Glass facts for kids

Glass is a hard material that can be shaped in many ways. It is usually clear, so you can see through it, but it can also be made in different colours. Glass is mostly made from silica, which is a type of sand.

The glass used for windows and bottles is called soda-lime glass. It's made of about 75% silica, along with sodium oxide (from soda ash) and calcium oxide (also known as lime). Small amounts of other things are added too.

By changing how much of each ingredient is used, or by adding new ones, many different kinds of glass can be made. For example, coloured glass gets its colour from tiny amounts of metal oxides. Just a little bit of cobalt oxide can make glass blue!

Crystal glass is made by adding lead and zinc oxides. Even though it's called "crystal," glass is not actually a true crystal. This is because glass is a non-crystalline solid, meaning its atoms are not arranged in a perfect, repeating pattern. If crystal glass has been decorated by hand using spinning wheels, it's called cut glass. This means a worker carefully holds the glass against different sized wheels to create patterns.

Because glass is used to make lenses, the word "glasses" also means eyeglasses.

There's a common story that glass is actually a very slow-moving liquid. This idea came from old windows in houses and churches, some 200 to 300 years old, which sometimes look a bit wavy or thicker at the bottom. However, this is not because the glass has slowly flowed downwards. It's actually because of how glass was made in the past. Back then, glass panes were often thicker on one edge than the other. Builders would usually install them with the thicker edge at the bottom for stability.

Glass is great because it can be recycled again and again! Glass bottles and jars can easily be turned into new ones. They can also be used in building materials or as a type of sand.

-

Roman glass beaker from the 4th century A.D.

-

A glass with water.

-

Stained glass windows in a Christian church.

Contents

How Glass Works and What It's Made Of

Seeing Through Glass

Glass is used everywhere because we can make it clear, allowing us to see through it. Unlike many other materials that scatter light, glass lets light pass right through. This is because glass doesn't have tiny internal boundaries that would reflect or scatter light. Also, the surface of glass is usually very smooth. This smoothness helps keep glass clear, even if it's coloured.

Glass can bend, reflect, and let light pass through it without scattering. This is why it's perfect for making lenses and windows. Regular glass bends light by a certain amount, which scientists call its refraction index. This property is also why glass is used in optoelectronics, like in optical fibers that carry light signals.

Other Cool Features of Glass

When glass is being made, it can be poured, shaped, or moulded into many different forms. These can range from flat sheets to very detailed objects. Once finished, glass is usually brittle, meaning it can break easily unless it's specially treated or layered. However, it's also very strong and lasts a long time in most conditions. It doesn't wear away easily and can handle water and many chemicals. This makes it a great material for food containers and chemical bottles.

Making Glass Today

To make glass, raw materials are first mixed together. Then, they are heated in a furnace until they melt. For making lots of glass, like soda-lime glass for windows, large furnaces powered by gas are used. Smaller furnaces are used for special types of glass.

After the glass melts and any bubbles are removed, it is shaped. Flat glass for windows is made using a method called the float glass process. This process was invented in the 1950s by Sir Alastair Pilkington in the UK. In this method, molten glass floats on a bath of melted tin. This makes a perfectly flat and smooth sheet of glass.

Glass for bottles and jars is shaped by blowing and pressing methods. Once the glass has its desired shape, it is usually slowly cooled down in a process called annealing. This helps remove any stress in the glass, making it stronger.

Sometimes, glass is given special treatments or coatings. These can make it more resistant to chemicals, stronger (like toughened glass or bulletproof glass for car windshields), or improve its optical properties (like insulated glazing for better insulation).

Adding Colour to Glass

Glass gets its colour from tiny, electrically charged particles called ions, or from very small particles mixed into it.

Regular soda-lime glass looks clear when it's thin. But if you look at a thick piece, you might see a slight green tint. This green colour comes from small amounts of iron(II) oxide (FeO) impurities. More FeO and Cr2O3 can be added to make green bottles.

To make amber glass, which ranges from yellowish to almost black, Sulfur, carbon, and iron salts are used. A glass melt can also turn amber if it's heated in a certain way. Manganese dioxide can be added in small amounts to get rid of the green tint caused by iron.

For art glass or studio glass, special recipes are used to create specific colours. These recipes involve mixing different metal oxides, melting the glass at certain temperatures, and heating it for specific times. Most coloured glass for art is made in large amounts by companies that sell to artists. However, some glassmakers can create their own colours from raw materials.

The Story of Glass Through Time

The word glass came about in the late Roman Empire. It likely came from a Germanic word meaning a clear, shiny material.

