lutana, a suburb of Hobart, Tasmania, Australia. This factory is one of the biggest zinc producers in the world. It makes over 280,000 tonnes of high-quality zinc every year.

This zinc is used to make many things, like die-cast parts and materials for galvanising. These products are sent all over the world. They are used in buildings, transport, electronics, and many everyday items.

The factory makes zinc using a special method called Roast, Leach, Electrowinning (RLE). This process also creates other materials like cadmium, gypsum, and sulphuric acid. Since 2007, the factory has been owned by a global company called Nyrstar. Nyrstar Hobart works closely with another Nyrstar factory in Port Pirie, South Australia. In 2013, this factory was Tasmania's largest exporter, sending out 25% of the state's total exports.

Contents

History of the Zinc Works

The story of the zinc works began in 1908. A man named James Hyndes Gillies came to Hobart with a big idea. He wanted to build a zinc factory and a hydroelectric power plant. The power plant would make the electricity needed for the zinc process.

Gillies bought land near Hobart in 1909. He planned to build a zinc plant and other factories that used a lot of energy. He started a company called the Hydro-Electric Power and Metallurgical Company. The Tasmanian Government gave him permission to build a dam and power plant. However, Gillies could not find enough money. So, the Tasmanian Government took over the project in 1914. Gillies only managed to build a carbide factory.

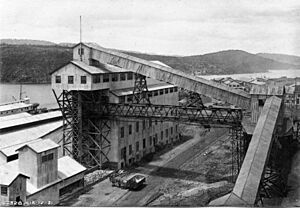

Building the Zinc Factory

Before the First World War, Britain got most of its zinc from Germany and Belgium. When the war started, zinc became very hard to find. Zinc was needed to make weapons. When Germany invaded Belgium, the price of zinc went up by a huge amount.

Because of this need, the construction of the Risdon Zinc Works began in 1916. It was built by a company called EZ Industries and opened in 1918. The factory's operations were connected to zinc mining in Rosebery and Williamsford.

Another company, Amalgamated Zinc Limited, started looking into making electrolytic zinc. Their manager, Herbert Gepp, researched the process in America. Tasmania offered cheap hydroelectric power, so the company decided to build their factory there. They signed a deal with the government for power.

In the 1920s, the factory grew very quickly. It became the largest zinc factory in the world. It held this title until the late 1930s. The suburb of Lutana was mostly built for the factory's workers. Pollution from the factory was a problem for the company and later owners.

In 1924, the factory started making superphosphate for fertilisers. They built furnaces to make sulphur dioxide, which is needed for sulphuric acid. They also began making ammonium sulphate to use the sulphuric acid they produced. By the mid-1970s, the factory was sending 70% of its products overseas.

Who Owns the Zinc Works?

The Risdon Zinc Works was sold as part of EZ Industries in 1984. It was bought by North Broken Hill Peko. Since then, the factory has been run by different companies. These include Pasminco and Zinifex. Since 2007, it has been owned by Nyrstar.

Environmental Impact and Pollution

Historically, materials stored outside the factory caused pollution. This pollution affected the soil on the site, in nearby suburbs, and in the River Derwent. Even with regular checks, the factory still releases some toxic heavy metals. These metals can affect the air, soil, and water around Greater Hobart.

Air Pollution from the Factory

A report in 2018 showed that Hobart had some air pollution. This was based on data from the National Pollutant Inventory. The report found medium levels of air pollution in certain areas. These areas included Lutana, Derwent Park, Moonah, and Glenorchy. The air pollution included gases like nitric oxide and nitrogen dioxide (together called NO

x ), and sulfur dioxide (SO2).

Soil Contamination in Local Areas

In the 1980s, soil samples from Lutana and other suburbs showed high levels of zinc, lead, and cadmium. Studies found that the wind direction and how close an area was to the factory affected how far the pollution spread.

Later samples in the 1990s showed that these metals were mostly in the top 50 mm of the soil. Most of it was in the very top 20 mm. A 2009 report by the CSIRO suggested a solution. It recommended growing vegetables like lettuce, spinach, and carrots in raised garden beds. These beds should have at least 30 cm of clean soil.

Water Pollution in the River and Ocean

The factory released methylmercury (mercury) and other heavy metals into the Derwent estuary. By the late 1970s, this made the Derwent one of the most polluted river systems in the world. Even today, deposits of zinc, mercury, cadmium, and lead remain. These metals are harmful to sea life and can build up in seafood.

