Ceramic facts for kids

Ceramic is a name for special materials created using heat. The word ceramic comes from the Greek word keramikos, which means "of pottery" or "for pottery". These materials are usually made from non-living things like metals and other elements, joined together very strongly.

For a long time, the most common ceramics were made from clay. These include things like pottery, bricks, and tiles. Cement and glass are also types of ceramics. When ceramic is mixed with metal, it's called a cermet.

The word ceramic can describe something made of ceramic, like a "ceramic plate." It can also refer to the material itself, or the art of making things from ceramic. Learning how to make and use ceramic materials is part of engineering.

Many clay-based ceramics are hard, but they can also have tiny holes (be porous) and break easily (be brittle). Scientists and engineers study ceramics to make them stronger and find new ways to use them.

Contents

What are the main types of ceramic materials?

Ceramic products are often put into four main groups. Here are some examples for each group:

- Structural ceramics: These are used in buildings and construction. Examples include bricks, pipes, floor tiles, and roof tiles.

- Refractories: These materials can handle very high temperatures. They are used for things like the inside lining of kilns (ovens for firing ceramics), parts of steel and glass-making furnaces, and gas fire heaters.

- Whitewares: This group includes everyday items that are often white or light-colored. Think of tableware (plates, cups), wall tiles, decorative art pieces, and bathroom fixtures.

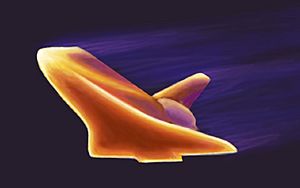

- Technical ceramics: Also called advanced or engineering ceramics, these are very special materials used for high-tech purposes. They include the heat-shielding tiles on the Space Shuttle, bullet-proof vests, parts of jet engines, and even medical implants inside the body. These often don't use clay as a main ingredient.

Common examples of ceramics

- Porcelain: A very strong and often white ceramic.

- 'Hard-paste' porcelain is fired at very high temperatures.

- 'Soft-paste' porcelain, like Bone china, is fired at lower temperatures.

- Earthenware: Often made from clay, quartz, and feldspar. It's usually fired at lower temperatures.

- Stoneware: A type of pottery that is harder and less porous than earthenware.

What are the properties of ceramics?

How strong are ceramics?

Ceramic materials are usually made of tiny crystals that repeat in a pattern, or they can be amorphous (without a repeating pattern). Their parts are held together by very strong chemical bonds. This means they tend to break suddenly (fracture) rather than bending or changing shape permanently like metals do. They are not very tough, meaning they don't resist breaking well.

Also, ceramics often have tiny holes or pores. These holes can make the material even weaker because stress focuses on those small areas. This makes them even more likely to break suddenly.

While ceramics can change shape very slowly under stress, this usually isn't noticeable. Crystalline ceramics are stiff, so deformation happens very slowly. In amorphous ceramics, a slow, thick flow causes deformation.

How do ceramics conduct electricity?

Semiconductors

Some ceramics can act as semiconductors. This means they can conduct electricity under certain conditions, but not as well as metals. A common example is zinc oxide.

Scientists are looking into using semiconducting ceramics for things like gas sensors. When certain gases pass over a ceramic, its electrical resistance changes. This allows us to detect different gases.

Superconductivity

In very cold conditions, some ceramics can become superconductors. This means electricity can flow through them with no resistance at all! Scientists are still trying to fully understand why this happens.

Piezoelectricity, pyroelectricity, and ferroelectricity

- Piezoelectricity is when a material creates an electric charge when you press or squeeze it. Quartz, a ceramic, shows this effect. We use quartz in watches and other electronics to keep time accurately.

- Pyroelectricity is when a material creates electricity when its temperature changes. All pyroelectric materials are also piezoelectric. These materials can turn heat, movement, and electricity into each other. For example, they are used in motion sensors. A tiny change in temperature from someone entering a room can create a voltage that the sensor reads.

- Ferroelectricity is when a material's electric charge can be reversed or moved by an electric field. All ferroelectric materials are also pyroelectric. This property is used to store information in computer memory.

