Solid-state battery facts for kids

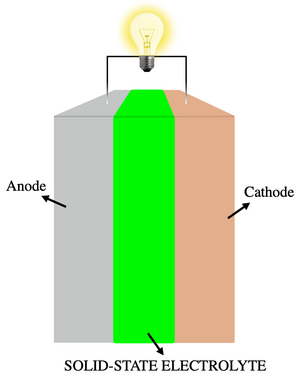

A solid-state battery with a solid electrolyte between two electrodes

|

|

| Specific energy | Thin film type: 300–900 Wh/kg (490–1,470 kJ/lb) Bulk type: 250–500 Wh/kg (410–820 kJ/lb) |

|---|---|

| Self-discharge rate | 6%ー85 °C (month) |

| Cycle durability | 10,000-100,000 cycles |

| Nominal cell voltage | Thin film type: 4.6 V Bulk type: 2.5 V, |

| Charge temperature interval | -20 °C 〜 105 °C |

A solid-state battery (SSB) is a special type of electrical battery. Unlike regular batteries that use a liquid or gel, solid-state batteries use a solid electrolyte. Think of it like a solid bridge that helps electricity move inside the battery. This makes them potentially much safer and able to store more energy than common lithium-ion batteries.

While solid electrolytes were first found in the 1800s, many challenges kept them from being widely used. But new discoveries in recent years have made people very interested in this technology again, especially for electric vehicles.

Solid-state batteries can use metallic lithium for the negative side (called the anode) and other materials like oxides or sulfides for the positive side (called the cathode). This design helps them store more energy. The solid electrolyte acts like a perfect barrier, letting only the right particles pass through. Because of this, solid-state batteries could solve many problems with today's liquid Li-ion batteries, such as fire risks, limited power, and not lasting as long.

Materials used for the solid electrolyte include ceramics (like oxides or sulfides) and solid polymers. You can already find solid-state batteries in pacemakers, RFID tags, and wearable devices. They are generally safer and can hold more power. However, challenges like cost, how long they last, and how they handle different temperatures are still being worked on.

Contents

How Solid-State Batteries Started

Early Discoveries

Between 1831 and 1834, a famous scientist named Michael Faraday discovered some solid materials that could conduct electricity. This was the very first step towards understanding how solid-state batteries could work.

Growing Interest (1900s-2009)

By the late 1950s, scientists were using solid materials in some electrical systems, but these batteries didn't store much energy and were expensive. In 1967, a big discovery of a material called beta-alumina helped kick-start the development of solid-state devices that could store more energy. Companies like Ford Motor Company and NGK started working on them.

Later, in the 1990s, scientists at Oak Ridge National Laboratory developed a new material called LiPON. This material was successfully used to make very thin lithium-ion batteries. However, these thin batteries were still costly to produce and had small capacities.

Modern Progress (2010-Present)

In 2011, scientists found a solid material, Li10GeP2S12 (LGPS), that could conduct electricity as well as liquids, even at room temperature! This was a huge breakthrough, making solid-state batteries much more competitive.

Many car companies became very interested in this technology for electric vehicles.

- In 2011, Bolloré launched electric cars using a type of solid-state battery.

- In 2012, Toyota began researching how to use these batteries in cars. Volkswagen also started working with companies specializing in this technology.

- In 2013, researchers at the University of Colorado Boulder developed a solid-state lithium battery with a new type of positive side (cathode) that promised higher energy.

- In 2017, John Goodenough, who helped invent regular lithium-ion batteries, showed off a new "glass battery." Later that year, Toyota and Panasonic teamed up to work on solid-state batteries. By 2019, Toyota held the most patents related to solid-state batteries, followed by BMW, Honda, Hyundai Motor Company, and Nissan.

- In 2018, Solid Power, a company started from the University of Colorado Boulder, received $20 million from Samsung and Hyundai to build a factory for its solid-state battery prototypes. Also in 2018, Qing Tao started the first Chinese production line for solid-state batteries.

