Manufacturing engineering facts for kids

Manufacturing engineering is a cool part of engineering that helps make things. It's like a mix of mechanical, chemical, electrical, and industrial engineering.

Manufacturing engineers figure out how to make products. They invent tools, machines, and ways to produce things. Their goal is to make high-quality products using the best methods and spending money wisely.

A manufacturing engineer's main job is to change raw materials into new products. They want to do this in the smartest, fastest, and cheapest way. For example, they might use computers to make products quicker with less human effort.

Contents

What is Manufacturing Engineering?

Manufacturing engineering uses ideas from industrial engineering and mechanical engineering. It also includes parts of robotics, business, and money management.

This field helps put together different systems to make good products. They use science and studies of how factories work. Here are some ways things have been made throughout history:

- Craft (making things by hand)

- Putting-out system (work done at home)

- British factory system (early factories)

- American system of manufacturing (making parts that fit everywhere)

- Mass production (making many of the same thing)

- Computer integrated manufacturing (computers control everything)

- Computer-aided technologies (using computers to help)

- Just in time (making things only when needed)

- Lean manufacturing (reducing waste)

- Flexible manufacturing (easy to change what's made)

- Mass customization (making things unique for each person)

- Agile manufacturing (quick to adapt)

- Rapid manufacturing (making things fast with 3D printers)

- Prefabrication (making parts somewhere else)

- Fabrication (building metal structures)

- Publication (making books or magazines)

Manufacturing engineers design and create physical products. They also make the processes and technology to build them. This area is very wide, including how products are designed and developed. It's a big part of industrial engineering and mechanical engineering. What these engineers do directly affects how technology grows and new ideas spread. This field started in the early 1900s. It grew a lot from the 1960s when factories started using:

- Computer-controlled machines: These machines could do tasks automatically.

- Better quality control: An American engineer named William Edwards Deming helped create ways to check product quality. These methods later made Japanese factories world leaders.

- Factory robots: Robots came into factories in the late 1970s. These computer-controlled arms could do simple jobs like attaching a car door. They worked quickly and perfectly, 24 hours a day. This helped factories save money and make things faster.

History of Making Things

The story of manufacturing engineering goes back to factories in the 1800s in the USA and the 1700s in the UK. But even before that, the Venetian Arsenal in Italy was like an early factory. Started in 1104, it built ships on assembly lines using ready-made parts. It could make almost one ship every day and had 16,000 workers!

Many people think Matthew Boulton's Soho Manufactory (1761 in England) was the first modern factory. Other early factories include John Lombe's silk mill (1721) and Richard Arkwright's Cromford Mill (1771). The Cromford Mill was built just for the machines it held.

In the 1800s, British colonies built factories where many workers did hand labor, often making textiles. This was better than making things at home.

Cotton mills used new inventions like the steam engine and the power loom. These helped create the industrial factories of the 1800s. Here, precise machines and parts that could be swapped out made things more efficient. This led to the study of manufacturing engineering.

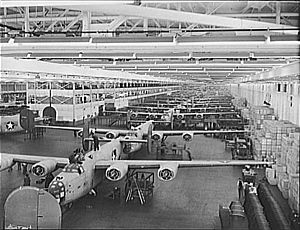

Henry Ford changed factories even more in the early 1900s with mass production. Workers specialized in one task along a moving assembly line. This greatly lowered the cost of almost everything made. It helped start the age of buying many consumer goods.

Newer Ways of Making Things

Today, manufacturing engineering looks at all the steps needed to make and put together a product.

Some industries, like those making computer chips or steel, call these processes "fabrication."

Automation means using machines to do tasks automatically. In factories, automation helps make goods. The main benefits are:

- More consistent quality.

- Faster production times.

- Simpler production.

- Less handling of products.

- Better work flow.

- Happier workers.

Robotics is about creating robots, often used in factories. Robots do jobs that are dangerous, boring, or repeated many times. They can be any shape or size, but they are programmed and interact with the world. Engineers use math to figure out how robots move and how strong they need to be. Robots are used a lot in manufacturing.

Robots help businesses save money on labor. They can do tasks too dangerous or too precise for humans. They also help ensure better quality. Many companies use assembly lines of robots. Some factories are so full of robots that they can run by themselves!

Becoming a Manufacturing Engineer

Manufacturing engineers focus on designing and running systems that make products. These systems can include machines that move materials, tools, robots, or even computers. Their goal is to make high-quality products that are also affordable.

