Portland cement facts for kids

Portland cement is the most common type of cement used around the world. It's a key ingredient in things like concrete, mortar (used for bricks), and stucco (a type of plaster). It was first developed in England in the early 1800s by Joseph Aspdin. It's usually made from limestone.

Portland cement is a very fine powder. It's made by heating limestone and clay in a special oven called a kiln. This process creates small, hard lumps called clinker. Then, these clinkers are ground into a powder, and a small amount of gypsum is added. Most portland cement is grey, but you can also find white portland cement. It got its name because it looked like a building stone from Portland, England.

Because the materials used to make portland cement (like limestone and shale) are easy to find and not expensive, portland cement is a fairly cheap building material. Its main use is to make concrete, which is a mix of gravel, sand, cement, and water.

Contents

History of Portland Cement

The idea for portland cement came from earlier types of cement made in Britain in the mid-1700s. It was named "portland cement" because it looked similar to a famous building stone called Portland stone, which comes from the Isle of Portland in England.

The journey to modern portland cement began in 1756. A man named John Smeaton experimented with different limestones to build a lighthouse. Later, in 1796, James Parker developed and patented "Roman cement," which became popular but was later replaced by portland cement.

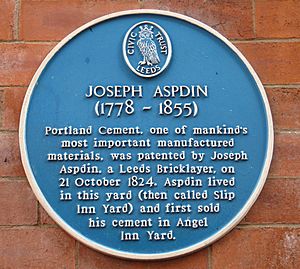

In 1824, Joseph Aspdin got a patent for his invention, which he called "portland cement." His cement was a first step, but it wasn't quite like the modern version we use today.

Joseph Aspdin's son, William Aspdin, continued to work on cement. In the 1840s, he made important improvements, creating what we now consider "modern" portland cement. He accidentally discovered how to make stronger calcium silicates, which are key to portland cement.

In 1859, new standards for cement were set for the London sewer project. This helped define what portland cement should be like. A big step forward in making cement was the invention of the rotary kiln by Frederick Ransome in 1885. This new oven allowed for a stronger, more even mix and a continuous way to make cement.

Portland cement was first brought into the United States from Germany and England. By the 1870s, it started to be made in the U.S. The first portland cement in America was produced in 1875 in Coplay, Pennsylvania. By the early 1900s, American-made portland cement had largely replaced imported cement.

What is Portland Cement Made Of?

Portland cement is mainly made up of special calcium silicates. These are materials that react with water to become hard and strong. It also contains a small amount of calcium sulphate (like gypsum), which helps control how fast the cement sets. There are also other minor ingredients.

The main part of cement is called clinker. Clinkers are small, hard lumps that are made when raw materials are heated to very high temperatures (over 1300°C or 2372°F). At these high temperatures, a chemical reaction happens where different parts combine to form the strong materials found in cement.

The main raw material for making clinker is usually limestone (which is mostly calcium carbonate). This is mixed with other materials like clay or sand, which provide other important ingredients. Sometimes, impure limestone that already contains clay is used. Other materials like shale, iron ore, bauxite, fly ash, and slag can also be used. Even the ash from coal used to heat the kiln can become part of the raw material.

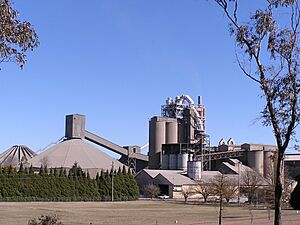

How Portland Cement is Made

Portland cement clinker is made by heating a mix of raw materials in a cement kiln. First, they are heated to about 600°C (1112°F), and then to an even higher temperature, around 1450°C (2642°F), in modern kilns. This intense heat makes the materials stick together and form the clinker lumps.

After the clinker is made, it needs to be ground into a fine powder. This is called cement grinding.

Cement Grinding

To get the cement to set just right, a small amount (usually about 5%) of gypsum is added to the clinker. This mix is then ground into a very fine powder in a special machine called a cement mill. The grinding process is carefully controlled so that the powder has a mix of different particle sizes.

The fineness of the powder is important because it affects how quickly the cement reacts with water. Finer cement usually reacts faster. After grinding, the cement powder is stored in large silos. From there, it's delivered to builders, either in bags or as a bulk powder blown into their storage silos.

| Clinker | What it is | Amount |

|---|---|---|

| Tricalcium silicate | A main part that makes cement strong | 25–50% |

| Dicalcium silicate | Another main part that adds strength | 20–45% |

| Tricalcium aluminate | Helps with early strength | 5–12% |

| Tetracalcium aluminoferrite | Adds to strength and color | 6–12% |

| Gypsum | Controls how fast cement sets | 2–10% |

How Cement Sets and Hardens

When portland cement is mixed with water, it starts a complex series of chemical reactions. These reactions cause the cement to "set" (become stiff) in a few hours and then "harden" (become strong) over several weeks. The different parts of the cement slowly form crystals that interlock, giving the cement its strength.

