Michigan Limestone and Chemical Company facts for kids

|

|

| Public company | |

| Industry | Manufacturing, Mining |

| Founded | 1912 |

| Headquarters | Rogers City, Michigan, U.S. |

|

Key people

|

board of directors |

| Products | Chemicals, Mineral Products, and other Specialized Products and Services |

|

Number of employees

|

160 (2008) |

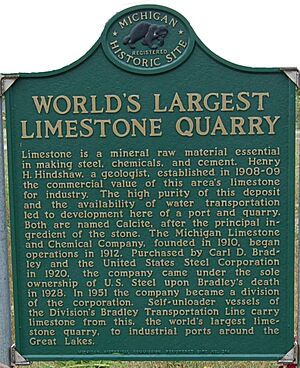

The Michigan Limestone and Chemical Company ran the world's biggest limestone quarry. A quarry is a large open pit where stone is dug out of the ground. This huge quarry is near Rogers City, Michigan in Presque Isle County, Michigan. It's also known as the "Calcite Quarry" or "Carmeuse Lime and Stone."

The company started in 1910, but they began digging limestone in 1912. The quarry has had different owners over the years. Today, it is still one of the largest places that produces limestone in the United States. Getting the limestone from the quarry to other places relied heavily on ships on the Great Lakes and trains.

The limestone dug from this quarry is found underground in northern Michigan. It's located near Alpena, Michigan and south of Rogers City, right by the shore of Lake Huron. Limestone is a very important raw material used in many industries. It's used for things like building roads, making cement, and helping to make iron and steel. It's also used in farming to help soil and in making sugar.

Contents

History of the Limestone Quarry

In January 1909, a mining expert named Henry H. Hindshaw from New York City began studying the limestone in northern Lower Michigan. He checked out land between Rogers City and Crawford's Quarry. In February, Hindshaw took samples for the Solvay Process Company. The limestone was good enough to be used by businesses. So, the company decided to buy all the land around the Lake Huron shore south of Rogers City.

Hindshaw then met with William F. White, an investor. White was interested in developing the limestone for business. Hindshaw first thought the limestone could be used as building material. But he soon realized it was more valuable for its chemical composition.

Limestone is a key material for many industries. It's used for road building, cement, and in making iron and steel. Hindshaw found that the limestone near Rogers City was very pure and high-quality. Its location near Lake Huron also meant it could be easily shipped. This led to the creation of the quarry and a port. Both the quarry and the port were named "Calcite," after the main part of limestone.

The Calcite Quarry Today

This quarry is the largest limestone quarry in the world. It is about 4 miles long and 1.5 miles wide, covering 8,924 acres. Giant trucks are used here. These trucks can carry up to 195 tons of rock in one load. Their tires are about 13 feet tall!

Today, the quarry and plant are owned by Carmeuse Lime and Stone. About 115 people work there. Some people have called the quarry a "man-made Grand Canyon" because it is more than 150 feet deep.

This quarry is one of many limestone quarries in Michigan. The "Michigan Basin" has large areas of limestone rock underground. The quarry digs up limestone and dolomite rock layers. These layers are part of the "Michigan Basin" and the "Rogers City" rock formations.

This open pit mine has been running for 113 years since 1912. It has been called "the Calcite Quarry" and "Carmeuse Lime and Stone." It mines deposits that are 350 million years old. Over 750 million tons of limestone have been shipped from here. About 3,000 of the 7,000 acres on the site are actively mined. The company believes there is enough limestone to last another 100 years.

The quarry is so big that it has been photographed by astronauts from space. It was also featured in a documentary film that won an Emmy Award. The film's director said, "It's a human story. The quarry is rock, but it's how this natural resource becomes a driving force for our nation." Much of this limestone helped build the Mackinac Bridge and the interstate highway system across the country. It's also used in many everyday items.

