Harris tweed facts for kids

Harris tweed (Scottish Gaelic: Clò mór or Clò hearach) is a special type of tweed cloth. It is handwoven by people living in their homes on the Outer Hebrides islands of Scotland. This fabric is also finished on these islands and made from pure, new virgin wool that is dyed and spun there. This unique way of making it, its high quality, and the protection of the Harris tweed name are all set out in a law called the Harris Tweed Act 1993.

Contents

What's in a Name?

The fabric we now call tweed was originally named "tweel". This is the Scots word for twill, which describes how the fabric is woven. There are a few stories about how "tweel" changed to "tweed". One popular story says that in the 1830s, a merchant in London got a letter asking about "tweels" from a company in Hawick. The merchant thought the word was a trade name taken from the River Tweed, which flows through Scotland. After that, the fabric was advertised as "tweed," and the name has been used ever since.

A Rich History

For hundreds of years, people on the islands of Lewis and Harris, the Uists, Benbecula, and Barra have woven cloth by hand. They called it clò-mòr, which means "big cloth" in Scottish Gaelic. At first, these crofters (small farmers) made the cloth for their own use. It was perfect for staying warm in the often cold Scottish weather. The cloth was also used for trading or bartering with others. Sometimes, islanders even paid their rent with blankets or lengths of clò-mòr.

By the late 1700s, making wool yarn from local materials had become a key industry for crofters. The handmade cloth was sent to mainland Scotland and traded, along with other goods like goat and deer skins.

Even as the Industrial Revolution brought machines to Scotland, weavers in the Outer Hebrides kept their traditional hand-weaving methods. The islanders were known for their high-quality handwoven fabrics. However, until the mid-1800s, most of this fabric was made for home use or local trade.

In 1836, Alexander Murray, 6th Earl of Dunmore, took over the North Harris Estate. At this time, all tweed production on the Outer Hebrides was done by hand. Wool was washed in soft, peaty water. Then, it was dyed using colors from local plants and lichens. After that, it was prepared and spun before crofters hand-wove it in their homes.

Traditional island tweed had colorful flecks because of the natural dyes used. One dye came from a lichen called "crottle" (Parmelia saxatilis and Parmelia omphalodes). This gave the fabric deep red, purple-brown, or rusty orange colors. Using these lichens also gave older Harris tweed a unique smell, making it easy to recognize.

When Earl Murray died in 1843, his wife, Lady Catherine Herbert, became responsible for his estate on the Isle of Harris. Lady Catherine saw how special and high-quality the tweed made by two sisters from Strond village was. These sisters, known as the Paisley Sisters, made much better fabric than untrained crofters. In 1846, the Countess asked the sisters to weave tweed with the Murray family tartan pattern. She had this fabric made into jackets for the gamekeepers and ghillies (hunting guides) on her estate. The new clothes were perfect for estate life because they were tough and water-resistant. Her ideas were also helped by "Fanny" Beckett. Fanny organized the weavers, set up training and quality checks, and helped promote Harris tweed as a local and lasting industry.

The Countess started to promote the local fabric as fashionable clothing for hunting and sports. Soon, it became the favorite fabric for wealthy landowners and important people, including those close to Queen Victoria. As demand for this high-quality "Harris tweed" grew, Lady Catherine sent more girls to mainland Scotland for training. She also improved how the yarn was made to create a more consistent fabric. By the late 1840s, shops from Edinburgh to London were selling hand-woven Harris tweed to the rich.

"Fanny" Beckett moved to London in 1888. The "Scottish Home Industries," which managed the new product, became a company in 1896. From then on, the Harris tweed industry grew. It reached its highest production of 7.6 million yards in 1966.

The Harris Tweed Authority

As demand for Harris tweed grew in the early 1900s, many new weavers joined the industry. Some inexperienced weavers started making poorer quality tweed using yarn imported from mainland mills. This led to a less respected name, 'Stornoway tweed'. This lower quality tweed harmed the market for real Harris tweed, which was made by experienced weavers using hand-spun yarn.

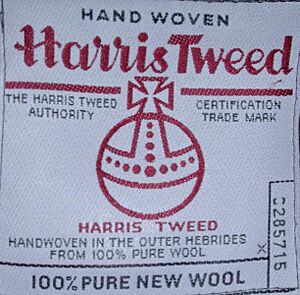

It became very important to legally protect the name Harris tweed with a trademark and a clear definition. Groups of merchants in both Lewis and Harris asked the Board of Trade for a registered trademark. When this trademark, called the Orb, was finally granted, the board insisted it should cover all the islands of the Outer Hebrides. This included Lewis, North and South Uist, Benbecula, and Barra, as well as Harris. The reason was that the tweed was made the same way on all these islands.

In 1909, after many talks, the Orb Trade Mark was granted. The Harris Tweed Association, a group of volunteers, was formed to protect both the Orb Trade Mark and the name ‘Harris tweed’ from fakes.

The first definition for the Orb Trade Mark said that: Harris tweed means a tweed, hand-spun, hand-woven, and dyed by the crofters and cottars (small farmers) in the Outer Hebrides.

In 1993, a new official group, the Harris Tweed Authority, took over from the original Harris Tweed Association. Also in 1993, a law called the Harris Tweed Act 1993 was passed. This law made the Harris Tweed Authority responsible for "promoting and keeping the realness, standard, and good name of Harris tweed." It also stops the sale of material as Harris tweed if it doesn't meet the definition.

The official definition of real Harris tweed became: "Harris tweed means a tweed which has been hand woven by the islanders at their homes in the Outer Hebrides, finished in the islands of Harris, Lewis, North Uist, Benbecula, South Uist and Barra and their surrounding areas (The Outer Hebrides) and made from pure virgin wool dyed and spun in the Outer Hebrides."

