Hammer facts for kids

A hammer is a basic tool used to hit things. It's often used to drive nails into materials like wood, or to break things apart. Most hammers have a long handle and a heavy head. The head usually has a flat side for hitting and sometimes a curved claw on the other side for pulling nails out. A common type of hammer is called a claw hammer.

A sledgehammer is a much larger hammer. It has a longer handle and a very heavy head, designed for two-handed use to deliver powerful blows.

Contents

Different Kinds of Hammers

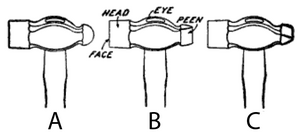

Hammers come in many shapes and sizes, each designed for a specific job. The most important part of any hammer is its head, which is a solid, heavy piece that delivers the impact without getting damaged itself. The part that hits the target is usually flat or slightly rounded. Some hammers have a special shape on the opposite end, like a ball (called a ball-peen hammer).

Some hammers are made from special materials. For example, if you're working near flammable gases (like in a chemical plant or coal mine), you can't use a regular steel hammer because it might create sparks that could cause a fire or explosion. In these places, people use "non-sparking" hammers made from metals like aluminium or beryllium copper.

Hammer handles used to be mostly wood, which is good at absorbing shock. Today, many handles are made from strong plastic or rubber.

Hammers You Hold

There are many types of hammers that people use by hand:

- Ball-peen hammer: Also called a mechanic's hammer, it has a rounded end (the "ball peen") used for shaping metal or hitting punches.

- Brass hammer: A "non-sparking" hammer used in places where sparks could be dangerous.

- Carpenter's hammer: This includes the claw hammer (great for driving and pulling nails) and the framing hammer (a heavier version for construction).

- Cross-peen hammer: Has one round face and one wedge-shaped face.

- Dead blow hammer: This hammer delivers a strong hit with very little bounce-back. Its head is often hollow and filled with sand or pellets to absorb the impact.

- Drilling hammer: A short-handled sledgehammer, often weighing 2 to 4 pounds. It was originally used for drilling into rock with a chisel.

- Engineer's hammer: A short-handled hammer, usually weighing 2 to 4 pounds. It was once a key tool for railroad engineers working on steam engines.

- Gavel: A small wooden hammer used by judges or people in charge of meetings to get attention.

- Geologist's hammer: Also called a rock pick, used by geologists to break open rocks and study them.

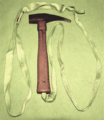

- Mallet: A hammer with a head made of wood, rubber, or rawhide. Mallets are used when you need to hit something without damaging its surface, like when working with furniture or delicate materials.

- Sledgehammer: A large, heavy hammer used for demolition or driving stakes.

- Upholstery hammer: A specialized hammer, sometimes with a magnetic face, used for putting small tacks into furniture during upholstery work.

Hammers Powered by Machines

Some hammers are much larger and are powered by machines. While they look different, they work on the same basic idea of delivering a strong blow.

- Hammer drill: A power tool that combines drilling with a jackhammer-like pounding motion to drill into hard materials like concrete.

- Jackhammer: A powerful tool that uses a hammering action to break up concrete or rock.

- Steam hammer: A very large industrial hammer powered by steam, used for heavy forging and shaping of metal.

- Trip hammer: An old type of machine-powered hammer, often used in blacksmithing, where a cam or lever lifts the hammer and lets it fall.

In modern carpentry, especially for framing buildings, many manual hammers have been replaced by nail guns, which can drive nails much faster. For upholstery, staple guns are often used instead of hammers.

Tools Used with Hammers

Hammers are often used with other tools to get the job done:

- Anvil: A heavy block of metal that blacksmiths use as a surface for hammering and shaping metal.

- Chisel: A tool with a sharp edge that is hit with a hammer to cut or carve materials.

- Punch: A tool used to make holes or indentations, often by hitting it with a hammer.

- Woodsplitting maul: A heavy tool that looks like an axe, used for splitting wood. It can be hit with a sledgehammer for extra force.

- Woodsplitting wedge: A metal wedge that is driven into wood with a sledgehammer to split it.

Images for kids

-

A modern claw hammer suited to drive and remove nails

-

Cartwheel mallets with heads of felt held between steel washers for use with timpani drums

-

A geologist's hammer used to break up rocks, as seen in archaeology and prospecting

-

A stone hammer found in Dover Township, Minnesota dated to 8000–3000 BCE, the North American Archaic period

-

16th-century claw hammer; detail from Dürer's Melencolia I (c. 1514)

See also

In Spanish: Martillo para niños

In Spanish: Martillo para niños

| Precious Adams |

| Lauren Anderson |

| Janet Collins |