Cheesemaking facts for kids

Cheesemaking is the skill of making cheese. It's a way to preserve milk, keeping its goodness and value for a long time. Cheesemaking also lets us create many different kinds of cheese, each with its own unique taste and texture.

Contents

History of Cheesemaking

People have been making cheese for a very long time! We know this from old Egyptian tomb drawings and ancient Greek writings.

Cheesemaking might have started with nomadic herdsmen. These people moved around with their animals. They stored milk in containers made from sheep and goats' stomachs. These stomach linings had natural ingredients like lactic acid, bacteria, and rennet. These things made the milk ferment and turn solid, forming curds.

This process would have created something like yogurt. By gently stirring it and separating the solid curds from the liquid whey, they would have made cheese. Cheese is mainly the milk protein called casein and milk fat. The whey proteins and lactose (milk sugar) are removed in the whey. Another idea is that cheese started from unwashed milk buckets. These buckets would have had the right bacteria to begin the cheesemaking process.

Ancient Cheesemaking Tools

Some of the oldest tools for making cheese were cheese molds or strainers. These have been found all over Europe and date back to the Bronze Age. Early cheesemakers used baskets to separate the curds. Later, they used molds made of wood or pottery.

Cheesemakers would put the curds inside the mold and press them. This squeezed out the whey through holes in the mold. The more whey that was removed, the firmer the cheese became. In ancient Ireland, cheeses ranged from very dry and hard to almost liquid.

People often used designs on their cheese molds. These patterns helped decorate the cheeses and tell them apart. Many monasteries and abbeys owned milk animals. So, the cheeses they made often had a cross in the middle.

Today, most cheese is made from cow's milk. But in ancient times, goat's milk was often preferred. Goats are smaller than cows, so they needed less food. They were also easier to move around. Plus, goats can have babies and produce milk all year. Sheep, another milk animal, only mate in the fall and winter.

How Cheese is Made

The main goal of cheesemaking is to control how milk changes into cheese. Milk usually comes from a cow, goat, sheep, or buffalo. Cow's milk is the most common worldwide. Cheesemakers want to make a consistent product. This means it always has the same look, smell, taste, and texture. For example, making Camembert cheese is similar to making Cheddar, but with some key differences.

Sometimes, cheeses are left to ferment naturally. This happens from tiny spores and bacteria in the air. This method can lead to unique cheeses, but they might not always be exactly the same.

Adding Cultures

To make cheese, milk is heated in a large vat. This temperature helps good bacteria grow. These bacteria eat the lactose (milk sugar) and turn it into lactic acid. These bacteria can be naturally present in unpasteurized milk. Or, cheesemakers can add them from a special culture of "starter" bacteria.

Some bacteria only make lactic acid. These are used for cheeses like Cheddar, which need a clean, acidic taste. Other bacteria make lactic acid plus other things like carbon dioxide gas. These are used for cheeses like Emmental. The gas creates the famous "eye holes" in the cheese. These bacteria also give Emmental its fruity flavors.

Starter cultures are chosen carefully to give each cheese its special qualities. For cheeses like Stilton, Roquefort, or Camembert, which have mould, tiny mould spores can be added to the milk. Or, they can be added later to the cheese curds.

Making the Curd (Coagulation)

After enough lactic acid has formed, rennet is added to the milk. Rennet contains an enzyme that makes the milk protein, casein, clump together. This forms the solid cheese curd. The milk fat gets trapped within this solid curd. After adding rennet, the milk is left alone for a while to let the curds form.

Draining the Whey

Once the curds are ready, the liquid whey needs to be removed. Water and bacteria can cause food to spoil. So, most of the water (whey) must be taken out of the curds. This helps to dry the cheese. There are several ways to separate the curds from the whey.

Scalding and Pressing

For hard cheeses like Cheddar, the curds are cut into small cubes. Then, the temperature is raised to about 39 degrees Celsius (102 degrees Fahrenheit). This process is called 'scalding'. It helps more whey come out of the curds. The curds and whey are often moved to a cooling table. This table has screens that let the whey drain away, but keep the curds.

The cheesemaker then cuts and stacks the curds. This process is called 'cheddaring'. It helps release even more whey. During cheddaring, the curds become more acidic. Next, the curds are cut into ribbon shapes. Salt is mixed in to stop the acid from developing further. The salted curds are then put into cheese molds lined with cheesecloth. They are pressed overnight. This makes the curd pieces stick together.

After pressing, the cheese blocks are removed from the molds. They are either wrapped in cloth, waxed, or vacuum packed in plastic bags. Then, they are stored to mature. Vacuum packing removes oxygen and stops mould from growing. This is important for some cheeses, but not for others.

Mould-Ripening Cheeses

Making cheeses like Camembert is different from making Cheddar. The curds are handled very gently. They are carefully placed into special hoops. The whey is allowed to drain out by gravity, usually overnight. Then, the cheese curds are taken out of the hoops and soaked in a salty water solution. The salt helps stop bacteria from growing, just like with Cheddar.

If mould spores were not added to the milk, they are now put onto the cheese. This can be done by spraying the cheese with a mix of mould spores and water. Or, the cheese can be dipped into a bath containing spores, like Penicillium candida.

The cheese then goes through several maturation stages. The temperature and humidity are carefully controlled. This allows the surface mould to grow and helps the cheese ripen. Mould-ripened cheeses ripen much faster than hard cheeses. They take weeks instead of months or years. This is because the fungi used are very active compared to the starter bacteria.

Some cheeses, like Camembert and Brie, ripen on the surface. Others, like Stilton, ripen inside. Stilton cheese is poked with stainless steel wires. This lets air inside, which helps the mould spores grow, like Penicillium roqueforti. Some cheeses, like Saint-Nectaire, also have yeasts growing on their surface. These yeasts add flavor and change the texture of the cheese's coat. Other cheeses develop special bacterial growths on their surface, which give them unique colors and looks. For example, Brevibacterium linens gives some cheeses an orange coat.

| Emma Amos |

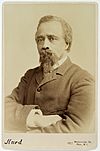

| Edward Mitchell Bannister |

| Larry D. Alexander |

| Ernie Barnes |