- QuantumScape, a startup from Stanford University, went public in 2020. By 2023, they introduced a new lithium metal cell. Volkswagen's PowerCo confirmed that QuantumScape's prototype met its performance goals.

- In July 2021, Murata Manufacturing announced they would start mass production of small solid-state batteries for earphones and other wearable devices.

- Ford Motor Company and BMW invested $130 million in Solid Power.

- In September 2021, Toyota announced plans to use solid-state batteries in hybrid models starting in 2025.

- In February 2021, Hitachi Zosen Corporation announced tests on the International Space Station. In February 2022, a spacecraft launched to confirm that all-solid-state batteries would be tested on the ISS.

- In January 2022, ProLogium and Mercedes-Benz signed an agreement to develop and produce solid-state batteries.

- In early 2022, Swiss Clean Battery announced plans to open a factory for sustainable solid-state batteries by 2024.

- In July 2022, Svolt announced a new electric battery with high energy density.

- In June 2023, Maxell Corporation began mass production of large-capacity solid-state batteries. These batteries have a long life and can handle heat well.

- In September 2023, Panasonic showed a prototype solid-state battery for drones. It can charge very quickly and last for many cycles.

- In October 2023, Toyota announced a partnership with Idemitsu Kosan to produce solid-state batteries for their electric vehicles starting in 2028.

- In October 2023, Factorial Energy opened a battery factory and began sending samples to partners like Mercedes-Benz.

- In November 2023, Guangzhou Automobile Group announced they would use solid-state batteries in 2026, with mass production starting in 2025.

- In December 2023, Hyundai published a patent for a solid-state battery system that keeps constant pressure.

- In January 2024, Volkswagen announced that a prototype solid-state battery kept 95% of its power after 1000 charges, which is like driving 500,000 kilometers! It also passed other tests.

- In April 2024, Factorial signed an agreement with LG Chem and sent more samples to Mercedes-Benz.

What Solid-State Batteries Are Made Of

Solid-state batteries use different materials for their main parts. Scientists are always looking for better ones!

- Solid Electrolyte: This is the solid "bridge" that allows tiny charged particles (ions) to move between the battery's sides. Scientists use materials like ceramics (which are like pottery), glass, or special solid polymers. Some promising new materials include chloride superionic conductors, which are good at conducting ions and are flexible.

- Anode: This is the negative side of the battery. Often, it's made of metallic lithium. Using lithium here helps the battery store a lot more energy. Other materials like silicon or tin are also being explored.

- Cathode: This is the positive side. It can be made from materials like LiCoO2 or other lithium-based compounds. Scientists are also looking at materials like sulfur (in Li–S batteries) because it can store a huge amount of energy.

Scientists are also exploring new ways to improve these materials, like adding tiny carbon nanotubes to make connections better or using special coatings on cathode materials.

Perovskite Materials

Perovskite materials are also showing great promise for solid-state batteries. These materials are excellent at conducting ions and storing charge. They are used in many new energy technologies, including solid-state batteries and solar cells. Scientists are studying how to use them to make batteries safer and more efficient. For example, some perovskite materials have shown they can hold a lot of charge even after many uses.

Where We Use Solid-State Batteries

Solid-state batteries are already being used in some cool places, and they have a lot of potential for the future!

Powering Electric Vehicles

Electric vehicles (EVs) need powerful batteries to travel long distances. Solid-state batteries are lighter and can store more energy than current EV batteries. This means cars could go farther on a single charge, cost less to run, and be lighter. Many car companies, including Honda, Nissan, Toyota, and Mercedes-Benz, are investing heavily in developing these batteries for their future electric cars. Toyota, for example, has been working to use them in hybrid models since 2025.

Tiny Power for Wearable Devices

Imagine smaller, more reliable wearable devices like smartwatches or earbuds. Solid-state batteries are perfect for these because they are small, can hold a lot of power, and work well even in tough conditions. Murata Manufacturing started mass production of these small batteries for earphones in 2021.

