Pottery facts for kids

Pottery is a type of ceramic material used to make many different objects. The main kinds of pottery are earthenware, stoneware, and porcelain. The word "pottery" can also mean the place where these objects are made, or the art of making them. Simply put, pottery is clay that has been baked in a special oven called a kiln.

Pottery objects are made from wet clay mixed with other materials. They are then baked in a very hot oven (a kiln). This baking process makes the clay hard. Sometimes, a potter will add a shiny coating called a glaze to the surface. The object is then baked again. This glaze makes the pottery look nice, and it also makes it waterproof.

Some potters create objects that are not meant to be used, but are instead works of art or sculpture. Pottery without a glaze is called bisque or just earthenware. The best pottery, like porcelain or bone china, is very strong and can even be a little bit see-through.

Contents

History of Pottery

People started making pottery a very long time ago, even before the Neolithic period (when farming began). The oldest pottery we know about is a small statue of a woman called the Venus of Dolní Věstonice. It was found in the Czech Republic and is about 25,000 years old! It might have been used in special rituals.

After people started farming and building cities, they needed containers for food and drinks. That's why pottery has been found at almost every ancient site.

How Pottery is Shaped

Hand-Shaping Methods

Pottery can be shaped in several ways:

- Hand building: This is the oldest way to make pottery. Potters can build objects by rolling out coils of clay, joining flat pieces of clay (slabs), or pinching a ball of clay into a shape. Often, they use a watery clay mixture called slip to stick pieces together. Hand-building is slower than using a wheel, but it gives the potter a lot of control over the size and shape. It's great for making unique art pieces.

- The potter's wheel: This method is called "throwing." A ball of clay is placed in the middle of a spinning table called a wheel-head. The potter spins the wheel using a stick, their foot, or an electric motor. As the wheel spins fast, the potter gently pushes, squeezes, and pulls the soft clay upwards and outwards to create a hollow shape.

The first important step is centering the clay, which means making sure it's perfectly in the middle of the spinning wheel. Then, the potter opens the clay (makes a hole in the middle), floors it (makes the flat bottom inside), and throws or pulls the walls up to an even thickness. Finally, they might trim or turn the pot to remove extra clay and make a neat base.

It takes a lot of practice to throw pots well. This method is best for making round, symmetrical shapes. Potters can then add details by pressing, bulging, carving, or cutting the clay. They can also add handles, lids, or spouts.

Mass-Production Methods

- Granulate pressing: This method shapes pottery by pressing semi-dry, grainy clay into a mold. Water is pumped through a special porous tool to press the clay. This method is often used for making ceramic tiles and plates.

- Injection Moulding: This is like making plastic parts, but for pottery. A mix of clay powder and other materials is injected into a mold. A big advantage is that you can make a cup and its handle all at once, making it stronger. This method is good for making many complex shapes.

- Jiggering and jolleying: These methods use a potter's wheel to make many standard shapes quickly. Jiggering is for flat items like plates. A shaped tool touches the spinning clay on a mold, shaping one side while the mold shapes the other. Jolleying is similar but used for hollow items like cups. These methods have been used since the 1700s and are often automated in factories.

- Roller-head machine: This machine also shapes pottery on a spinning mold, but it uses a spinning tool instead of a fixed one. It can shape items very quickly, about twelve pieces per minute, using less skilled workers. This method became popular after World War II and is still widely used for making flat dishes.

- Pressure casting: This method uses high pressure to force liquid clay (slip) into special molds. This makes the casting much faster than older methods. Also, these molds are very durable and don't need long drying times between uses. Pressure casting was first used for making toilets and sinks, but now it's also used for tableware.

- RAM pressing: This factory process shapes pottery by pressing a slab of prepared clay between two porous mold plates. After pressing, air is blown through the plates to release the shaped item.

- Slipcasting: This is often used for mass production, especially for complex shapes that are hard to make otherwise. A watery clay mixture called slip is poured into a very absorbent plaster mold. The mold soaks up the water, leaving a layer of clay on its inside surface. The extra slip is poured out, the mold is opened, and the shaped object is removed. Slipcasting is common for making sinks and detailed figurines.

Decorating and Glazing

Pottery can be decorated in many ways:

- By carving patterns into the clay itself.

- Using Underglaze decoration (like many blue and white dishes).

- Adding designs in the glaze or on top of the glaze.

- Using enamel (a glassy coating).

Additives can be mixed into the clay before shaping to create different looks. Coarse materials like sand or grog (ground-up fired clay) can give the pottery a certain texture. Different colored clays or grogs can be used to make patterns. Colorants, usually metal oxides, are added to achieve specific colors.

- Agateware: This pottery looks like the stone agate, with swirled bands of color. It's made by blending different colored clays together, but not mixing them completely. This creates a unique swirled or mottled look. Potters need to choose clays that shrink and expand similarly when fired.

