Avonmouth Docks facts for kids

Quick facts for kids Avonmouth Docks |

|

|---|---|

|

|

| Lua error in Module:Location_map at line 530: Unable to find the specified location map definition: "Module:Location map/data/Yes" does not exist. | |

| Location | |

| Country | United Kingdom |

| Location | Mouth of the River Avon, Bristol, England |

| Coordinates | 51°30′18″N 2°42′25″W / 51.505°N 2.707°W |

| Details | |

| Opened | 1877 |

| Operated by | The Bristol Port Company (150 year lease from 1991) |

| Owned by | Bristol City Council |

| Type of harbor | Artificial |

| Website http://www.bristolport.co.uk/ |

|

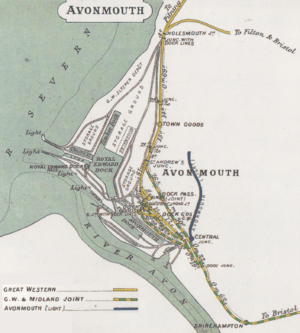

The Avonmouth Docks are an important part of the Port of Bristol in England. They are located on the northern side of the River Avon's mouth. This is where the river meets the larger Severn estuary, in an area called Avonmouth. On the opposite side of the river is the Royal Portbury Dock.

To enter the docks, ships pass through a large lock. This lock is 210 meters (689 feet) long and 30 meters (98 feet) wide. Today, Avonmouth Docks is one of the UK's main ports for chilled foods. This includes lots of fruit and vegetables. Goods can be moved to and from the docks by road using the M5 motorway. They can also be moved by train using the Henbury Loop Line. People can reach the docks by train at Avonmouth railway station on the Severn Beach Line.

Contents

Why Avonmouth Docks Were Built

Bristol Harbour was once a very important trading center in the UK. Its location in the west of the country was perfect. It allowed ships to easily reach both the Atlantic Ocean and the Mediterranean Sea. Ships also traded along the coast. Areas like "Welsh Back" were busy with small boats called trows. These boats carried goods like slate, stone, wood, and coal.

However, by the 1700s, docks in Liverpool grew much larger. This created more competition for Bristol, especially in the tobacco trade. Bristol's old docks had problems. They were not big enough for larger ships. In 1802, a plan was made to improve Bristol Harbour. A dam and lock were built to create a "floating harbour." This meant the water level inside the harbour stayed the same, no matter the tide. This big project cost a lot of money and opened in 1809.

But these improvements were very expensive. This made it harder for Bristol to compete with Liverpool. By 1867, ships were even bigger. The bends in the River Avon made it impossible for ships longer than 91 meters (300 feet) to reach the harbour. So, new docks were planned at Avonmouth and Portishead. These new docks were much cheaper to build. The current entrance lock at Avonmouth was designed by Thomas Howard. It opened in 1873 and was 19 meters (62 feet) wide.

History of the Docks

How the Docks Developed

The Avonmouth Docks Co. was created to build new docks at Avonmouth. This was because of the many challenges of building along the River Avon. The new docks, now called Avonmouth Old Dock, opened in 1877. A railway line, the Bristol Port Railway and Pier (BPRP), was also built. This railway ran from Hotwells to Avonmouth. It helped move goods to and from the docks. Bricks for the docks were made by a company called Crown Brick Works.

Connecting by Rail

At first, the BPRP railway was separate from the main national railway network. It was only meant for local transport. Extending it to Bristol's main station, Bristol Temple Meads, would have been too expensive. Instead, a new link was planned from the BPRP at Sneyd Park. This link would go under Clifton Down to connect with the main railway lines.

This connection was approved in 1867. However, the BPRP company had money problems. They couldn't finish the line. Two big railway companies, the Midland Railway (MR) and the Great Western Railway (GWR), became interested. They were competing fiercely. To control the port facilities, the Bristol Corporation bought Avonmouth Docks and the BPRP in 1884.

The new railway line, called the Clifton Extension Railway, opened in 1874. It helped connect the docks to the wider railway network.

The Royal Edward Dock

The Royal Edward Dock was designed by famous engineers Benjamin Baker and John Wolfe-Barry. Work on this dock began in 1902. The then Prince of Wales (who later became King Edward VII) started the project. It included building a 267-meter (876-foot) dry dock. The whole complex was officially opened by King Edward VII in 1908.