How to Study Manufacturing Engineering

To become a manufacturing engineer, you usually need a college degree. This can be an Associate's or Bachelor's degree in engineering, often taking two to five years. After that, you might need more years of work experience to become a professional engineer.

College courses for manufacturing engineers often include:

- Math (like calculus and statistics)

- Science (like physics and materials science)

- Computer science

- Project management

- Specific topics in mechanical and manufacturing engineering.

Students usually learn about many areas of manufacturing engineering first. Then, they choose to focus on one or more specific areas later in their studies.

Some common topics in manufacturing engineering studies are:

- How things move and balance (Mechanics)

- How strong materials are

- How liquids and gases behave (Fluid Dynamics)

- Heating and cooling systems

- How heat moves

- Energy and power

- Measuring things

- Drawing and designing parts (Engineering Drawing)

- How machines work

- Different ways to make things (Manufacturing Processes)

- Combining electronics and mechanics (Mechatronics)

- Computer-aided design (CAD) and manufacturing (CAM)

- Making things with less waste (Lean Manufacturing)

- Making things automatically (Automation)

- Taking things apart to see how they work (Reverse Engineering)

- Checking product quality

Manufacturing engineering degrees are very similar to mechanical engineering degrees. However, manufacturing engineering focuses more on the science of making things. Mechanical engineering often focuses more on designing complex products.

Modern Tools for Engineers

Many manufacturing companies use computer programs to help design and analyze products. These are called computer-aided engineering (CAE) programs. They include 2D and 3D computer-aided design (CAD) tools. These tools have many benefits:

- It's easier to see what products will look like.

- You can create virtual models of parts put together.

- It's simple to design how parts fit.

Other CAE programs help manage the product's entire life cycle. They also run complex tests. These tests can predict how a product will react to forces, how long it will last, and how easy it will be to make. Examples include finite element analysis (FEA) and computational fluid dynamics (CFD).

Using CAE programs, engineers can quickly try out many designs. This helps them create products that meet cost and performance goals. They don't need to build a real model until the design is almost finished. This means they can test hundreds of designs instead of just a few.

Manufacturing Engineering Around the World

Manufacturing engineering is very important everywhere. It has different names in different countries. In the United States and Europe, it's often called Industrial Engineering. In the United Kingdom and Australia, it's usually called Manufacturing Engineering.

What Manufacturing Engineers Study

Mechanics

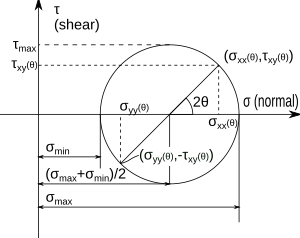

Mechanics is the study of forces and what they do to objects. Engineers use mechanics to figure out how objects will move or change shape when forces are applied. Some parts of mechanics include:

- Statics: Studying objects that are not moving.

- Dynamics: Studying how forces affect moving objects.

- Mechanics of materials: Studying how different materials change shape under stress.

- Fluid mechanics: Studying how liquids and gases react to forces.

For example, if an engineer is designing a car, they might use statics to design the car's frame. This helps them see where the forces will be strongest. They might use dynamics to design the engine. Mechanics of materials helps them choose the right materials for the car. Fluid mechanics can help design the car's ventilation system.

Kinematics

Kinematics is the study of how things move, without worrying about the forces that cause the movement. Think about how a crane moves or how a piston goes up and down in an engine. Engineers use kinematics to design and analyze machines. They can figure out how much a machine can move. Or, they can design a machine to move in a specific way.

Drafting (Technical Drawing)

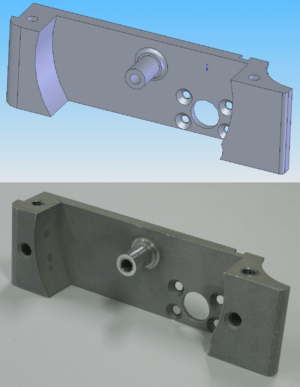

Drafting, or technical drawing, is how engineers create instructions for making parts. A technical drawing can be a computer model or a hand-drawn picture. It shows all the sizes needed to make a part. It also includes notes on how to put parts together, a list of materials, and other important details.

Today, engineers often use computer-aided design (CAD) programs. These programs let them design in 3D. The instructions from these drawings are then sent to machines, often through computer-aided manufacturing (CAM) programs. This is called computer numerically controlled (CNC) manufacturing.

Drafting is used in almost every type of engineering. 3D models from CAD software are also used for testing, like finite element analysis (FEA).