- Banding: This is when a band of color is painted by hand or machine around the edge of a plate or cup, often done on a potter's wheel.

- Burnishing: Before firing, the surface of pottery can be burnished by rubbing it with wood, steel, or stone. This creates a shiny, polished finish that lasts after firing.

- Engobe: This is a thin, watery clay mixture used to coat the surface of pottery, usually before firing. It's often for decoration or to hide flaws in the clay underneath. Engobe can be painted or dipped on. Sometimes, a layer of engobe is scratched through to show the color of the clay beneath, a technique called sgraffito.

- Litho: This is short for lithography, also known as a transfer print or "decal." These are designs applied to pottery. A litho has three layers: the colored design, a clear protective layer (sometimes with glass), and a backing paper. The design is transferred onto the pottery, and the backing paper is removed.

- Gold: Gold is used to decorate some high-quality pottery. There are different ways to apply it:

- Best gold: A mixture of gold powder and oils that is painted on. It looks dull after firing and needs to be polished to shine.

- Acid Gold: Developed in England in the 1860s. The glazed surface is etched with acid before the gold is applied. This is a very skilled process used for the finest pottery.

- Bright Gold: This gold shines right after it comes out of the kiln and doesn't need polishing.

- Mussel Gold: An old method made by rubbing gold leaf, sugar, and salt together, then washing away the sugar and salt.

Glazing

Glaze is a glassy coating on pottery. Its main jobs are to decorate the pottery and protect it. A very important use of glaze is to make pottery waterproof so it can hold liquids. Glaze can be applied by dusting, spraying, dipping, or brushing a thin mixture of glaze and water onto the unfired pottery. The color of the glaze can change a lot after it's fired. To stop glazed pottery from sticking to the kiln during firing, a small part (like the bottom) is left unglazed, or special supports are used.

Some special glazing techniques include:

- Salt-glazing: Here, common salt is put into the kiln during firing. The high heat turns the salt into a gas, which then sticks to the pottery surface and forms a glaze. This was used a lot in the 17th and 18th centuries for household pottery, but it's rarely used now because of environmental rules.

- Ash glazing: Ash from burning plants has been used as part of glazes. This ash usually came from the kilns themselves. Ash glazes are historically important in the Far East. Today, only a few studio potters use them because the results can be unpredictable, which they enjoy.

Firing

Firing causes permanent changes in the clay. Only after firing does the material become true pottery. In lower-fired pottery, small particles in the clay fuse together where they touch. In porcelain, which uses different materials and higher temperatures, the clay's properties change a lot. The goal of firing is always to make the pottery hard and strong, and the firing process must match the materials used.

The air inside the kiln during firing can also change how the finished pottery looks. Kilns can be heated by burning wood, coal, gas, or by electricity.

Images for kids

-

Forming a vessel using a potter's wheel

-

Earthenware pottery from the Neolithic Longshan culture, China, 3rd millennium BC

-

An electric potter's wheel, with bat (green disk) and throwing bucket. Not shown is a foot pedal used to control the speed of the wheel, similar to a sewing machine

-

Pottery firing mound in Kalabougou, Mali. All the earliest pottery was made in firing pits of this sort

-

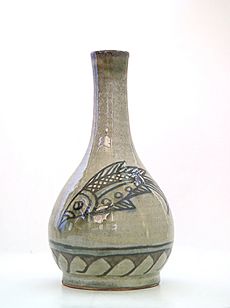

Contemporary pottery from the State of Hidalgo, Mexico

-

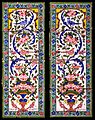

Two panels of earthenware tiles painted with polychrome glazes over a white glaze, Iran, first half of the 19th century.

-

An Incipient Jōmon pottery vessel reconstructed from fragments (10,000–8,000 BC), Tokyo National Museum, Japan

-

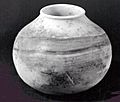

Pottery bowl from Jarmo, Mesopotamia, 7100–5800 BC.

-

Late Neolithic Manunggul Jar from Palawan used for burial, topped with two figures representing the journey of the soul into the afterlife.

-

Before the invention of pottery in Western Asia, during the Pre-Pottery Neolithic: jar in calcite alabaster, Syria, late 8th millennium BC.

-

A potter with his pottery wheel, British Raj (1910)

-

Bowl painted on slip under transparent glaze (polychrome), 9th or 10th century, Nishapur. National Museum of Iran.

-

Spherical Hanging Ornament, 1575–1585, Ottoman Period. Brooklyn Museum.

-

Chess set (Shatrang); Gaming pieces. 12th century, Nishapur glazed fritware. Metropolitan Museum of Art

See also

In Spanish: Alfarería para niños

In Spanish: Alfarería para niños

| Laphonza Butler |

| Daisy Bates |

| Elizabeth Piper Ensley |