Exploring Space

Space is a very harsh environment! In March 2021, Hitachi Zosen Corporation announced a solid-state battery they claimed had one of the highest capacities and a wider operating temperature range, making it suitable for space. A test mission was launched in February 2022. In August 2022, Japan Aerospace Exploration Agency (JAXA) announced that the solid-state batteries had worked properly in space, powering camera equipment in the Japanese Experiment Module Kibō on the International Space Station (ISS).

Flying Drones Longer

Drones can fly longer and carry more with lighter, more powerful solid-state batteries. A drone company called Vayu Aerospace noted an increased flight time after they used them in their G1 long flight drone. Another advantage for drones is that all-solid-state batteries can be charged quickly. In September 2023, Panasonic announced a prototype all-solid-state battery that can charge from 10% to 80% in just 3 minutes.

Powering Industrial Machines

All-solid-state batteries have long lifespans and excellent heat resistance. Therefore, they are expected to be used in harsh environments. Production of Maxell Corporation's all-solid-state batteries for use in industrial machinery began in 2023.

Portable Solar Power

In 2023, Yoshino became the first company to make portable solar generators using solid-state batteries. These generators can store 2.5 times more energy and provide double the power of older types, making them great for camping or emergencies.

What Makes Solid-State Batteries Tricky

Even with all their advantages, solid-state batteries still have some challenges that scientists are working to solve.

High Cost

Making thin solid-state batteries can be very expensive. It requires special equipment and processes that are difficult to scale up for mass production. This high cost makes them difficult to use in everyday products like phones or cars right now.

Temperature and Pressure Issues

Some solid-state batteries have historically had poor performance in very cold temperatures. Also, some types require high pressure to maintain good contact between their parts. If the pressure isn't right, the solid parts might break. However, scientists are making progress. In November 2022, a Japanese research group found a way to make solid-state batteries work stably without needing high pressure. In June 2023, another Japanese research group found a way to make a material called Li

3PS

4 work well at room temperature.

Connection Problems

A long-standing problem for all-solid-state batteries is high resistance where the positive side (cathode) meets the solid electrolyte. This "interfacial resistance" can make the battery less efficient. Scientists use special microscopes to look very closely at these connections and find ways to improve them. They also study how the battery materials change over time at these important connection points.

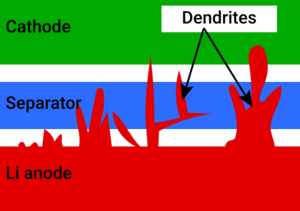

Tiny Spikes (Dendrites)

One big problem is the growth of tiny, tree-like spikes called dendrites on the lithium metal anode (the negative side). These spikes can grow through the solid part of the battery and cause a short circuit. This short circuit can lead to the battery losing power, overheating, or even being damaged. Scientists are working hard to find ways to stop these dendrites from forming. They are trying different materials and designs to make the battery safer and last longer.

Parts Changing Shape

When a battery charges and discharges, the materials inside its positive and negative parts (cathode and anode) can slightly change in volume. Imagine them swelling and shrinking a tiny bit. This change can create small gaps or cause parts to lose good contact with each other. When this happens, it makes it harder for electricity to flow, and the battery might not store as much energy. Scientists are looking for materials that don't change shape as much or ways to design batteries so these changes don't cause problems. For example, they might mix different materials that expand and contract in opposite ways to keep the overall change minimal.

Why Solid-State Batteries Are Awesome

Solid-state batteries have many exciting benefits that make them a big step forward in battery technology.

More Energy in a Smaller Space

Solid-state batteries can store much more energy than traditional lithium-ion batteries of the same size. This is largely because they can use metallic lithium for the anode, which holds a lot of charge. This means devices can be smaller, lighter, and last much longer. For example, electric cars could travel farther on a single charge.

