Marine chronometer facts for kids

Quick facts for kids Marine chronometer |

|

|---|---|

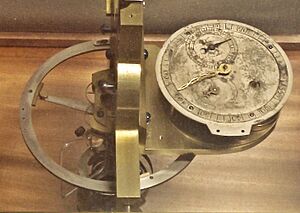

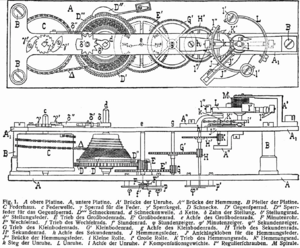

A marine chronometer by Charles Frodsham of London, shown turned upside down to reveal the movement. Chronometer circa 1844-1860.

|

|

| Classification | Clock |

| Industry | Transportation |

| Application | Timekeeping |

| Powered | No |

| Inventor | John Harrison |

| Invented | 1761 |

A marine chronometer is a super accurate clock used on ships. It helps sailors figure out where they are on the ocean. It does this by comparing the time on the ship to a special time called Greenwich Mean Time (GMT). Knowing both times helps them find their longitude (their east-west position).

Back in the 1700s, when there was no GPS or radio, this clock was a huge invention! Knowing the exact time during long sea trips was super important for finding your way. The first real chronometer was the life's work of one man, John Harrison. He spent 31 years experimenting and testing, which completely changed how ships (and later planes) navigated.

The word chronometer comes from two Greek words. Chronos means time, and meter means measure. So, it means "time measure." Today, the word "chronometer" is also used for watches that have been tested and certified to be very precise.

Contents

How did sailors find their way?

To know exactly where you are on Earth, you need to know your latitude (how far north or south you are) and your longitude (how far east or west you are). For ships at sea, altitude (how high up you are) doesn't really matter.

Before the mid-1700s, it was really hard to navigate at sea when you couldn't see land. Sailors could find their latitude by looking at the sun at noon. In the Northern Hemisphere, they could also use the North Star. But finding their longitude was a big problem. They needed a clock that would work perfectly on a moving ship.

Watching things like Jupiter's natural satellites to tell time didn't work well on a rocking ship. Another method, called the lunar distances method, was also being developed. But the idea of using a super accurate clock to find longitude was first suggested in 1530 by a Dutch scientist named Gemma Frisius.

Why was a precise clock so important?

The Earth spins at a steady speed. If you know the exact time at a fixed place (like Greenwich, England) and the exact time where your ship is, you can figure out your longitude. Every four seconds your clock is off, your east-west position could be wrong by more than one nautical mile!

To navigate using the stars, sailors needed a marine chronometer for time. They also used a sextant to measure angles of stars or the sun. A special book called an almanac told them where celestial objects would be. They also used tables to help with calculations. With these tools, finding your position became much easier.

Making a clock that worked well at sea was very difficult. Regular pendulum clocks were the best clocks on land. But the rocking of a ship and small changes in gravity of Earth made pendulums useless at sea.

Who invented the marine chronometer?

Early attempts

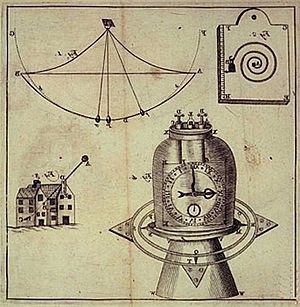

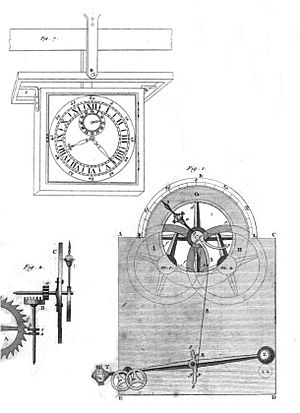

After inventing the pendulum clock in 1656, Christiaan Huygens tried to make a marine chronometer in France in 1673. In 1675, Huygens invented a clock that used a balance wheel and a spiral spring instead of a pendulum. This was a big step towards modern watches and marine chronometers. However, his clock wasn't accurate enough at sea.

The first time the word chronometer appeared in print was in 1684. In 1713, English scientist William Derham also described a chronometer. He even suggested sealing clocks in a vacuum to make them more accurate.

Jeremy Thacker in England (1714) and Henry Sully in France (1716) also tried to build working marine chronometers. But their clocks couldn't handle the ship's movements and keep accurate time.

John Harrison's amazing journey

In 1714, the British government offered a huge longitude prize for a way to find longitude at sea. The prize was between £10,000 and £20,000. That's like £2 million to £4 million today!