Disposing of Jarosite in the Ocean

In the 1960s, a method was developed to remove iron from zinc. This process created a byproduct called jarosite. Jarosite contains iron and other harmful substances like cadmium, arsenic, mercury, and lead. From 1971 to 1997, the factory used this jarosite process.

Starting in 1973, the company began dumping jarosite into the southern ocean. This dumping site was about 60 nautical miles from Hobart. It was in very deep water, around 2 km deep. Research near the site found high levels of heavy metals in sea creatures. For example, fish and sea birds had higher levels of cadmium.

Between 1973 and 1997, the company was allowed to dump up to 2,400,000 tonnes of jarosite waste into the ocean each year. The exact amounts dumped each year are debated, but they were very large.

Greenpeace Protests Against Dumping

On March 14, 1990, activists from Greenpeace protested at the factory's docks. They climbed the masts of the dumping ship, MV Anson, and displayed a banner saying "Stop E. Z. Dumping." As the ship left, more protesters tried to board. There was a clash, and one activist was hurt.

The next day, police took four Greenpeace boats. They said the boats would only be returned if the protests stopped. In response, 250 people in 30 boats gathered to support Greenpeace. They demanded the return of the boats. The boats were returned the next day. The government minister, Ros Kelly, then announced better monitoring and research into other ways to get rid of waste.

Monitoring Water Quality

As part of its operating rules, Nyrstar must check the levels of toxic heavy metals in sea life from the Derwent estuary. This includes oysters, mussels, and flathead.

Data is collected every five years from the river. The monitoring covers areas from New Norfolk to the Iron Pot. However, Storm Bay and the nearby D'Entrecasteaux Channel are not included. In 2016, statistics showed that bream and shellfish caught in the river had high mercury levels and should not be eaten.

The Bridgewater Causeway's Role

Upstream from the factory, the convict-built causeway and Bridgewater Bridge act like a trap. They catch wastewater pollution from the factory. Further upstream, a paper mill also releases waste into the river. Studies in 2009, 2012, and 2020 found that sludge, wastewater, and heavy metals like cadmium, lead, zinc, and mercury could be disturbed by a new bridge construction project.

Groundwater Interception System

In 2010, a special system was built to stop pollution from reaching the groundwater. This is called the Groundwater Interception System (GIS). It was designed with the help of GHD Group.

The GIS has 13 long pipes buried underground. These pipes collect water that has flowed through the ground. The collected water then goes to a nearby wastewater treatment facility. This system works without pumps or electricity, making it easy to maintain. Each year, the GIS removes about 115 tonnes of zinc, 3 tonnes of cadmium, 7 tonnes of aluminium, and 332 tonnes of sulphate from the groundwater.

Factory Upgrades

In 2015, Nyrstar invested $52 million to make the factory more modern. This upgrade allowed them to process a wider range of metals. The Australian Government helped with a $29 million loan for this work.

In 2022, the Albanese Government gave $50 million for a larger upgrade project. This project is expected to cost $400 million in total. Nyrstar hopes these upgrades will help the factory produce up to 300,000 tonnes of zinc each year.

Incidents at the Factory

In 2012, people living in Lutana, Cornelian Bay, Risdon, and Lindisfarne had to stay indoors. This was because of a gas leak from a faulty part at the factory. The leak released sulphur trioxide and sulphur dioxide. Some parts of the factory were also evacuated.

In 2017, a worker was badly burned in an explosion while making zinc sheets. In 2019, a worker with over 30 years of experience died at the factory. The coroner's report found that he died of natural causes. In 2020, two workers were fired after a fight in the tearoom.

Connecting with the Community

Nyrstar Hobart has opened its doors to the public. In 2012, they were part of the Open Doors event. In 2013, they started inviting schools and educational groups to tour the factory. Nyrstar also launched a campaign called The Big Picture. This campaign used billboards, TV ads, a website, and social media. It aimed to show how important the factory is to Tasmania's economy.

How to Get There

The main entrance to the Risdon Zinc Works is on Risdon Road. You can also enter from the northern side via Derwent Park Road.

| Selma Burke |

| Pauline Powell Burns |

| Frederick J. Brown |

| Robert Blackburn |