The Royal Edward Dock runs from south to north along the River Severn. It is the largest of the three docks that make up the Port of Bristol. Over the years, the dock facilities have been updated. By 1911, 27 oil storage tanks were added. New grain silos were built in 1928. During World War II, the docks were made even bigger. More facilities for unloading oil and petrol were added. A new pipeline was also built to supply oil to London.

By the 1960s, container ships became much larger. They could no longer easily navigate the River Avon to reach the Royal Edward Dock. This led to the planning of the Royal Portbury Dock on the south bank. Many old warehouses at Avonmouth were turned into homes. But the remaining dock areas were updated for new types of cargo. Today, these docks handle things like scrap metal, sand and gravel, vegetable oil, and coal. They also have container services to places like Ireland, Europe, and Scandinavia. All these services are connected to the rail network by the Henbury Loop Line.

Mustard Gas Production

During the later part of World War I, there was a plan to make Avonmouth a center for producing mustard gas. This chemical weapon was against international agreements. However, under special government rules, the Ministry of Munitions took over many small metal factories. They formed a new company called the National Smelting Company (NSC). Before World War I, much of Britain's zinc came from Australia but was processed in Germany. So, the NSC was asked to build a new zinc processing plant and sulphuric acid plant at Avonmouth.

Construction of this chemical plant began in 1917 and finished in 1923. It cost £800,000. The plant started working in spring 1918. It produced a chemical agent that was then put into shells on site. Although the first products arrived in France just two months before the war ended in November 1918, they were used in battle. By November 1918, a nearby factory had produced over 85,000 mustard gas shells.

Producing mustard gas was very dangerous for the workers. In December 1918, a doctor at the plant reported that 1,400 illnesses happened among the 1,100 workers, mostly women. These illnesses were directly caused by their work. Sadly, three people died from accidents, and four died from related illnesses. There were also 160 accidents that caused over 1,000 burns.

Britannia Smelting Works

After World War I, the need for zinc and sulphuric acid dropped a lot. The National Smelting Company (NSC) faced problems. It was then taken over by British business people interested in metals and chemicals. In 1929, an Australian company bought the NSC. This company later merged with another to become Consolidated Zinc. The smaller NSC plants were closed. Production was focused on Avonmouth, which became known as the Britannia smelting works. Here, a famous new way to process zinc was developed. By 1967, the Avonmouth Works had the largest and most efficient zinc blast furnace in the world.

Consolidated Zinc later merged with the Rio Tinto Company, a mining company. This new company became the Rio Tinto Group we know today. Over time, it became cheaper to process metals in other parts of the world. So, the Avonmouth site stopped production in the 1970s. It remained open as a storage and distribution center until 2003.

In 2012, a company called SITA UK started to redevelop the site. However, construction workers began to show symptoms similar to mustard gas exposure. The Ministry of Defence was called in to check the site. Even after their approval, workers later found a mustard gas shell. This shell was safely removed by experts. The site was closed for a year while more tests were done. In late 2013, the Ministry of Defence gave full clearance. This allowed the site to be redeveloped. It is now a large distribution center for Asda supermarkets and a recycling plant for SITA UK.

How the Docks Operate Today

The docks were managed by the Port of Bristol Authority, which was part of Bristol City Council. But in 1991, the council gave a 150-year lease to the Bristol Port Company. This company now operates both Avonmouth Docks and Royal Portbury Dock.

Bulk Coal Terminal

The docks have a special terminal for unloading imported coal. This coal comes from both the Royal Edward and Royal Portbury docks. A rail-loading system, managed by DB Cargo UK, helps move the coal. At the Royal Edward Dock, a large crane can unload up to 10,000 tonnes of coal every day. At Royal Portbury, two fast conveyors move 2,500 tonnes of coal. This coal goes into a conveyor system that runs under the River Avon in a tunnel. Freight trains move slowly under the bunkers. This allows a 1,750-tonne train to be fully loaded in less than 36 minutes.

See Also

- Port of Bristol

- Royal Portbury Dock

Images for kids

| Delilah Pierce |

| Gordon Parks |

| Augusta Savage |

| Charles Ethan Porter |