Papermaking facts for kids

Papermaking is how we create paper and cardboard. These materials are super important for writing, printing, packaging, and many other things. Today, most paper is made by huge machines in factories. But making paper by hand is still a special craft, often used for art projects.

To make paper, tiny plant fibers are mixed with a lot of water. This watery mix is then poured onto a screen, like a sieve. The water drains away, leaving a thin mat of tangled fibers. This wet sheet is then pressed to remove more water, sometimes with suction or heat. Once it's dry, you have a flat, strong, and even sheet of paper!

Before big machines were invented, all paper was made by hand, one sheet at a time. People who make paper by hand today still use tools and methods similar to those from hundreds of years ago. These methods first started in China and other parts of Asia, and then changed a bit in Europe. Handmade paper is special because each sheet is unique, unlike the perfectly uniform paper made by machines.

Contents

How Paper Was Invented

The word "paper" comes from "papyrus." This was a thick, paper-like material made from the Cyperus papyrus plant. Ancient Egyptians and other Mediterranean people used papyrus for writing long before paper was made in China.

To make papyrus, thin strips from the inside of the papyrus plant were laid side-by-side. Then, a second layer was placed on top, with the strips going the other way. These two layers were pounded together to form a sheet. Papyrus was strong, but its surface wasn't always smooth. When rolled up and unrolled many times, the strips could come apart.

Paper made from hemp was used in China for wrapping and padding as early as the 8th century BC. We even have paper with Chinese writing on it from 8 BC!

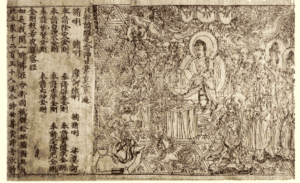

The person usually credited with inventing paper is Cai Lun. He was an official in the Han dynasty (202 BC – 220 CE). Around 105 CE, he supposedly made paper using mulberry tree fibers, other plant fibers, old fishing nets, rags, and hemp waste. By the 3rd century, paper was widely used for writing. By the 6th century, people in China even started using toilet paper! During the Tang dynasty (618–907 CE), paper was folded into square bags to keep tea fresh. Later, the Song dynasty (960–1279 CE) was the first government to print and use paper money.

In the 8th century, papermaking spread to the Islamic world. There, the process was improved, and machines were designed to make paper in larger amounts. Paper production began in cities like Samarkand, Baghdad, Damascus, Cairo, and Morocco, and then in Muslim Spain. In Baghdad, the Grand Vizier Ja'far ibn Yahya oversaw papermaking. Muslims found a way to make thicker paper sheets. This helped turn papermaking from a craft into a big industry.

The first time water-powered mills were used in paper production was in Samarkand in the 8th century. These mills helped prepare the pulp for papermaking. The first mentions of paper mills also come from the medieval Islamic world, noted by Arabic geographers in Damascus in the 9th century.

Traditional papermaking in Asia uses fibers from the inner bark of plants. These fibers are soaked, cooked, rinsed, and then often beaten by hand to create paper pulp. The long fibers create strong, thin sheets of paper. In Eastern Asia, common fibers include abaca, kōzo, and gampi. In the Himalayas, paper is made from the lokta plant. This paper is used for beautiful writing, printing, book art, and even origami.

In Europe, papermakers started using metal wires in their papermaking moulds. This led to features like the watermark, which was common by 1300 CE. Hemp and linen rags were the main source of pulp. Later, cotton became popular after large amounts were grown in Southern plantations. At first, papermaking wasn't very popular in Europe because papyrus and parchment worked well enough. But in the 15th century, when the movable type printing press was invented, there was a huge demand for paper. This led to many paper mills opening, and papermaking became a major industry.

Modern papermaking started in the early 19th century in Europe with the invention of the Fourdrinier machine. This amazing machine makes a continuous roll of paper, not just single sheets. These machines are huge! Some can make paper 150 meters long and 10 meters wide, at speeds up to 100 kilometers per hour. In 1844, Canadian Charles Fenerty and German Friedrich Gottlob Keller invented the process to make paper using wood pulp. This changed everything! It ended the nearly 2,000-year tradition of using pulped rags and started a new era where almost all paper, especially newsprint, was made from wood pulp.

