Soulé Steam Feed Works facts for kids

|

Soulé Steam Feed Works

|

|

|

U.S. Historic district

Contributing property |

|

Main factory in 2010

|

|

| Location | 1806–1808 4th St and 1803–1809 5th St, Meridian, Mississippi |

|---|---|

| Built | 1891 |

| Part of | Union Station Historic District (ID79003731) |

| MPS | Meridian MRA |

Quick facts for kids Significant dates |

|

| Designated CP | December 18, 1979 |

The Soulé Steam Feed Works is a historical company that started in Meridian, Mississippi, in 1892. It was officially made a business in 1893 by a man named George Soulé. Its buildings are part of the Union Station Historic District, which was added to the National Register of Historic Places in 1979. It was also named a Mississippi Landmark in 2003.

This company was famous for its many new ideas in steam engine technology. It was most successful around the early 1900s, selling its products all over the world.

In 2004, the Mississippi Industrial Heritage Museum took over the complex. The museum now runs an annual Soulé Live Steam Festival there. This festival brings thousands of people from across the country to Meridian.

Contents

George Soulé: The Founder

George Wilberforce Soulé, who started Soulé Steam Feed Works, was born in Buffalo, New York, in 1849. He was a descendant of another George Soule who traveled to America on the Mayflower ship. When he was one year old, George and his father moved to Wisconsin.

When George was 20, his father died. He decided to leave the family farm and find his own way. Even though he had less than a year of formal schooling, he taught for three months. Then, in 1875, he moved south to Morton, Mississippi. He had missed a ship to Cuba but stayed in Morton and Shubuta, Mississippi, for a while. In 1879, he moved his businesses to Meridian.

Before starting Steam Feed Works, Soulé ran other companies in Meridian. These included a turpentine company, a lumber company, a cotton gin, and a business that represented manufacturers. In 1876, before moving to Meridian, he was in a train accident. He lost his left leg and four toes on his right foot.

Early Inventions and Businesses

George Soulé started two other companies before Steam Feed Works. These were the Southern Standard Cotton Press Company and the Progress Manufacturing Company. After his train accident, he didn't have much money. So, he decided to build his own cotton press for his new cotton gin.

His invention was simpler and cheaper than others on the market. It quickly became very popular. Soulé named it the Southern Standard Cotton Press and built a company around it. By 1881, two years after moving to Meridian, his company had sold 750 cotton presses across the South.

In 1886, Soulé sold the Southern Standard Press. He then started Progress Manufacturing in 1894 and invented the Ideal Hay-Press for this new company. This business was located on 5th Street. It grew to include a foundry (a place where metal is melted and shaped) and a machine shop.

Soulé wanted to invent more things. In 1888, he handed over the daily running of Progress Manufacturing to others. He began working on a small rotary engine. He sold Progress Manufacturing in 1891 and then started Steam Feed Works. The business officially became a company in 1893. During his life, Soulé received patents for over 40 inventions. These included the Success Cotton Seed Huller and an improved sugar mill.

Later Life and Family

By 1902, Soulé Steam Feed Works was doing very well. George Soulé found a country home in Santa Rosa County, Florida. He started to let his son, Clyde, take over more of the company's work. George spent more time in Florida.

He returned to Meridian in 1917 and stayed there until he passed away on December 21, 1922. George Soulé was married twice. First to Olivia Sherman Warren in 1873, and then to Constance Gara in 1907, after his first wife's death. He had nine children. One of his grandchildren, also named George Soulé, became a well-known R&B songwriter in the 1960s and 70s.

The Steam Feed Works Complex

The Soulé Steam Feed Works was first located at 25th Avenue and 5th Street. The first building on the company's current site was built between 1890 and 1892. It used to be the Meridian Candy Factory. After a fire badly damaged it, George Soulé bought it. He turned it into a machine shop, assembly area, and office for his growing business.

The two-story building originally had a brick front. But in the 1930s, a layer of lime cement stucco was added. Another layer was put on in the late 1960s. Inside the building, there is a fireproof vault that is 8 by 12 feet. This vault still holds the company's original records. The company's name is written in gold above the vault. This vault was added after a fire in 1895 destroyed George Soulé's office and his records.

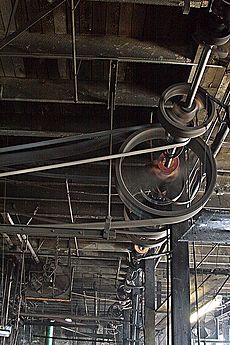

In 1907, a second building was added next to the original one. The downstairs of the first building was changed into a mill supply store. Machines in the building are powered by belts connected to a 100-foot line shaft. This shaft runs almost the entire length of the building. It is now the longest operating line shaft in the country. An electric motor from the early 1920s powers it.

The building also has a blacksmith shop with two forges. Both are powered by the line shaft. A wooden freight elevator, also belt-driven, was used to move finished metal parts upstairs to the assembly room. It then lowered the finished products back downstairs. A system of rails and cranes helped move heavy machinery and other items easily to the elevator and around the building. This crane system could also move items to the foundry (built in 1917), the machine shop, and out to the street.