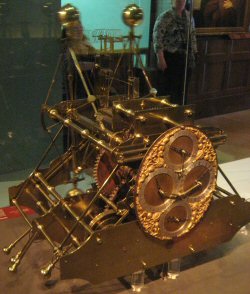

John Harrison, a carpenter from Yorkshire, England, started working on a solution in 1730. In 1735, he finished his first clock, called H1. It used special swinging beams that weren't affected by gravity or the ship's motion. His first two clocks, H1 and H2 (finished in 1741), used this system. But he realized they were still sensitive to centrifugal force, meaning they couldn't be precise enough.

His third machine, H3, built in 1759, had new circular balances. He also invented the bi-metallic strip (used in thermostats today) and caged roller bearings. Even with these inventions, H3 wasn't accurate enough, so he stopped working on the large machines.

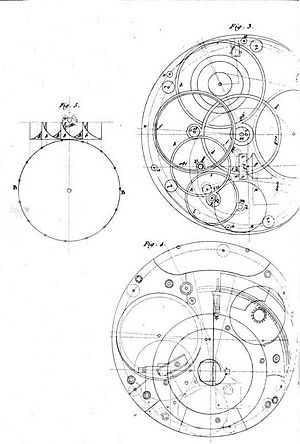

Harrison finally solved the problem with his much smaller H4 chronometer in 1761. H4 looked a lot like a large pocket watch, about five inches across. In 1761, Harrison submitted H4 for the £20,000 prize. His design used a fast-moving balance wheel with a spring that was designed to work well even when the temperature changed. These ideas were used in clocks for a very long time.

In 1767, the Board of Longitude published a book describing Harrison's work. The first time chronometers were used by a French expedition to measure longitude was in 1767.

Further improvements

In France, in 1748, Pierre Le Roy invented a key part of modern chronometers called the detent escapement. In 1766, he made a revolutionary chronometer. It had the detent escapement, a temperature-compensated balance, and an isochronous balance spring. Harrison showed that a reliable chronometer was possible, but Le Roy's improvements made them much more accurate.

Other clockmakers like Ferdinand Berthoud in France and Thomas Mudge in Britain also made successful marine clocks. This showed that Harrison's design wasn't the only way to solve the problem.

The biggest steps towards making chronometers practical came from Thomas Earnshaw and John Arnold. In 1780, they developed simpler escapements and improved the design of balance springs. Their ideas became the basis for marine chronometers until the age of electronics.

At first, these new clocks were very expensive. Not all ships had them. For example, the ship Arniston was shipwrecked in 1815, and 372 lives were lost, partly because it didn't have a chronometer. However, by 1825, the Royal Navy started giving chronometers to all its ships.

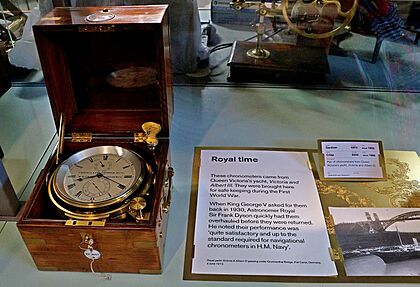

From 1820, the British Royal Observatory in Greenwich tested marine chronometers. This was to encourage makers to improve them. These tests continued until World War I.

Observatories in Europe also tested chronometers. If a clock passed these tough tests, it was certified as an observatory chronometer. It received a special certificate showing how well it performed.

It was common for ships to check their chronometers before a long trip. They would watch a time ball (like the one at the Royal Observatory, Greenwich) drop at exactly 1 pm. This helped make Greenwich Mean Time an international standard. Time balls became less important around 1920 when radio time signals started. Today, GPS time is used.

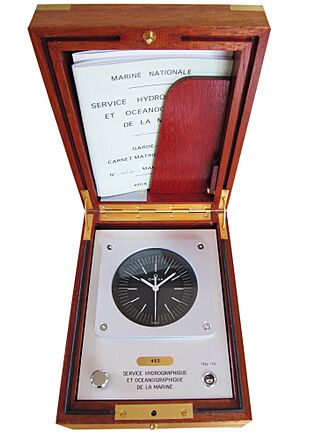

Sailors usually kept the chronometer safely below deck in a special box. This box was suspended in gimbals (a set of rings). This kept the chronometer flat and steady, even when the ship rocked. Sailors would use the chronometer to set a less accurate "hack watch," which they took on deck for observations.

Making chronometers faster

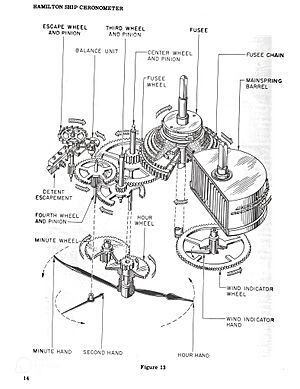

Even as factories started making watches in the mid-1800s, chronometers were still mostly made by hand. Around 1900, Swiss makers like Ulysse Nardin started using modern production methods. But it was during World War II that the Hamilton Watch Company in the United States perfected mass production. They made thousands of their Model 21 and Model 22 chronometers for the US military and its Allied forces.

