Copper wire and cable facts for kids

Copper has been a super important material for electric wiring since the 1820s. That's when the electromagnet and the telegraph were invented. Later, in 1876, the telephone came along, making copper wire even more popular for carrying electricity.

Today, copper is used in many different types of electrical wiring. You'll find copper wire in places where power is made, sent across long distances, and delivered to homes and businesses. It's also key for phones and internet, electronics, and tons of electrical equipment. Even the tiny parts that make electrical connections often use copper.

The biggest use for copper is in Electrical wiring inside buildings. About half of all the copper dug up from the ground is used to make electrical wires and cables!

Contents

Why Copper is Great for Wiring

Super Good at Carrying Electricity

Electrical conductivity tells us how well a material can move electric charge. This is super important for electrical wires. Copper is the best at carrying electricity among all common metals that aren't precious metals like gold or silver.

In a copper atom, there are lots of electrons that can easily move around. When you connect a copper wire to an electric field, these electrons quickly move, creating an electric current. This is why copper is so good at its job!

Because it's so good, copper is the standard that other electrical conductors are compared to. Some metals are lighter than copper, but they need to be much thicker to carry the same amount of electricity. This means they might not fit in small spaces.

Silver is the only metal that conducts electricity better than copper. But silver costs a lot of money and isn't very strong. So, it's only used for special things, like plating parts in high-quality coaxial cables used for very fast signals.

Strong and Hard to Break

Tensile strength is how much force a material can handle before it breaks when you pull on it. Think of pulling a rope until it snaps. Copper is much stronger than aluminium, which is another metal sometimes used for wires.

Copper's strength helps it resist stretching, breaking, and getting damaged. This means fewer problems and interruptions in electrical systems. While copper is heavier than aluminum for the same electrical power, its strength is a big plus.

Easy to Stretch into Wire

Ductility is a material's ability to be stretched or pulled into a wire without breaking. This is really important for making wires! Materials that crack easily can't be shaped or drawn into thin wires.

Copper is very ductile, meaning it can be stretched into very thin wires with great accuracy. Only gold and silver are more ductile than copper.

Strong and Flexible at the Same Time

Usually, strong metals are not very flexible. But copper is different! It's both strong and very flexible. This makes it perfect for wiring systems. For example, at connection points, copper can be bent, twisted, and pulled without stretching or breaking.

Resists Sagging and Loosening

Creep is when a material slowly changes shape over time, especially when it's heated and cooled repeatedly. This can cause electrical connections to become loose, which can lead to overheating or even dangerous sparks.

Copper is excellent at resisting creep. This means connections stay tight and secure. Other metals that creep might need regular checks to make sure screws are still tight.

Resists Rust and Damage

Corrosion is when a material breaks down because of chemical reactions, like rust. Copper generally resists corrosion from moisture, humidity, and pollution in the air. Even if some corrosion forms on copper, it can still conduct electricity a bit.

Copper is also less likely to corrode in wet conditions compared to many other common metals.

Doesn't Change Much with Heat

Most materials expand when they get hot and shrink when they cool down. This isn't great for electrical systems. Copper doesn't expand or shrink much with temperature changes compared to other electrical conductors.

Good at Moving Heat Away

Thermal conductivity is how well a material can move heat. In electrical systems, it's important for getting rid of extra heat, especially at connections. Copper is much better at conducting heat than aluminum. This helps keep electrical systems from getting too hot.

Easy to Solder

Soldering is a way to join two or more metals together using heat. Copper is easy to solder, which helps create strong and lasting connections when needed.

Simple to Install

Copper wire is strong, hard, and flexible, making it easy for electricians to work with. It can be installed simply without special tools. Its flexibility makes it easy to connect, and its hardness helps connections stay secure.

Electricians can pull copper wire through tight spaces easily. It can be bent or twisted without breaking. It's also easy to strip and connect, with less risk of nicks or breaks. All these things make copper wire simple to install.

Different Kinds of Copper Wire and Cable

Solid and Stranded Wires

A solid wire is just one single strand of copper metal. It can be bare or covered in insulation. Solid copper wires are often used inside motors and transformers. They are quite stiff and don't bend easily, so they are used in places where they won't be moved often.

Stranded wire is made of many thinner copper wires twisted together. Stranded wire is much more flexible and easier to install than a thick solid wire of the same size. It also lasts longer in places with lots of vibration. Even though it's made of many strands, it carries electricity just as well as a solid wire of the same thickness.

Cables

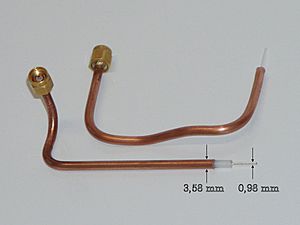

A copper cable is made of two or more copper wires running side by side. They can be bonded, twisted, or braided together. Cables can be made more flexible by using stranded wires inside.