Today, an inspector from the Harris Tweed Authority checks every 50 meters of Harris tweed. Then, it is stamped by hand with the Orb Mark. The Harris Tweed Authority is the legal group that makes sure Harris tweed is made correctly. They are involved in legal cases, giving out the Orb Stamp, checking mills and weavers' sheds, promoting the industry, and protecting Harris tweed for the islanders. The Authority is based in Stornoway, the island capital. It has a chief executive, a secretary, two inspectors and stampers, an unpaid board, and a legal team.

Harris Tweed Mills

There are three mills working on the islands today. Each mill has a company that handles marketing, sales, customer service, and sending Harris tweed to buyers. The mills themselves handle parts of the production process.

- The Kenneth Mackenzie Ltd mill in Stornoway is the oldest current producer in the Outer Hebrides. It has been making Harris tweed since 1906. Since 2019, Alexander Lockerby, who used to manage the mill, has owned it.

- The Carloway Mill is an independent producer of Harris tweed in the village of Carloway. It is the smallest of the three Harris Tweed textile mills. It uses traditional machines to make unique and custom Harris tweed cloth.

- Harris Tweed Hebrides reopened a mill in Shawbost in November 2007. The main owner of the company is Ian Taylor, a Scottish businessman.

The Weavers

All weavers work for themselves. They can be 'mill weavers' who are hired by any of the three mills. Or, they can be 'independent weavers' who make and sell their own cloth, sometimes for special orders. Mill weavers get their yarn and instructions from the mills. Once they weave the tweed, the mill collects it for finishing and stamping. Then, the mill sells it.

Independent weavers buy yarn from the mills and prepare it themselves, often creating their own designs. The independent weaver then sends their woven cloth to the mill for finishing and stamping (which they pay for). After that, the cloth is returned to the weaver to sell. A weaver can work as both a mill weaver and an independent weaver.

The Harris Tweed Industry Liaison Group meets regularly to talk about issues facing the industry. This group includes mill owners, weaver representatives, Harris Tweed Authority officials, funding groups, local council members, buyers, and other industry figures.

How Harris Tweed is Made

Making Harris tweed starts with pure, new wool from Cheviot and Scottish Blackface sheep. Most of this wool comes from mainland UK. But in early summer, island communities still gather and shear local sheep to add their wool to the mix. The two types of wool are mixed to get the best qualities from each.

After being shorn, the wool is cleaned (scoured). Then, it is sent in large bales to the mills. There, it is dyed in many different colors for blending.

The freshly dyed colored and white wools are weighed in exact amounts. Then, they are carefully blended by hand to create the correct shade. Next, the wool is carded using machines with teeth. These machines tease and mix the fibers well before separating them into a delicate, new yarn. This soft yarn is then twisted as it is spun. This twisting gives it the most strength for weaving. The spun yarn is wound onto bobbins. These bobbins hold the threads for the weft (left-to-right threads) and warp (vertical threads) that go to the weavers.

In a very important step, thousands of warp threads are gathered in long bundles in a very specific order. They are then wound onto large beams. These beams, along with the weft yarn, are delivered to the weavers.

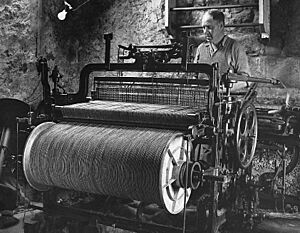

All Harris tweed is handwoven on a foot-powered loom in each weaver's home. Mill weavers use a 'double-width' Bonas-Griffith rapier loom. Independent weavers usually use an older 'single width' Hattersley loom. The weaver will 'tie in' their warp by threading each yarn end through the small holes of their loom's heddles in a certain order. Then, they begin to weave, fixing any mistakes or broken threads until the cloth is finished.

The tweed then returns to the mill in its 'greasy state' (before cleaning). Here, people called darners fix any flaws.

Once ready, the cloth is finished. Dirt, oil, and other impurities are removed by washing and beating the fabric in soda and soapy water. After that, it is dried, steamed, pressed, and trimmed.

The final step is an inspection by the independent Harris Tweed Authority. They visit the mills weekly. After inspection, their Orb Mark trademark is ironed onto the fabric. This mark is a seal of authenticity, proving it's real Harris tweed.

Harris Tweed Today

In 2012, the weavers and mills of the Harris tweed industry made one million meters of Harris tweed. This was a big jump from 450,000 meters in 2009 and the highest production in 17 years. For the past few years, Harris tweed has remained "on-trend." It is often seen in both High Street stores and on fashion show catwalks. Its growing popularity has led to training a new generation of weavers to meet the demand.

Menswear brands like Tommy Bahama, Topman, Brooks Brothers, Nordstrom, Thomas Pink, J. Crew, Hugo Boss, and Paul Smith use the fabric for jackets, outerwear, and suiting.

Footwear brands have also used Harris tweed, including Nike, Dr Martens, and Clarks. The luxury home decor market is also growing. For example, over 90,000 meters of Harris tweed were used in Glasgow's 5-star Blythswood Square Hotel in 2008.

New markets are appearing in countries like Brazil, Russia, India, and China (the BRIC nations). More traditional markets in the USA and Europe are also growing again, as are countries in East Asia, like South Korea. Sales predictions for the cloth are looking good.

See also

In Spanish: Harris Tweed para niños

In Spanish: Harris Tweed para niños

| Kyle Baker |

| Joseph Yoakum |

| Laura Wheeler Waring |

| Henry Ossawa Tanner |