Cork (material) facts for kids

Cork is a special material that comes from the bark of a tree called the Cork Oak. It's mostly used to make stoppers for wine bottles, but it has many other cool uses too! Portugal makes about half of all the cork in the world.

The cork industry is very good for the environment. This is because you don't cut down the tree to get the cork. Instead, you just carefully peel off its bark. The tree keeps living and growing, which is super sustainable! Cork products are also easy to recycle.

Cork is in high demand, especially for sealing wine bottles. While top-quality corks can be pricey, some cheaper wines use different kinds of stoppers. These might be made from plastic, screwcaps, or other materials.

Contents

Where Does Cork Come From?

There are huge forests of cork trees around the world, covering about 2.2 million hectares. A big part of these forests, about 34%, is in Portugal. Another 27% is in Spain.

Every year, about 200,000 tons of cork are produced. Portugal leads the way, making almost half of it (49.6%). Spain is next with 30.5%. Other countries like Morocco, Algeria, Tunisia, Italy, and France also produce cork.

Cork trees can live for a very long time, sometimes up to 300 years! Once a tree is about 25 years old, its bark can be harvested. This happens every nine years. The first few harvests usually produce lower quality cork.

How is Cork Harvested?

Harvesting cork is a very careful process. It only happens from early May to late August. This is when the cork can be removed without hurting the tree. When a cork tree is about 25 to 30 years old, and its trunk is about 60 cm (24 inches) around, the first cork can be taken off. However, this first cork is usually not the best quality. It can be used for things like flooring, shoes, or insulation.

The people who remove the cork are called extractors. They use a very sharp axe. They make two main types of cuts:

- A horizontal cut around the tree, like a "necklace."

- Several vertical cuts, called "rulers" or "openings."

This part of the job is very delicate. The extractor needs to be strong but also very precise. They must not damage the inner layer of the bark, called the phellogen. If they do, the tree could be harmed.

To get the cork off, the extractor pushes the axe handle into the vertical cuts. A good extractor can remove a large piece of cork without damaging it or the tree. These large pieces of cork are called "planks."

Cork forests are often hard for vehicles to reach. So, the planks are usually carried out by hand. They are then stacked in piles to dry. After drying, they can be loaded onto trucks and sent to a factory for processing.

Amazing Uses for Cork

Cork is amazing because it's both stretchy and almost waterproof. This makes it perfect for many different products.

Cork's unique structure, full of tiny air bubbles, also makes it great for insulating homes. It helps keep houses warm in winter and cool in summer. It's also naturally good at resisting fire. Corkboard, which is made from leftover cork pieces, is a popular choice for insulation. It's safe, easy to use, and doesn't cause allergies.

Sheets of cork, also often made from leftover pieces, are used for bulletin boards. You can also find cork tiles for floors and walls.

Because cork is so light, it's used for fishing floats and buoys. It's also used for handles on fishing rods.

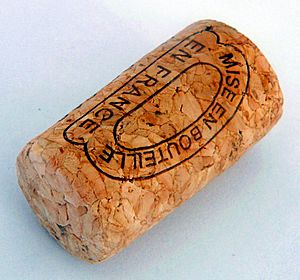

Cork in Wine Bottles

Long ago, in the mid-1600s, French winemakers didn't use cork stoppers. They used oil-soaked rags to seal their bottles!

Today, most wine bottles use cork stoppers. These can be made from a single piece of cork or from many small cork particles pressed together. The ones made from particles are called "agglomerated corks," like those used for champagne.

Cork is great for wine bottles because it can be squeezed tightly when put into the bottle. Then, it expands to create a very tight seal. This keeps the wine fresh.

Studies have shown that cork stoppers are the most environmentally friendly choice compared to plastic stoppers or metal screw caps.

Other Cool Uses

Cork is used in many other interesting ways:

- In woodwind instruments, like clarinets, to make sure the parts fit together tightly and no air leaks out.

- For handles on some conducting batons.

- In shoes, especially in the soles.

- To make bricks for house walls, like the special pavilion at Expo 2000 in Portugal.

- The Portuguese postal service even made the world's first postage stamp out of cork in 2007!

- It's the core of baseballs and cricket balls.

- In spacecraft heat shields and fairings to protect them from extreme heat.

- In inkjet and laser printers for picking up paper.

- Inside footwear for comfort and to help with temperature control.

- To make later models of pith helmets.

- Some people hang corks from their hats to keep insects away!

- As a core material in strong, lightweight "sandwich composite" structures.

- In some mopeds for the automatic transmission clutch.

- For parts of car interiors instead of wood or aluminum.

- To make watch bands and faces, like with Sprout Watches.

- Orchid growers sometimes use cork slabs as a natural way to mount their plants.

Images for kids

-

This famous drawing from 1665 by Robert Hooke shows cork under an early microscope.

See also

In Spanish: Corcho para niños

In Spanish: Corcho para niños