Mainspring facts for kids

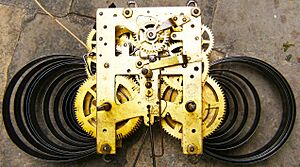

A mainspring is a special spiral spring made of metal ribbon, usually spring steel. It acts like a battery for mechanical watches, some clocks, and other clockwork devices. When you wind a timepiece by turning a knob or key, you twist the mainspring tighter. This stores energy inside it. As the mainspring slowly unwinds, its force turns the gears of the clock or watch. This continues until it needs to be wound again. Things powered by mainsprings are often called wind-up or spring-powered. Besides watches and clocks, this includes kitchen timers, metronomes, music boxes, wind-up toys, and clockwork radios.

Contents

Modern Mainsprings

Today's watch mainsprings are long, thin strips of special steel. They are usually about 20 to 30 centimeters long and very thin (0.05 to 0.2 millimeters thick). A common mainspring for a watch that runs for one day is designed to keep it going for 36 to 40 hours. This gives you about 24 hours of use, plus an extra 12 to 16 hours of "power reserve." This reserve is helpful if you forget to wind your watch on time. Watches that run for 8 days, like some clocks, use longer mainsprings and larger barrels. Clock mainsprings are similar to watch springs, but they are bigger.

Since the 1940s, mainsprings are no longer made just from carbon steel. Newer, special metal alloys are used. These alloys contain metals like iron, nickel, chromium, cobalt, molybdenum, or beryllium. These new "white metal" springs are stainless and much stronger. They are less likely to get permanently bent (become "tired") or break. Some of them are also almost non-magnetic. Popular brands for these alloys include SPRON by Seiko and Nivarox by Swatch Group.

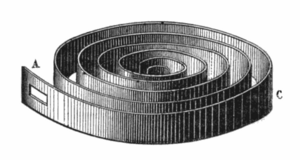

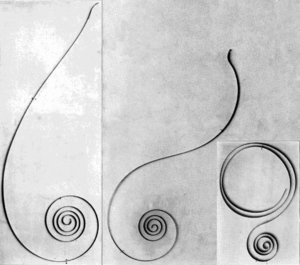

Mainsprings come in three main shapes when they are relaxed:

- Spiral coiled: These are simply coiled in one direction, like a normal spiral.

- Semi-reverse: The very end of the spring coils in the opposite direction for less than one full turn.

- Reverse: The end of the spring coils in the opposite direction for one or more full turns.

The semi-reverse and reverse types help the timepiece run at a more steady speed. They provide extra force when the spring is almost unwound.

How Mainsprings Work

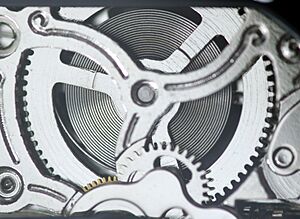

The mainspring wraps around a central rod called the arbor. Its inner end is hooked to this arbor. In many clocks, the outer end of the spring is attached to a fixed post. When you wind the clock, you turn the arbor, which tightens the spring. After winding, the spring unwinds and turns the arbor the other way to power the clock. One problem with this "open spring" design is that the clock might stop while you are winding it. This type is often found in alarm clocks, music boxes, and kitchen timers, where it's okay if they stop briefly during winding. The winding system always has a ratchet and a small lever called a "click." These stop the spring from unwinding on its own.

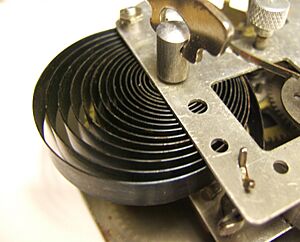

In modern watches, a design called the "going barrel" is used. Here, the mainspring is inside a round metal box called the barrel, which can turn freely. The spring's inner end is attached to the arbor, and its outer end is attached to the inside of the barrel. Small hooks or tabs hold the spring in place, making it easy to replace.

You wind the mainspring by turning the arbor. But the watch is powered by the barrel itself. This clever design allows the watch to keep running even while you are winding it. When you wind the watch, the arbor turns, tightening the mainspring around it. The arbor has a ratchet and click to prevent it from unwinding backward. After winding, the arbor stays still, and the mainspring's pull makes the barrel turn. The barrel has gear teeth around its edge. These teeth connect with other gears in the watch, usually the "center wheel" pinion, driving the entire gear system. The barrel typically turns once every 8 hours. So, a common 40-hour spring needs about 5 turns to fully unwind.

Mainspring Safety

Mainsprings store a lot of energy. If you're not careful when taking a watch or clock apart, the spring can suddenly release. This can cause harm. Before working on a mainspring, experts "let it down" gently. They do this by holding the winding key and carefully releasing the click, allowing the spring to unwind slowly. Even when "let down," mainsprings still have some tension. Watchmakers and clockmakers use special tools called "mainspring winders" to safely put them in or take them out. For large clock mainsprings, "mainspring clamps" are used to hold them still before removal.