Sometimes, the copper wires in a cable are covered with a thin layer of another metal, usually tin, but sometimes gold or silver. This plating helps prevent oxidation (like rust) and makes soldering easier.

Twisted pair and coaxial cables are special types of cables. They are designed to stop interference from other electrical signals and to make sure signals travel clearly. Shielded cables have an extra layer of foil or wire mesh around them for protection.

Where Copper Wire and Cable are Used

Most electrical wires use a very pure type of copper called Electrolytic-tough pitch (ETP) copper. This copper is great because it conducts electricity very well and is easy to shape. ETP copper is used for sending and distributing power, and for telecommunications. You'll find it in building wires, motor windings, and large electrical bars called busbars.

Special types of copper, like Oxygen-free coppers, are used when wires need to be extra flexible, such as in telecommunications cables.

Here are some of the main places copper wire is used:

Building Wire

Building wire is used to deliver electricity inside homes, offices, and factories. It's also found in mobile homes, RVs, boats, and electrical substations. These wires typically carry voltages up to 600 volts.

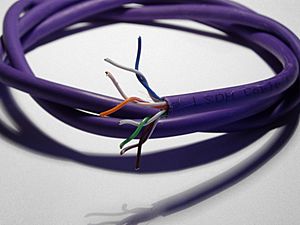

Twisted Pair Cable

Twisted pair cables are very popular for computer networks. They are often used for short and medium connections, up to about 100 meters (328 feet). They are usually cheaper than fiber optic or coaxial cables.

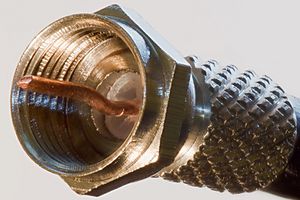

Coaxial Cable

Coaxial cables were once widely used in large computer systems and for early LANs. Today, you'll find them connecting computers to the internet, for video and CATV (cable TV), and for sending radio signals to antennas.

Structured Wiring

Older telephone lines in homes often can't handle modern needs like multiple phone lines, internet, video calls, and security systems all at once. This can lead to problems like static or interrupted service.

Structured wiring is a modern way to set up wiring in homes and buildings for high-speed phone, video, internet, security, and entertainment systems. It usually includes a central box where all connections are made, and special outlets for phones, data, TV, and audio.

Power Distribution

Power distribution is the last step in getting electricity to people who use it. A power distribution system carries electricity from the main power lines to homes and businesses.

Power cables are used to send and distribute electricity, both outdoors and inside buildings. Copper is the top choice for underground power lines that carry very high voltages, up to 400,000 volts. Copper's excellent ability to conduct electricity and heat means these cables can be smaller, lose less power, and stay cooler.

Copper is also widely used in low-voltage lines in mines, underwater, and for electric railroads and cranes.

Appliance Wire

Wires inside home appliances and instruments are made from soft, stranded copper wire. It might be tinned (covered in tin) to make soldering easier. The insulation around the wire depends on how much power it needs to carry.

Automotive Wire and Cable

Wires in cars need special insulation that can handle high temperatures, oil, humidity, fire, and chemicals. Common insulation materials include PVC and neoprene. These wires carry different voltages, from 12 volts for basic electrical systems to up to 15,000 volts for ignition systems.

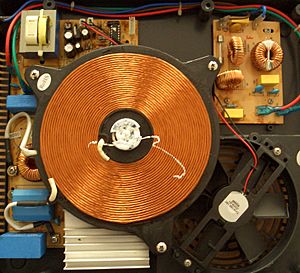

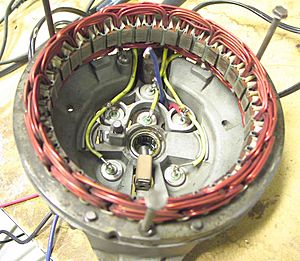

Magnet Wire (Winding Wire)

Magnet wire is a special type of wire used in the coils of electric motors, transformers, generators, headphones, loudspeakers, and electromagnets.

Pure metals like copper and aluminum are best for magnet wire. Copper is usually the first choice because of its excellent chemical, physical, and mechanical properties.

What's Next for Copper Wire?

Copper will likely stay the main material for most electrical wires, especially where space is limited. Car makers, for example, are looking at using thinner wires in some places. They are starting to use copper alloys, like copper-magnesium (CuMg), which allow for smaller, lighter wires that still conduct electricity well. These special alloys are becoming more common in cars, airplanes, and defense equipment.

As we need to send faster internet and phone signals, copper wire's quality is expected to keep getting better. There's a growing demand for copper conductors that are easier to draw into wire and have almost no flaws.

Metal Theft

In the 2000s, the price of copper went up a lot around the world. This unfortunately made some people try to steal copper from power lines and communication cables.

Images for kids

| Janet Taylor Pickett |

| Synthia Saint James |

| Howardena Pindell |

| Faith Ringgold |