Naturally occurring glass, like obsidian (volcanic glass), was used by many ancient societies. They used it to make sharp cutting tools. Because obsidian was only found in certain places, it was traded widely. However, the first true glass made by people probably came from coastal north Syria, Mesopotamia, or Ancient Egypt. The oldest known glass objects, from around 2500 BCE, were beads. These might have been made by accident while working with metals or making Egyptian faience, which is a material similar to glass.

Glass was a very special and expensive material for a long time. When many ancient civilizations collapsed around the end of the Bronze Age, glass-making also stopped for a while. In South Asia, people might have started making glass around 1730 BCE. However, in ancient China, glassmaking started much later compared to pottery and metalwork. In the Roman Empire, glass objects have been found everywhere, in homes, workshops, and burial sites.

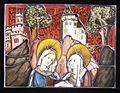

Glass was used a lot during the Middle Ages. In England, during the Anglo-Saxon period, glass was used for things like cups, beads, windows, and even in jewellery. From the 10th century onwards, glass became very important for stained glass windows in churches and cathedrals. Famous examples can be seen at Chartres Cathedral and the Basilica of St Denis. By the 14th century, architects were even designing buildings with walls made almost entirely of stained glass, like Sainte-Chapelle in Paris. Stained glass became popular again in the 19th century with Gothic Revival architecture.

During the Renaissance, building styles changed, and large stained glass windows became less common. However, the use of glass in homes grew. At first, windows had small panes of glass held together with lead. But as technology improved, glass could be made more cheaply in larger sheets. This led to bigger window panes and, in the 20th century, much larger windows in homes and businesses.

In the 20th century, new types of glass like laminated glass (layered glass), reinforced glass, and glass bricks made glass even more useful in building. Many tall buildings today have outer walls almost entirely made of glass. Laminated glass is also widely used for car windscreens. While glass containers have always been used for storage because they are clean and safe, glass has been used more and more in different industries.

Optical glass for eyeglasses has been used since the late Middle Ages. Making lenses has become much better over time, helping astronomers explore space and having many uses in medicine and science.

From the 19th century, many old glass-making techniques were brought back, including Cameo glass. This technique, where layers of glass are carved to create a raised design, was achieved again for the first time since the Roman Empire. The Art Nouveau movement used glass a lot. Artists like René Lalique, Émile Gallé, and Daum of Nancy made colourful vases and other pieces, often using cameo glass and shiny finishes. Louis Comfort Tiffany in America was famous for his stained glass, both for churches and homes, and his well-known lamps. In the early 20th century, large factories like Waterfords and Lalique started making glass art. Since about 1960, many small studios have started making glass artworks by hand. Glass artists now see themselves as sculptors working with glass, and their creations are considered fine arts.

-

Mouth-blown window-glass in Sweden at Kosta Glasbruk, (1742). It has a mark from the glassblower's pipe.

-

Windows in the choir of the Basilica of Saint Denis, one of the earliest uses of large glass areas. These windows are from the 19th century.

Images for kids

-

Quartz sand (silica) is the main material used to make commercial glass.

-

A Pyrex borosilicate glass measuring jug.

-

A CD-RW (CD). Chalcogenide glass is used in rewritable CDs and DVDs.

-

Part of a German stained glass panel from 1444. It uses different coloured glass, paint, and silver stain.

-

A piece of volcanic obsidian glass.

-

Tube fulgurites, which are natural glass tubes formed by lightning striking sand.

-

Trinitite, a glass made by the Trinity nuclear-weapon test.

-

Iron(II) oxide and chromium(III) oxide are often added to make green bottles.

-

Cobalt oxide makes rich, deep blue glass, like Bristol blue glass.

-

Different additives create different colours in glass: turquoise (Copper(II) oxide), purple (Manganese dioxide), and red (Cadmium sulfide).

-

Cut lead crystal glass.

-

A glass decanter and stopper.

-

A Vigreux column in a laboratory setup.

-

Graduated cylinders, used for measuring liquids.

-

Erlenmeyer flask, a common lab tool.

-

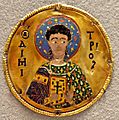

Byzantine cloisonné enamel plaque of St Demetrios, around 1100, using a special "sunk" technique.

-

The Reichsadlerhumpen, an enamelled glass beaker with the double-headed eagle of the Holy Roman Empire, popular from the 16th century.

-

Émile Gallé, Marquetry glass vase with clematis flowers (1890-1900).

-

Glass vase by art nouveau artist René Lalique.

-

Clara Driscoll Tiffany lamp, laburnum pattern, around 1910.

See also

In Spanish: Vidrio para niños

In Spanish: Vidrio para niños

| Georgia Louise Harris Brown |

| Julian Abele |

| Norma Merrick Sklarek |

| William Sidney Pittman |