Mainspring History

Mainsprings first appeared in clocks in Europe during the 1400s. Before this, clocks were powered by heavy weights hanging from cords. Mainsprings allowed clocks to become much smaller and easier to move around. This led to the first pocketwatches by the 1600s. Many people mistakenly think the German clockmaker Peter Henlein invented the mainspring around 1511. However, records from the 1400s mention portable clocks "without weights," and some old spring-driven clocks still exist from that time. The oldest surviving clock with a mainspring is the Burgundy Clock, made around 1430.

The first mainsprings were made of steel that wasn't specially treated for strength. They didn't run for very long and often needed to be wound twice a day. Peter Henlein was known for making watches that could run for 40 hours between windings.

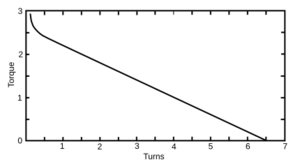

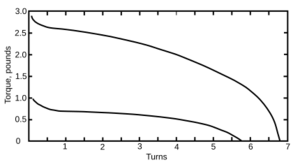

Keeping Constant Power

One big challenge with spring-powered clocks and watches has always been that the force (or "torque") from a spring isn't constant. It gets weaker as the spring unwinds. But timepieces need a steady force to keep accurate time. Early clocks, especially, would slow down as the mainspring ran down, making them less accurate.

Two solutions to this problem appeared in the 1400s: the stackfreed and the fusee.

Stackfreed

The stackfreed was a special cam (a rotating part that changes motion) attached to the mainspring arbor. A spring-loaded roller pressed against it. The cam was shaped like a snail. When the mainspring was strong, the roller pressed against the wide part of the cam, creating a strong opposing force. As the mainspring got weaker, the roller moved to the narrower part of the cam, and the opposing force also decreased. The stackfreed created a lot of friction, which made clocks run for shorter times. It was only used in some German timepieces and disappeared after about 100 years.

Fusee

The fusee was a much more successful invention. It was a cone-shaped pulley that was turned by a chain wrapped around the mainspring barrel. Its curved shape constantly changed how much power was transferred. This helped to even out the mainspring's force as it unwound. Fusees became the standard way to get constant power from a mainspring. They were used in most spring-driven clocks and watches until the 1800s, when the going barrel became more common. They were even used in marine chronometers (very accurate ship clocks) until the 1970s.

Stopwork

Another early device that helped keep the spring's force even was called stopwork or winding stops. These devices stopped the mainspring from being wound too tightly and from unwinding completely. The idea was to use only the middle part of the spring's power, where its force was more constant. The most common type was the Geneva stop or 'Maltese cross'. Modern watches don't usually need stopwork.

Remontoire

A fourth device, used in a few very precise timepieces, was the remontoire. This was a small, secondary spring or weight that powered the clock's escapement (the part that ticks). The mainspring would then rewind this small secondary spring regularly. This separated the timekeeping part from the mainspring's changing force.

Going Barrel

The modern going barrel, invented in 1760 by Jean-Antoine Lépine, creates a constant force in a simpler way. It uses a mainspring that is longer than needed and is coiled tightly inside the barrel. When the watch is running, only a few turns of the spring are actively unwinding. The rest of the spring stays pressed against the outer wall of the barrel. This design creates a "flat" section in the spring's power curve, meaning it provides a steady force. Also, the outer end of the spring is often shaped like an "S." This stores more tension in the outer turns, which helps provide power towards the end of the running time. As a result, the barrel provides almost constant power throughout the watch's designed running period. The power only drops when the mainspring is almost completely unwound.

Because of the tension inside, a mainspring in a going barrel can be dangerous to take apart, even when it's not wound up.

Broken Mainsprings

Mainsprings are constantly stressed by winding and unwinding. Until the 1960s, they often broke due to metal fatigue (weakening from repeated stress) before other parts of the timepiece wore out. They were expected to be replaced. This often happened when the spring was wound too tightly, with no space left between its coils. If you wound a watch manually, it was easy to wind it too much and put too much pressure on the spring. Temperature changes could also cause breaks. If a watch was fully wound at night and the temperature dropped, the long spring would shrink. If there was no slack, this could break it from its attachments. In the past, watch repairers noticed more broken mainsprings when the weather changed. Broken mainsprings were the most common watch repair until the 1960s. Since then, better spring metallurgy (metal science) has made broken mainsprings rare.

'Knocking' or 'Banking'

Even if mainsprings didn't break, too much force during winding caused another problem in older watches, called 'knocking' or 'banking'. If the spring was wound too tightly, the last turn of the winding knob put too much tension on the end of the spring. This extra tension would make the watch run too fast for several hours. It caused the balance wheel (the part that swings back and forth) to rotate too far. This could make a small pin on the wheel hit the wrong part of the escapement, making the watch gain time and possibly breaking the pin. In older watches, 'stopwork' prevented this. In modern watches, the 'click' (the small lever that stops the spring from unwinding) is designed to allow the arbor to turn back slightly after winding. This releases any extra tension.