Common piezoelectric ceramics include lead zirconate titanate and barium titanate. They are used in loudspeakers, sonar, and special microscopes.

Insulation at certain temperatures

Some semiconducting ceramics become insulating (stop electricity from flowing) when they reach a certain temperature. This happens at the edges between their tiny grains. We can change this "transition temperature" by altering the ceramic's chemical makeup.

This property is useful for things like self-controlled heating elements, such as in car rear-window defrosters. The ceramic lets current pass through until it reaches the right temperature, then it stops the flow, preventing overheating. These ceramics are also used in capacitors, which store electrical energy.

How are ceramics made?

Ceramics can be divided into two main groups based on how they are made:

Non-crystalline ceramics (Glasses): These ceramics, like glass, are usually made by melting materials and then shaping them. They can be shaped when fully melted (by casting) or when they are thick and sticky like toffee (by blowing into a mold). If these materials are later heated to become partly crystalline, they are called glass-ceramics.

Crystalline ceramics: Making crystalline ceramics is a bit different. They are either made in their final shape through a chemical reaction, or by pressing powders into a shape and then baking them.

Making ceramics in place (In situ manufacturing)

A common example of this method is making cement and concrete. Dry powders are mixed with water, which starts a chemical reaction. This reaction forms long, interlocking crystals that create a solid ceramic.

This method works well for coatings, where different materials are added onto a surface and react to form the ceramic layer. These methods usually create very dense ceramics, but they can be slow.

Making ceramics by baking (Sintering-based methods)

This is a common way to make ceramics. First, a loosely held object (called a "green body") is made from ceramic powder. Then, it's baked in a kiln (a special oven). During baking, the tiny particles in the green body stick together and the object shrinks, becoming denser and stronger. This process is called sintering. The baking happens at a temperature below the ceramic's melting point.

This method is very flexible because the "green body" can be made in many ways. For example, traditional pottery is made by hand-shaping a wet, plastic mixture of clay, then drying and firing it.

Sometimes, the green body is pressed before baking to help it become denser faster. Other times, special organic materials are added to help hold the green body together; these burn away during baking. If a mix of different materials is used, and one melts during baking, it's called liquid phase sintering, which can make the process faster.

Other uses for ceramics

- Ceramic knives: Some kitchen knives have ceramic blades. They stay sharp much longer than steel knives, but they can break if dropped on a hard surface.

- Body armor: Strong ceramics like alumina and boron carbide are used in body armor to stop bullets. Similar materials protect military airplane cockpits because they are light but very strong.

- Ball bearings: Ceramic balls can replace steel ones in ball bearings. They last longer and can spin faster because they are harder and create less friction. They also don't rust, so they can be used in wet places. The main downside is their high cost.

- Engines: In the 1980s, Toyota explored making ceramic engines. These engines could run at extremely high temperatures (over 3300 °C or 6000 °F) without needing a cooling system. This would make cars much lighter and more fuel-efficient. However, it's very hard to make ceramic parts perfectly, and even tiny flaws can cause the engine to break. So, they are not mass-produced yet.

- Jet engine parts: Ceramic parts could also be used in gas turbine engines. This would allow jet engines to run more efficiently, giving planes greater range and carrying capacity for the same amount of fuel.

- Bio-ceramics: These are ceramics used in medicine, like dental implants and artificial bones. Hydroxyapatite, a natural mineral in bone, can be made into ceramic materials. Implants made from these materials can bond well with bone and other body tissues. They are often used to coat metal implants or as bone fillers. Scientists are working to make strong, dense hydroxyapatite ceramics that could one day replace metal and plastic in weight-bearing implants, or even be used to create synthetic bones.

- Watch cases: High-tech ceramics are used for watch cases. They are valued for being light, scratch-resistant, durable, and smooth to the touch.

Images for kids

-

The Meissner effect demonstrated by levitating a magnet above a cuprate superconductor, which is cooled by liquid nitrogen

See also

In Spanish: Cerámica para niños

In Spanish: Cerámica para niños

| Madam C. J. Walker |

| Janet Emerson Bashen |

| Annie Turnbo Malone |

| Maggie L. Walker |