Safer to Use

One of the biggest advantages is safety. Solid electrolytes are usually not flammable, unlike the liquids in traditional batteries. This greatly reduces the risk of the battery catching fire or overheating. Because they are safer, solid-state batteries don't need as many safety systems, which can also help them store even more energy in the same space. Studies have shown they generate much less heat during overheating events compared to traditional batteries.

Work in More Temperatures and Voltages

Solid-state batteries can work well in a wider range of temperatures, including hotter conditions, compared to traditional batteries. They can also handle higher voltages, which means they can deliver more power. This makes them suitable for high-performance devices and tough environments.

Faster Charging and Better Design

The solid electrolyte and lithium metal anode combination allows for faster movement of ions, which can reduce charging times compared to lithium-ion batteries. Also, these batteries can be stacked in a special way (called bipolar stacking) that makes the battery packs smaller and more efficient. This allows for improved overall energy use and gives designers more freedom to create new devices and vehicles.

Super Thin Solid-State Batteries

Background

The earliest thin-film solid-state batteries were developed in 1986. At first, this technology wasn't powerful enough for larger electronic devices. However, scientists have continued to improve them. By 2021, it was shown that very thin ceramic films, just 1 to 20 micrometers thick, could be made.

Structure

- Anode materials: Lithium is often preferred for the negative side because it can store a lot of energy. Alloys (mixtures of metals) like aluminum, silicon, and tin are also good choices.

- Cathode materials: The positive side needs to be lightweight, last through many charges, and store a lot of energy. Common materials include LiCoO2, LiFePO4, and others.

How They Are Made

These super thin batteries are made using special techniques, often involving "depositing" very thin layers of materials onto a surface. Imagine painting with atoms! Some methods include:

- Physical methods: These use processes like magnetron sputtering, where tiny particles are blasted onto a surface, or pulsed laser deposition, which uses powerful lasers.

- Chemical methods: These involve chemical reactions to build up thin films, such as electrodeposition or chemical vapor deposition.

What Makes Them Special

- High Energy in a Tiny Package: Even though they are thin, they can store a lot of energy for their size and weight. This is great for very small devices.

- Long-Lasting and Flexible: They can last a long time and can even be flexible, which opens up possibilities for new types of bendable electronics.

- Lightweight: Their thinness makes them very light, which is important for things like tiny sensors or medical devices.

What's Still Hard About Them

- Complex Manufacturing: Making them is still quite complicated and expensive, which limits how widely they can be used in everyday products.

- Connection Challenges: Getting all the super thin layers to connect perfectly can be tricky, affecting how much power they can deliver.

- Material Loss: When they charge and discharge, the tiny changes in volume can sometimes lead to a small loss of material, which can affect their performance over time.

Who Makes Solid-State Batteries

Many companies around the world are working on developing and producing solid-state batteries:

- CATL

- Cymbet

- Ilika

- Ionic Materials

- LG

- Panasonic

- Penghui Energy

- Sakti3

- Samsung

- Solid Power

- SolidEnergetics

- QuantumScape

- Large Power

New Ideas and Protecting Them

Scientists and companies are constantly coming up with new ideas for solid-state batteries. They file patents to protect these new inventions. A patent is like a special permission from the government that says only the inventor can make, use, or sell their invention for a certain period. This encourages companies to invest in research and development.

Companies like Toyota, LG, Samsung, Murata, and Panasonic are leading the way in getting patents for solid-state battery technology. Toyota, for example, received over 8,000 solid-state battery patents between 2020 and 2023! This shows how much effort is going into making these batteries better and safer for the future of transportation and other technologies.

According to a 2024 report from the WIPO, research and patenting activities in solid-state batteries have grown significantly and steadily between 2010 and 2023. This shows that solid-state batteries are a very important area within the broader field of battery technologies.

See also

- Anode-free battery

- Solid-state electrolyte

- Divalent

- Fast ion conductor

- Ionic conductivity

- Ionic crystal

- John B. Goodenough

- List of battery types

- Lithium–air battery

- Lithium iron phosphate battery

- Separator (electricity)

- Supercapacitor

- Thin-film lithium-ion battery