On the second floor, there is a steam engine factory. It has another 25-foot shaft that was driven by the main shaft downstairs. Fans were attached to this smaller shaft to keep the area cool in the summer.

In October 1907, when the second building was constructed, Soulé had 23 employees in the foundry and 23 machinists, making 46 workers in total. By May 1917, the number dropped to 31 because of fewer available workers during World War I. However, employee numbers went up again after the war. Between 1922 and 1945, the company usually had about 50 workers.

Employees were paid an average of 50 to 70 cents per hour. These were some of the highest-paying jobs in Meridian at that time. The foreman and supervisors received an extra $7–9 in cash each week. Workers were on duty six days a week, usually for nine hours a day.

A third building, the foundry, was added to the complex in 1917. More parts were added to it from 1923 to 1925. A cupola furnace, which was older than the building itself, was put in near the western end. It was used to melt iron until a modern electric furnace was added in the 1970s. Both furnaces are still in the building and can be used at the same time. In 1977, a Vulcan Engineering NoBake System was also added. A fourth and fifth building were built in the 1920s. These were only used for storage and did not add to the factory's ability to make things.

During its busiest time, the company made and shipped many products around the world. But after World War II, the company focused on selling to local and regional customers. In the 1950s, the upstairs of the original 1892 building was turned into storage. Other changes were made in the later 1900s. These included dividing the office space into cubicles, covering walls with Masonite board, and covering floors with sheet vinyl. The Mississippi Industrial Heritage Museum received ownership of the building in December 2003. They have largely restored the building to how it looked in the 1920s.

Products Made at Soulé Steam Feed Works

The company is best known for helping the lumber industry. This industry grew a lot from about 1885 to the 1930s. Around the year 1900, steam was the only portable and reliable source of power. The Soulé Rotary Steam Engine was patented in 1896. From 1892 to 1922, this engine was used to power sawmill carriages. These carriages helped feed lumber into a spinning saw blade.

The engine could also power winches. Winches are machines used to load and unload logs from railroad cars and wagons. A total of 2,300 of these engines were built at the factory and sold worldwide. A few are still working today in Australia and India. These engines were also sold in countries like South Africa, Cuba, Ecuador, Mexico, the Philippines, Brazil, Canada, New Zealand, Peru, Venezuela, and Colombia.

Even though the engines were called "the most durable and easily controlled" of their time, some people called them "steam hogs." This was because they needed a lot of steam to run. Soulé patented an improvement to the rotary engine in 1902. However, more improvements were needed to keep up with other companies.

The Spee-D-Twin Engine

The Soulé Spee-D-Twin was a two-cylinder steam engine designed in 1922 and patented in 1923. It was much more efficient than the older rotary engine. The Spee-D-Twin quickly became a favorite among sawmill operators. This engine had a special valve that allowed it to operate both forward and backward. Its small size meant it could be added to existing sawmill carriages.

When the factory was running at full speed, it could produce one Spee-D-Twin every day. The company built and sold 4,301 Spee-D-Twins between 1923 and 1984. They were sold to people in all fifty states and in other countries too.

Other Inventions

Soulé Steam Feed Works also patented the Simplex Automatic Lumber Edge Stacker in 1897. This machine helped automate the process of stacking lumber. The first Edge Stacker was installed in a mill in Lumberton, Mississippi, in July 1895. More than 100 were installed across the nation. Some famous mills that used Soulé Stackers included the Great Southern Lumber Company in Bogalusa, Louisiana, and the Potlatch Lumber Company in Elk River, Idaho.

Other products made and sold by Soulé Steam Feed Works included the St. Bernard Saw Mill Dog. This device allowed mills to cut lumber from both large and small logs. An employee named A.D. Hunter invented a plane-to-plane air refueling device while working there. This device was used during Fred and Al Key's record-breaking endurance flight in 1935. Another employee, David Stephenson, made the aluminum walkway used during the flight for plane maintenance.

Soulé Live Steam Festival

The Mississippi Industrial Heritage Museum started holding the Soulé Live Steam Festival in October 2003. This festival shows off the history of steam engines, which the company is famous for. The festival has grown every year since it began. It is the only steam show in the United States held at an actual steam engine factory.

The 2008 festival brought nearly 2,000 people from 10 states to downtown Meridian. A Watts-Campbell Corliss steam engine, built in 1905, was offered to the Smithsonian Institution in Washington, D.C.. But they already had one, so it was given to the Mississippi Industrial Heritage Museum. It was installed during that year's festival. The museum also owns the very last steam engine ever built by the company.

The seventh annual festival in 2009 attracted several thousand visitors from 15 states and one foreign country. The event was also made longer, lasting two days. During the festival, the Watts-Campbell Corliss engine from 2008 was shown working. An 1870 Manchester engine was also demonstrated. Other steam engines were brought in by the public and put on display. A portable sawmill was also demonstrated.

Other demonstrations that happen regularly at the festival include blacksmithing, broom-making, and pottery wheel demonstrations. There is also an antique print shop that operates. Most of the displays at the festival have working examples that blow whistles, let out steam, and cut logs. Alabama Art Casting used to hold annual molten iron pours at Soulé until recent years.

| William Lucy |

| Charles Hayes |

| Cleveland Robinson |