Gypsum is added to the cement to stop it from setting too quickly. Without gypsum, the cement would harden almost instantly, making it impossible to work with! After the initial setting, keeping the concrete wet or warm can help it get stronger faster.

Uses of Portland Cement

The most common use for portland cement is to make concrete. Concrete is a strong material made from aggregate (like gravel and sand), cement, and water. Concrete can be poured into almost any shape you want. Once it hardens, it becomes a very strong part of a building or structure.

Concrete is used to build many things, like walls, beams, and even street furniture. It can be mixed right at the construction site or brought in as "ready-mixed" concrete from a factory. Portland cement is also used in mortar (for laying bricks), plasters, and grouts (used to fill gaps).

When water is mixed with portland cement, it usually sets in a few hours. It then gets stronger over weeks. A typical concrete mix becomes quite strong in 24 hours and continues to gain strength for months, as long as there is water for the reactions to continue.

Different Types of Portland Cement

There are several types of portland cement, each designed for specific uses. Here are some common ones:

- Type I: This is the most common or general-purpose cement. It's used for most construction projects, especially when the concrete won't be in contact with soil or groundwater.

- Type II: This type offers good resistance to sulphates (certain chemicals in soil or water that can damage concrete). It also gives off less heat when it hardens. It's often used when concrete is in contact with soil or groundwater.

- Type III: This cement gets strong very quickly. It's ground much finer than Type I cement. This makes it useful for projects where you need the concrete to harden fast, like in precast concrete factories where molds need to be reused quickly. It's also used for emergency repairs.

- Type IV: This type is known for giving off very little heat as it hardens. It's used for huge concrete structures, like dams, where too much heat could cause problems. However, it's not made much anymore because other materials can achieve similar results more cheaply.

- Type V: This cement is used when strong resistance to sulphates is needed. It's designed to prevent expansion and damage caused by sulphates in soil or groundwater. Like Type IV, it's less common now due to newer alternatives.

Some types, like Ia, IIa, and IIIa, have an air-entraining agent mixed in. This creates tiny air bubbles in the concrete, which helps it resist damage from freezing temperatures.

White Portland Cement

White Portland cement is just like regular grey portland cement, but it's white! To make it white, the raw materials must be very pure, especially having very little iron. Iron is what gives regular cement its grey color. Making white cement also needs a higher temperature in the kiln. Because of these special requirements, white portland cement is a bit more expensive than the grey kind. It's often used for decorative purposes where the color of the concrete matters.

Safety When Using Cement

Bags of cement usually have safety warnings on them. This is because cement is very alkaline (the opposite of acidic) and can cause severe skin burns if it stays on your skin when wet. The process of cement hardening also creates heat. If you get wet cement on your skin, you should wash it off right away with water.

Dry cement powder can also irritate your eyes or lungs if you breathe it in. It's important to wear safety glasses and a mask when working with cement to protect yourself.

Environmental Effects of Making Cement

Making portland cement can have an impact on the environment. This includes:

- Air pollution: Dust and gases can be released during quarrying (getting the raw materials) and manufacturing.

- Energy use: A lot of fuel is needed to heat the kilns to very high temperatures.

- Carbon dioxide emissions: When limestone is heated, it releases carbon dioxide (CO2), which is a greenhouse gas. Burning fuel also releases CO2. Cement production contributes about 10% of the world's CO2 emissions.

- Land use: Quarrying for raw materials can change the landscape.

To help reduce these impacts, cement plants use equipment to trap dust and gases. They also try to restore quarries to nature after they are no longer used. Scientists are also working on new types of cement that produce less CO2.

Cement Plants and Waste Disposal

Cement kilns get very hot and have a lot of oxygen, which makes them good for processing different types of waste. They can safely destroy many harmful organic chemicals. Also, many waste materials can be burned as fuel in the kilns, which helps reduce the amount of fossil fuels needed.

Some waste materials used in cement kilns include:

- Used car and truck tires

- Waste paints and lubricants

- Meat and bone meal (from slaughterhouses)

- Waste plastics

- Sewage sludge

- Used wooden railroad ties

Cement plants can also use industrial byproducts, which are materials left over from other industries. These include slag (from metal production), fly ash (from power plants), and silica fume (from steel mills). Using these materials helps reduce waste and can make cement production more sustainable.

See also

In Spanish: Cemento Portland para niños

In Spanish: Cemento Portland para niños

- American Concrete Institute

- Calcium silicate hydrate

- Energetically modified cement

- Environmental impact of concrete

- Lime mortar

- Marl

- Portland Cement Association

- Portland, New Zealand

- Portland Cement Works Precinct

- Rosendale cement

| Shirley Ann Jackson |

| Garett Morgan |

| J. Ernest Wilkins Jr. |

| Elijah McCoy |