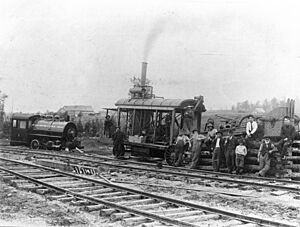

The Detroit and Mackinac Railway built a train line to Rogers City in 1911. Trains have been used inside the mine since before 1926. Today, the railroad for the quarry is run by Lake State Railway.

Rogers City gave land to create a landmark celebrating the quarry's 100th birthday. Part of this landmark is a 6-foot by 6-foot mural made of outdoor tiles. It shows the history of the quarry by showing layers of rock from different time periods.

The United States Army and United States Air Force sometimes practice military exercises in the Carmeuse Calcite Quarry area.

This quarry produces high-calcium limestone. It ships between 7 and 10.5 million tons each year, depending on what the market needs. The quarry makes nine different sizes of limestone products. These can be mixed to meet specific needs.

The Company's Beginnings

William White and other investors started the Michigan Limestone and Chemical Company in 1910. They bought 5,000 acres of land with lots of limestone from the Rogers City Land Company. Before this, the lumber industry was the main business in Rogers City. But by the early 1900s, most of the trees had been cut down. The lumber companies were moving to new forests. Around this time, the Michigan Limestone and Chemical Company began building its mining facilities.

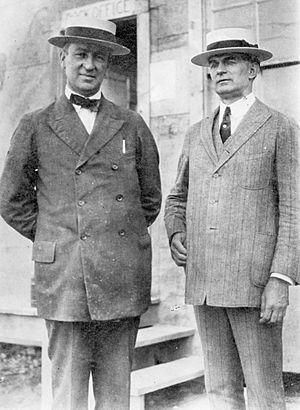

White, who lived in New York City, became the company's president. The company officially started on May 26, 1910. The Calcite port and quarry plant began operations in June 1910. They had offices in New York City and Rogers City. Henry Hindshaw was the first general manager. Carl D. Bradley took over as manager in October 1911.

Bradley oversaw the building of the limestone processing factory. This included a powerhouse, a stone crusher, and a harbor for loading ships. They bought steam shovels for digging and steam locomotives to move the stone.

The company built a 14-mile train track to connect the Calcite operations to the main Detroit and Mackinac Railway line. Limestone production started in early 1912. The first shipments of stone went out by steamer ships in June of that year. The company received more orders for limestone than they expected!

Most of the stone from Rogers City was shipped on lake freighters to steel mills. These mills were located along the lower Great Lakes in places like Detroit and Cleveland. For many years, the biggest customer was United States Steel (U.S. Steel). Later, new uses for the limestone were found in farming, construction, and chemical industries. Rogers City grew as the Calcite plant expanded. Within 20 years, the quarry at Rogers City was the world's largest producer of limestone.

Becoming Part of U.S. Steel

United States Steel Corporation was the first customer of the Michigan Limestone and Chemical Company. Even before the company officially started, White and his partners talked to big companies that used limestone. They believed that if they built a huge quarry, they would have customers right away. U.S. Steel signed a contract within months of the company forming.

U.S. Steel later bought a controlling share of Michigan Limestone in 1920. At that time, the company was producing 1,000 tons of crushed limestone every day.

Carl Bradley became president of Michigan Limestone. He also led Michigan Limestone's fleet of self-unloading ships. These ships were part of the Bradley Transportation Company. After Bradley passed away in 1928, U.S. Steel took full ownership of both Michigan Limestone and Bradley Transportation. They became part of U.S. Steel. In 1951, the Rogers City operations became U.S. Steel's "Northern District." The company is still a major employer in northern Michigan. Its ownership has changed a few times recently.

Uses of Limestone

The limestone from Michigan Limestone is a white chemical called calcium carbonate. It has very low levels of other elements like iron or silica. Steel mills add limestone to hot, melted iron in blast furnaces. It helps remove impurities when making steel.