Machine Tools and Metal Work

Machine tools use a special tool to cut or shape materials. All machine tools hold the material firmly and guide the cutting tool. Metal fabrication is about building metal structures. This involves cutting, bending, and putting metal pieces together.

Computer Integrated Manufacturing (CIM)

Computer-integrated manufacturing (CIM) is a way of making things where computers control the whole production process. It connects different parts of the factory through computers. This helps processes share information and start actions. CIM makes manufacturing faster and reduces mistakes. Its main benefit is creating automated factories.

Mechatronics

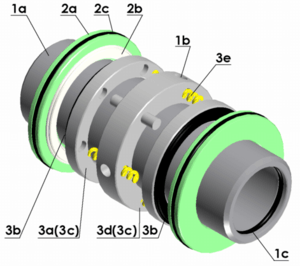

Mechatronics is an engineering field that combines electrical, mechanical, and manufacturing systems. These combined systems are called electromechanical systems. You can find them everywhere! Examples include automated factories, heating and cooling systems, and parts of airplanes and cars.

The term mechatronics usually refers to larger systems. But tiny electromechanical devices, called Microelectromechanical systems (MEMS), are also being developed. MEMS are already used in cars to deploy airbags and in printers for high-quality printing. In the future, they might be used in tiny medical devices or to improve communication.

Textile Engineering

Textile engineering is about using science and engineering to design and control everything related to fibers, fabrics, and clothing. This includes natural and man-made materials, how materials work with machines, safety, saving energy, and reducing waste. Students also learn how to design factories and improve machines.

Advanced Composite Materials

Advanced composite materials (engineering) (ACMs) are also known as advanced polymer matrix composites. These materials are super strong and stiff, much more than other materials. They are made of strong fibers held together by weaker glues. ACMs are used a lot in aircraft, spacecraft, and sports equipment. Making ACMs is a huge industry worldwide. These materials are used in everything from skateboards to parts of the space shuttle.

Where Manufacturing Engineers Work

Manufacturing engineering is a big part of the engineering industry. Manufacturing engineers love making production processes better, from start to finish. They think about the whole process while focusing on one part of it. Students who enjoy manufacturing engineering are excited about taking something natural, like a block of wood, and turning it into a useful product, like a desk, in a smart and cheap way.

Manufacturing engineers work closely with design teams. Big companies that hire manufacturing engineers include General Motors, Ford Motor, Chrysler, Boeing, and Airbus.

Manufacturing engineers work in many industries, such as:

- Aerospace industry (planes and spacecraft)

- Automotive industry (cars)

- Chemical industry

- Computer industry

- Food processing industry

- Garment industry (clothing)

- Pharmaceutical industry (medicines)

- Pulp and paper industry

- Toy industry

New Ideas in Manufacturing Engineering

Flexible Manufacturing Systems (FMS)

A flexible manufacturing system (FMS) is a factory system that can easily change. It can adapt to planned or unplanned changes. This flexibility comes in two main types:

- Machine flexibility: The system can change to make new products or change the order of steps.

- Routing flexibility: It can use different machines for the same job. It can also handle big changes in how much is produced.

Most FMS systems have three main parts: 1. Work machines: Often automated, like CNC machines. 2. Material handling system: Moves parts between machines. 3. Central control computer: Manages all movements and machines.

The main benefit of an FMS is its high flexibility. It can manage resources like time and effort to make new products. FMS works best for making small batches of different products, rather than mass production.

Computer Integrated Manufacturing (CIM)

Computer-integrated manufacturing (CIM) is a way of making things where computers control the entire production process. It connects different parts of the factory through computers. This allows processes to share information and start actions. With CIM, manufacturing can be faster and have fewer errors. The main advantage is creating automated factories. CIM often uses sensors to get real-time information and control processes.

Friction Stir Welding

Friction stir welding was invented in 1991. This new welding method can join materials that were hard to weld before, like some aluminum alloys. It might be very important for building airplanes in the future, possibly replacing rivets.

Today, this technology is used to weld parts of the space shuttle, rockets, armor for ships, and airplane wings.

Other new areas of research include:

- Product Design

- MEMS (Micro-Electro-Mechanical Systems)

- Lean Manufacturing

- Intelligent Manufacturing Systems

- Green Manufacturing (making things in an environmentally friendly way)

- Precision Engineering

- Smart Materials

See also

In Spanish: Ingeniería de manufactura para niños

In Spanish: Ingeniería de manufactura para niños

| Tommie Smith |

| Simone Manuel |

| Shani Davis |

| Simone Biles |

| Alice Coachman |