How Paper Is Made by Hand

Making paper, whether by hand or machine, involves mixing fibres with water to create a thin liquid called "furnish." This furnish is then drained through a screen, which leaves behind a mat of tangled fibers. Water is then squeezed out of this fiber mat using a press.

The way paper is made by hand hasn't changed much over time. The process usually has five main steps:

- Getting the useful fibers from raw materials (like cellulose from wood or cotton).

- Beating the fibers into a soft pulp.

- Adding special chemicals to change the paper's color, strength, or other features.

- Using a screen to form the paper sheet from the liquid mix.

- Pressing and drying the sheet to get the final paper.

To screen the fibers, a mesh made of strong, non-rusting material (like brass or stainless steel) is stretched over a "paper mould." This mould is a wooden frame, similar to a window frame. The size of the paper depends on the open area of this frame. The mould is dipped completely into the furnish, then pulled out, shaken, and drained. This creates an even layer of fibers on the screen.

Next, the wet mat of fibers is carefully laid onto a damp cloth or felt. This step is called "couching." This process is repeated for as many sheets as needed. The stack of wet mats is then pressed in a hydraulic press to squeeze out most of the water. Finally, the damp paper is dried using different methods, like vacuum drying or simply air drying. Sometimes, each sheet is rolled to make it flatter, harder, and smoother. Last, the paper is cut to the right size (like A4 or letter size) and packaged.

The wooden frame used in hand papermaking is called a "deckle." The deckle leaves the edges of the paper slightly rough and wavy. These are called "deckle edges," and they are a sign that the paper was made by hand. Sometimes, machines try to copy deckle edges to make new paper look old and fancy.

The lines you might see in handmade paper are from the wires in the screen. The lines that run sideways are called "laid lines." The lines that run usually from top to bottom, made by the wires holding the sideways wires together, are called "chain lines." Watermarks are made by weaving a design into the wires of the mould itself. Handmade paper often folds and tears more easily along the laid lines.

Paper made from other fibers, like cotton, is often considered more valuable than paper made from wood.

How Paper Is Made in Factories

A modern paper factory, or paper mill, has several sections that are similar to the steps in making handmade paper. First, wood pulp is refined and mixed with water and other things to create a liquid pulp slurry. The "head-box" of a paper machine, often a Fourdrinier machine, spreads this slurry onto a long, moving screen. Water drains from the slurry by gravity or with a vacuum. The wet paper sheet then goes through presses and dryers. Finally, it's rolled into huge rolls that can weigh many tons.

Another type of paper machine, invented by John Dickinson in 1809, uses a spinning cylinder mould. This mould rotates while partly dipped in a vat of thin pulp. The pulp sticks to the wire mesh on the mould as it comes out of the vat. A roller then presses against the mould to smooth the pulp and lift the wet sheet off.

Making paper can affect the environment. It uses strong chemicals and a lot of water, which can lead to pollution. Also, cutting down many trees for wood pulp means fewer trees to absorb carbon dioxide, which is important for our planet.

Famous Papermakers

For most of history, papermaking was a very specific job. But the term "notable papermakers" can include more than just those who physically make paper. In handmade paper art, it can mean artists who use paper in special ways. In science, it can mean people who research, teach, or help preserve old books and paper. In the paper industry, it often includes scientists, engineers, and business leaders.

Some famous people known for other things actually had a papermaking background. For example, the Montgolfier brothers, who were the first humans to fly in a hot air balloon, owned a paper mill. Many stories don't mention this, but the paper used in their balloons was very important to their success!

Important inventors in papermaking include James Whatman, Henry Fourdrinier, Heinrich Voelter, and Carl Daniel Ekman.

By the mid-1800s, making paper by hand had almost disappeared in the United States. But in 1912, a fine book printer named Dard Hunter brought the craft back. However, interest faded again by the 1930s. After World War II, artist Douglass Howell returned to New York City and found that art paper was hard to get. In the 1940s and 1950s, Howell studied Hunter's books, learned about hand papermaking history, did his own research, and learned about printed books. He helped revive the craft.

See also

- Amate, paper made from bark, used in ancient Central America

- Bookbinding

- Museums: Williams Paper Museum, Basel Paper Mill

- Stickies (papermaking)