Ironworks facts for kids

An ironworks is a large factory where iron is made and shaped into heavy products. It's also where steel products are often created. The word "ironworks" can mean one factory or many factories.

Long ago, ironworks replaced older, simpler ways of making iron, like using bloomeries. This happened when blast furnaces were invented. In the 1800s, a typical ironworks had blast furnaces and other special furnaces or a foundry.

Later, new methods like the Bessemer process were developed. These new ways made steel more easily. Because of this, many places that used to be called ironworks started to be called steelworks instead.

Sometimes, you might hear the word siderurgy to describe the work done at an ironworks. This word comes from Greek words meaning "iron" and "work." It's not a common English word, but it's used in some other languages.

Historically, many towns grew up around ironworks. The people living there depended on the ironworks for jobs and homes. When an ironworks closed down, these towns often faced tough times.

Contents

How Ironworks Make Metal

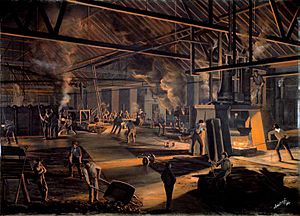

Ironworks use different processes to make iron and steel. Here are some of the main ways:

- Blast Furnaces: These tall furnaces make pig iron from iron ore. Pig iron is a basic form of iron that needs more processing.

- Bloomeries: These were older, simpler furnaces. They made wrought iron directly from iron ore.

- Finery Forges: These places turned pig iron into wrought iron. They used charcoal as fuel.

- Foundries: In a foundry, pig iron is melted again. It's then poured into molds to create cast iron products.

- Puddling Furnaces: This was a later method to make wrought iron from pig iron. It used coke as fuel. After puddling, the iron was shaped into bar iron using a rolling mill.

Making Modern Steel

From the 1850s onwards, new methods were developed to turn pig iron into mild steel. These processes include:

- The Bessemer process: This method uses a special container called a Bessemer converter to remove impurities from iron.

- The Siemens-Martin process: This process uses an Open hearth furnace to make steel.

- Electric Arc Furnaces: These furnaces use electricity to melt metal. They were first used in 1907.

- Basic Oxygen Steelmaking: This modern method, introduced in 1952, uses oxygen to refine iron into steel.

Factories that use these modern methods are usually called steelworks because they focus on making steel.

Shaping and Finishing Metal

After making the basic iron or steel, it often goes through more steps to become useful products:

- Slitting Mills: These machines cut flat bars of iron into rods. These rods were then used to make nails.

- Tinplate Works: Here, rolling mills made thin sheets of iron or steel. These sheets were then coated with tin.

- Plating Forges: These places used a special hammer called a tilt hammer to make thinner iron. This thinner iron was used for things like knives and other cutlery.

Most of these processes didn't make finished products right away. Often, skilled workers like blacksmiths would then shape the metal by hand. Iron and steel were also very important for building things like ships.

Famous Ironworks Around the World

Many important ironworks have existed throughout history and continue to operate today. Here are a few examples from different parts of the world:

Africa

South Africa

- Cape Town Iron and Steel Works in Kuilsrivier

- Mittal Steel South Africa

Americas

United States

- Saugus Iron Works in Saugus, Massachusetts: This was one of the earliest ironworks in North America.

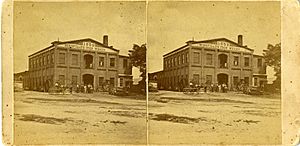

- Tredegar Iron Works in Richmond, Virginia: This ironworks played a big role during the American Civil War.

- U.S. Steel: A very large steel company with many important plants, like Gary Works near Chicago.

Asia

China

- China Baowu Steel Group: One of the world's largest steel producers, with many sites like Baosteel in Shanghai.

- Shougang Group in Beijing.

India

- Steel Authority of India, Ltd (SAIL) has five major steel works.

- Tata Steel in Kalinganagar.

Japan

- JFE Steel has major works like the Chiba Works.

- Nippon Steel & Sumitomo Metal operates large plants such as the Kimitsu Steel Works.

Korea

- POSCO: A leading global steel company with large steelworks in Pohang and Gwangyang.

- Hyundai Steel in Incheon.

Europe

Czech Republic

- Třinec Iron and Steel Works in Třinec.

Germany

- Völklingen Ironworks Heritage Site: This is a UNESCO World Heritage site, showing how iron was made in the past.

Great Britain

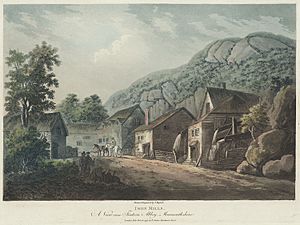

- Blaenavon Ironworks Heritage Site in South Wales: Another important historical site.

- Coalbrookdale Ironworks: Famous for its role in the Industrial Revolution.

Italy

- Acciaieria di Taranto: One of the biggest integrated steel mills in Europe.

Sweden

- Engelsberg Ironworks in Ängelsberg: A well-preserved historical ironworks and a UNESCO World Heritage site.

Russia

- Magnitogorsk Iron and Steel Works: A very large iron and steel plant.

- Severstal in Cherepovets.

Spain

|