William Fairbairn facts for kids

Quick facts for kids

Sir William Fairbairn

|

|

|---|---|

by Benjamin Rawlinson Faulkner, in the foreground Observations of the Cold blast, referring to On the strength and properties of cast iron obtained from the Hot and Cold blast, presented at the British Association for the Advancement of Science in 1838

|

|

| Born | 19 February 1789 Kelso, Scotland

|

| Died | 18 August 1874 (aged 85) Moor Park, Farnham, England

|

| Nationality | British |

| Known for | Structural ironwork Shipbuilding Locomotives Lancashire Boiler |

Sir William Fairbairn (born February 19, 1789 – died August 18, 1874) was a very important Scottish engineer. He was a civil engineer, which means he designed big structures like bridges and buildings. He was also a structural engineer and a shipbuilder. In 1854, he became the third president of the Institution of Mechanical Engineers, following famous engineers George Stephenson and Robert Stephenson.

Contents

Becoming an Engineer

William Fairbairn was born in Kelso, Scotland. His father was a farmer. From a young age, William showed a talent for machines. He became an apprentice (a trainee) millwright in Newcastle upon Tyne. This is where he met George Stephenson, who would later become a famous railway engineer.

In 1813, Fairbairn moved to Manchester. He worked for other engineers before starting his own business in 1817. He teamed up with James Lillie to create Fairbairn and Lillie Engine Makers. They built machinery for mills.

Designing Strong Structures

Fairbairn loved to learn new things. In 1830, he joined the Institution of Civil Engineers.

Improving Iron Beams

In the 1820s and 1830s, Fairbairn and another engineer, Eaton Hodgkinson, studied how to make the best iron beams. They wanted to find the strongest shape for these beams. For example, they designed a bridge over Water Street for the Liverpool and Manchester Railway. This bridge opened in 1830.

Building Tube Bridges

In the 1840s, Robert Stephenson (George Stephenson's son) needed to build a bridge across the Menai Strait in Wales. He asked Fairbairn and Hodgkinson for help. Fairbairn came up with the idea of a rectangular tube, like a big box, to bridge the wide gap. This was called a box girder.

Fairbairn did many tests on small models of these tubes. He showed how to build them to be strong. The first bridge using this design was the Conway bridge. After that, the much larger Britannia Bridge was built using the same idea. However, these tube bridges were very expensive because they needed a lot of wrought iron. Fairbairn later created trough bridges, which were also made of wrought iron and used some of his tube bridge ideas.

Building Ships

When the cotton industry slowed down, Fairbairn started making other things. He began building boilers for locomotives and also got into shipbuilding. He thought of a ship as a floating tube. He even criticized the old rules for ship design.

Iron Ships on the Thames

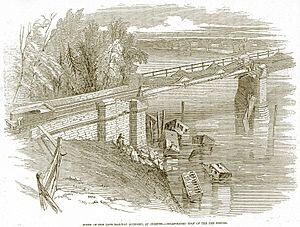

In 1830, Fairbairn and Lillie built their first iron paddle-steamer, the Lord Dundas, in Manchester. Building iron ships so far from the sea was hard. So, in 1834–35, they moved their shipbuilding business to Millwall, London.

At Millwall, Fairbairn built over eighty ships. These included large ships like the Pottinger for the Peninsular and Oriental Company. He also built ships for the British Government. Fairbairn helped introduce iron shipbuilding to the River Thames. He stopped this part of his business in 1848. His experience with iron ships helped him design the Britannia Bridge and Conwy Railway Bridges.

Making Railway Locomotives

Fairbairn started building railway locomotives in 1839. His first design was an 0-4-0 type for the Manchester and Bolton Railway. By 1862, his company had built more than 400 locomotives. These were for companies like the Great Western Railway and the London and North Western Railway. Because his factory didn't have direct rail access, all the locomotives had to be moved by road.

Boiler Innovations

Fairbairn created the Lancashire boiler in 1844. This was an important step in boiler design.

Studying Metal Fatigue

In 1861, the UK Parliament asked him to study how metals break down over time. He did early research into metal fatigue. He showed that if you repeatedly put weight on a metal, it can break even if the weight is not very heavy. For example, he raised and lowered a 3 tonne weight onto a wrought iron cylinder 3 million times until it broke. He found that a steady weight of 12 tonnes was needed to break it in one go. This showed that repeated stress can cause metal to fracture.

He also experimented with glass cylinders. He found that the stress around the middle of a cylinder (called hoop stress) was twice the stress along its length. This meant that cylindrical boilers usually broke along their length because of this higher hoop stress.

New Boiler Designs

Knowing about hoop stress and how it changed with the size of the boiler led Fairbairn to invent new boiler designs. He created the Fairbairn-Beeley and his five-tube boilers. Instead of one large boiler shell, he used several smaller ones. These smaller shells had less stress on them. This idea eventually led to the use of water-tube boilers, which have many small tubes and are used for high pressures today.

Investigating Failures

Fairbairn was one of the first engineers to carefully study why structures failed. He investigated collapsing textile mills and boiler explosions.

Mill and Bridge Collapses

His report on a mill collapse in Oldham showed that architects sometimes used poor designs for cast iron girders. These girders were meant to support heavy floors. In another report, he warned against using certain types of cast iron girders. He advised Robert Stephenson not to use them in a bridge being built over the River Dee in Chester in 1846. Sadly, that bridge collapsed in May 1847, killing 5 train passengers. This Dee Bridge disaster made people worry about other railway bridges.

Understanding Material Stress

Fairbairn did some of the first serious studies on how repeated weight affects wrought and cast iron girders. He showed that cracks could grow from tiny flaws, leading to a break. This problem is now known as fatigue. He built large machines to test this, with some funding from the Board of Trade.

He also tested glass cylinders under pressure. He proved that the highest stress in the wall happens around the diameter. This is the hoop stress, and it's twice the stress along the length of the cylinder. His work helped engineers understand why steam boilers and pipes sometimes failed. In 1854, he started the Manchester Steam Users' Association. This group quickly became known for setting national standards for high-pressure steam boilers.

Honours and Recognition

Sir William Fairbairn received many awards and honours for his important work:

- He became a Fellow of the Royal Society in 1850 and won their Gold Medal in 1860.

- He was President of the Institution of Mechanical Engineers from 1854 to 1855.

- He was President of the Manchester Literary and Philosophical Society from 1855 to 1859.

- In 1860, he was elected to the Smeatonian Society of Civil Engineers.

- He was made a Baronet (a special title) in 1869. He had turned down a knighthood in 1861.

- A statue of him stands in Manchester Town Hall.

- He was made an Honorary Member of the Institution of Engineers and Shipbuilders in Scotland in 1859.

- He was President of the British Association in 1861.

- He became a Foreign Honorary Member of the American Academy of Arts and Sciences in 1862.

- In 2017, he was added to the Scottish Engineering Hall of Fame.

Fairbairn is buried in the churchyard of St Mary's Church, Prestwich. Many people, estimated between 50,000 and 70,000, attended his funeral.

Images for kids

| Leon Lynch |

| Milton P. Webster |

| Ferdinand Smith |