Germany also developed a "unified chronometer" design during World War II. This allowed different companies to make parts that could be swapped. Production of these German chronometers continued after the war in Germany and the Soviet Union. The German unified design became the most produced mechanical marine chronometer ever, with about 58,000 units made.

Despite this mass production, some companies like Thomas Mercer Chronometers still made chronometers the old way.

Why were they so important?

Marine chronometers are the most precise portable mechanical clocks ever made. Only very large, non-portable pendulum clocks in observatories were more accurate. These clocks, along with the sextant, helped ships find their location at sea. Countries invested a lot in them because knowing your exact position gave a big advantage in naval power.

Some historians argue that the rise of the Royal Navy and the British Empire might not have happened without the chronometer. British ships had reliable navigation, while their rivals like Portugal, the Netherlands, and France did not. For example, Britain defeated France in the Seven Years' War partly because of its naval strength.

Keeping chronometers accurate was important well into the 20th century. After World War I, the British Royal Observatory continued to test and repair them for the navy.

From the 1960s, mechanical chronometers were slowly replaced by electric ones. By the end of the 20th century, only a few companies still made mechanical marine chronometers.

The best collection of marine chronometers, including Harrison's H1 to H4, is at the Royal Observatory, Greenwich, in London, UK.

How do they work?

The biggest challenge was finding a part that wouldn't be affected by the ship's movement or temperature changes. The balance wheel, connected to a spring, solved most of the problems with ship motion.

However, the strength of most balance springs changes with temperature. To fix this, many chronometers used bi-metallic strips. These strips would move tiny weights on the balance, changing how fast it swung to match the spring's changing strength. The problem of the balance spring was finally solved with a special metal alloy called Elinvar. It has unchanging elasticity at normal temperatures. Charles Édouard Guillaume won the 1920 Nobel Prize for physics for inventing it.

The escapement is the part that makes the clock "tick." It lets the clock's gears move forward a tiny bit and keeps the balance wheel swinging. Chronometer escapements are designed to interfere with the balance as little as possible. The most common types are the spring detent and pivoted detent.

In these escapements, a small part called a detent locks the escape wheel. This lets the balance swing freely for most of its movement. Only for a brief moment, when the balance is at its fastest point, does it unlock the detent. This allows one tooth of the escape wheel to pass, giving a tiny push to the balance. This push keeps the balance swinging.

A weak point in any mechanical clock is the lubrication. If the oil gets thick or dries out, the clock's accuracy can change a lot. A detent escapement has a big advantage because it needs almost no lubrication.

Chronometers often had other cool features to make them better. Hard stones like ruby and sapphire were used as jewel bearings to reduce friction and wear. Diamonds were sometimes used for the main pivot of the balance wheel. Makers kept trying new things like ball bearings and chrome-plated parts until mechanical chronometers stopped being made.

These clocks were usually kept safe below deck in a special box. The box was suspended in gimbals. This kept the chronometer level and steady, even when the ship was rocking.

Marine chronometers also had a maintaining power feature. This kept the clock running while it was being wound. They also had a power reserve indicator to show how long they would run before needing to be wound again.

All these clever designs usually made mechanical marine chronometers accurate to within half a second per day!

How chronometers were rated

Before a chronometer was used, it was "rated." This meant its average daily gain or loss was carefully measured and recorded on a certificate. Sailors would use this daily rate to correct the time shown on the chronometer. Even the best chronometers had tiny errors. Rating helped to account for these small, consistent errors. On long trips, sailors would check the chronometer's rate again using observations of the stars.

Marine chronometers today

Since the 1990s, ships use satellite navigation systems like GPS to find their way. These systems have many features useful for sailors, like "man overboard" functions. GPS can also connect to a ship's steering and map systems.

Even with all this modern technology, many professional sailors still learn and use celestial navigation. This means they use electric-powered time sources (like modern chronometers) along with satellite navigation. Using different ways to find your position helps you spot errors and is a good backup if electronic systems fail.

Modern marine chronometers are often quartz clocks. They can be corrected by satellite time signals or radio time signals. Some very accurate quartz clocks can be accurate to within 5 or 20 seconds per year, even without a signal. Some advanced quartz chronometers even use multiple quartz crystals and computers to be super precise.

See also

- Celestial navigation

- Sextant

- Clockmaker

- Thomas Earnshaw, inventor of the standard chronometer escapement

- Larcum Kendall

- Noon Gun

- Time ball

- Time signal

- Railroad chronometer

- Rupert Gould, author of an important history of the marine chronometer

- Radio-controlled watch

- Watchmaker

- Timeline of invention

- Longitude (book)

| Laphonza Butler |

| Daisy Bates |

| Elizabeth Piper Ensley |