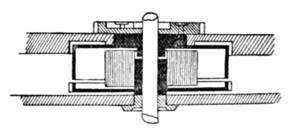

Motor or Safety Barrel

Around 1900, when broken watchsprings were a bigger problem, some pocketwatches used a different type of going barrel called the motor barrel or safety barrel. Mainsprings usually broke where they attached to the arbor, as this is where the most bending stress occurs. When a mainspring broke, the outer part would snap back, and the barrel would spin backward very fast. This could damage the delicate gear system and escapement, often breaking small pivots and jewels.

In the motor barrel, the roles of the arbor and barrel were swapped. The mainspring was wound by the barrel, but it turned the arbor to power the gears. So, if the mainspring broke, the damaging recoil of the barrel would affect the winding mechanism, which was strong enough to handle it, instead of the delicate gears.

Safety Pinion

A safety pinion was another way to protect the watch, used with the going barrel. In this design, the center wheel pinion (a small gear that the barrel gear connects to) was attached to its shaft with a reverse screw thread. If the spring broke, the backward recoil of the barrel would simply unscrew the pinion instead of damaging the gear train.

The Myth of 'Overwinding'

Watches and clocks are often found stopped with their mainsprings fully wound. This led to a common belief that winding a spring-powered timepiece too much can damage it. However, timepieces are designed to be wound all the way up. The problem is never truly "overwinding."

One reason a watch might stop when fully wound is dirt. Watch movements need to be cleaned and oiled regularly. If this isn't done, dirt builds up and the oil dries, increasing friction. The mainspring then doesn't have enough force to run the watch for its full time, and it stops early. If the owner keeps winding and using the watch without servicing, the friction eventually becomes so high that the mainspring can't power the watch even when fully wound. The watch needs service, but the problem is caused by a dirty movement or another issue, not "overwinding."

Another common reason a watch stops when fully wound is if it's dropped. The balance staff (a tiny rod in the balance wheel) can break, and then the watch can't run even with a fully wound mainspring.

Self-Winding Watches and 'Unbreakable' Mainsprings

Self-winding or automatic watches, which became popular in the 1950s, use the natural movements of your wrist to keep the mainspring wound. A half-circle weight inside the watch swings with each wrist motion. A special winding system uses these movements to wind the mainspring.

In automatic watches, your wrist motion could keep winding the mainspring until it broke. To prevent this, a slipping clutch device is used. The outer end of the mainspring isn't firmly attached to the barrel. Instead, it's connected to a circular spring called a bridle. This bridle presses against the inside wall of the barrel, which has small grooves to hold it. During normal winding, the bridle holds onto the barrel by friction, allowing the mainspring to wind. But when the mainspring is fully wound and reaches its maximum tension, its pull becomes stronger than the bridle's grip. Any further winding causes the bridle to slip along the barrel, stopping more winding. Watch companies sometimes call this an 'unbreakable mainspring', but it just means it won't break from being overwound.

'Tired' or 'Set' Mainsprings

After many years of use, mainsprings in older timepieces can slightly change shape and lose some of their power. This is called becoming 'tired' or 'set'. It mostly happens to springs inside barrels. When a spring is tired, the watch or clock will run for a shorter time between windings. During maintenance, a mainspring should be checked for tiredness and replaced if needed. The British Horological Institute suggests these tests:

- In a mainspring barrel, when the spring is unwound and relaxed, most of a healthy spring's coils should be pressed flat against the barrel wall. Only 1 or 2 coils should spiral across the center to connect to the arbor. If more than 2 coils are loose in the center, the spring might be 'tired'. If there are 4 or 5 loose coils, it is definitely 'tired'.

- If you take the spring out of the barrel and lay it flat, a healthy spring's relaxed diameter should be at least 2½ times the barrel's diameter. If it's smaller, it's 'tired'.

Power Reserve Indicator

Some high-quality watches have an extra dial on their face that shows how much power is left in the mainspring. This is often marked in hours, telling you how much longer the watch will run. Since both the arbor and the barrel turn, this feature uses a differential gear to measure how much the arbor has turned compared to the barrel.

Unusual Mainsprings

A mainspring is usually a coiled metal spring, but there are some rare exceptions:

- Wagon spring clocks: For a short time in American clockmaking, it was hard to get coilable spring steel. So, some clever clockmakers built clocks powered by a stack of leaf springs. These were similar to the springs used in old wagons for suspension.

- Other types of springs have been tried in experimental timepieces.

- Occasionally, you might find an unusual clock with a spring made of something other than metal, like synthetic elastic materials.

| Bayard Rustin |

| Jeannette Carter |

| Jeremiah A. Brown |