Limestone is also widely used to make cement. When limestone is heated to very high temperatures (up to 2,300 degrees Fahrenheit), it turns into pure lime. Lime is used in many products, including paints, sugar, glass, and baking powder. It's also used to make chemicals like soda ash and for softening water. Limestone was even used to fill the supports for the Mackinac Bridge.

Crushed limestone is used in farming to add lime back into the soil. When crops are grown continuously, the soil can lose its lime and become acidic. Crops don't grow well in acidic soil. Crushed limestone helps restore the lime, making the soil balanced. This allows plants to absorb more nutrients through their roots. This type of soil conditioner is called agricultural lime. While lime isn't a fertilizer itself, it can be used with fertilizers. Agricultural lime also helps land used for farm animals like cows. Bones need calcium to grow, and milk has a lot of calcium. Farmers often use agricultural lime on their fields because it helps increase milk production.

Limestone is also essential for making white sugar from sugar beets. Michigan is a big producer of beet sugar.

Self-Unloading Ships

Between 1912 and 1917, Michigan Limestone and Chemical Company built three special ships. They were named SS Calcite, SS W.F. White, and SS Carl D. Bradley. These ships were "revolutionary" because they could unload themselves.

In 1912, the company built its first steamship, the SS Calcite. It was much larger than the first modern self-unloader on the Great Lakes, the SS Wyandotte (built in 1908). The Calcite carried limestone from Rogers City to Buffalo and Fairport, New York. The ships W.F. White and Carl D. Bradley were built in the following years. All these ships had grey hulls to hide the limestone dust that would collect during loading and unloading.

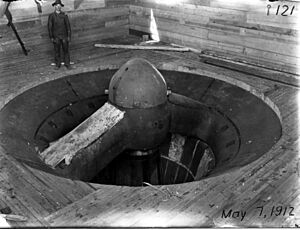

The design of these early ore carrier self-unloaders is similar to today's ships. The cargo hold inside the ship has sloped sides that lead to the center. At the bottom, steel gates can open. This allows the material to drop onto a conveyor belt running along the ship's length. This belt carries the material up to another belt. This second belt goes up to the main deck and then through a long boom. This boom swings out over the ship's side to unload the material onto the customer's dock. The great thing about self-unloaders is that they can deliver limestone directly to a dock without needing expensive equipment on shore to unload them.

As the company grew, it built more of these self-unloading ships. After 1920, these ships were operated by the Bradley Transportation Company. They were known as the Bradley boats or the Bradley fleet. Today, self-unloaders still carry limestone from the Calcite plant to industrial ports all around the Great Lakes.

Sadly, the SS Carl D. Bradley was lost in a storm in November 1958. It was returning from delivering a load of limestone. 33 of the 35 crew members died. Most of them lived in or near Rogers City. This was the biggest loss of life in the Great Lakes freighter fleet since that time. Ships like the SS Carl D. Bradley would carry limestone to steel mills in Gary, Indiana.

Michigan Historical Marker

The company offers yearly tours of the quarry. These tours often happen during Rogers City's annual Nautical City Festival. People can see the giant equipment used at the plant up close. This helps visitors understand how massive the operation is.

The Calcite Operation is one of 28 production facilities that Carmeuse owns in North America. It's also one of 94 facilities the company owns worldwide. The plant mines, processes, and ships limestone using freighters on the Great Lakes. As of 2019, over 915 million tons have been shipped from the quarry. The highest production year was 1953, with 16.6 million tons. In the past, leftover materials were dumped into the lake, but now they are used in helpful ways. It would take 4,000 wheelbarrows to fill the largest truck at the facility. It takes 12 hours to fill a freighter.

There are good spots around the quarry to view it.

This site is part of a larger history of limestone mining in Michigan. For example, the Mill Creek Quarry opened near Mackinaw City, Michigan in 1912. That site is now part of the Michigan state parks system.

There is a Michigan State Historic Site historical marker at a viewing point overlooking the Michigan Limestone and Chemical Company facilities.

See also

- Alabaster Historic District

- Exercise Northern Strike

- List of types of limestone