Steam power during the Industrial Revolution facts for kids

The steam engine was a super important invention during the time known as the Industrial Revolution. Even though water power was still used a lot, steam engines changed how factories and mines worked.

Before steam engines, factories had to be built near rivers for water power. But water levels could change with the seasons. With a steam engine, a factory could be built almost anywhere! This was a huge step forward.

In 1776, James Watt teamed up with Matthew Boulton to build engines. Their company, Boulton & Watt, became a key part of the Industrial Revolution. They solved tough technical problems and shared their solutions with other businesses. This sharing of ideas helped technology grow much faster. It meant companies didn't have to spend as much time and money figuring things out on their own.

Even with the rise of steam, it's good to remember that for most of the Industrial Revolution, many industries still used power from wind, water, horses, and even people for smaller machines.

Contents

Early Steam Engines

The idea of using steam power for industry started with Thomas Savery in 1698. He built and patented the first steam engine in London. He called it the "Miner's Friend" because he wanted it to pump water out of mines.

Savery's early engines had copper boilers that could burst easily. Later versions used iron boilers and could lift water about 46 meters (150 feet). His engine had no moving parts except for valves operated by hand. It worked by creating a vacuum with cold water, which pulled water up. Then, steam pushed the water higher. This engine wasn't very successful because it couldn't pump water very high and its boilers often exploded.

Newcomen's Engine

The first truly useful mechanical steam engine was introduced by Thomas Newcomen in 1712. Newcomen likely came up with his idea on his own. However, because Savery had a broad patent, Newcomen had to work with him. They sold the engine together until 1733.

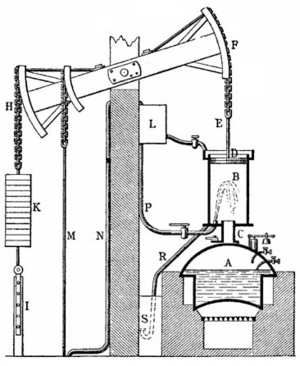

Newcomen's engine used a piston and cylinder. Steam was let into the cylinder, then cold water was sprayed in to cool the steam. This created a vacuum. The air pressure from outside then pushed the piston down. This downward movement powered a rocking beam, which in turn operated pumps in the mineshaft.

At first, people had to control the engine by hand. But within ten years, a clever system was invented that made the engine work by itself.

Many Newcomen engines were successfully used in Britain to drain deep mines that couldn't be worked before. These were big machines, expensive to build, and produced about 5 horsepower. They weren't very efficient, but they were great for coal mines where coal was cheap. They allowed mines to go much deeper, helping the coal mining industry grow a lot.

Newcomen engines were reliable and easy to keep running. They were used in coalfields until the early 1800s. By the time Newcomen died in 1729, his engines had spread to other countries like France and Germany. By 1733, 110 of these engines had been built. Later, by 1800, a total of 1,454 Newcomen engines were built.

Watt's Improved Steam Engines

A big change in how steam engines worked came from James Watt. Working closely with Matthew Boulton, Watt perfected his steam engine by 1778. He made some major improvements. The most important was adding a separate chamber to condense the steam, away from the main piston cylinder.

These improvements made Watt's engine about five times more efficient. This meant it used 75% less coal, saving a lot of money!

Around 1783, Watt fully developed a new type of engine that could create a spinning motion. This engine had a centrifugal governor (to control speed) and a flywheel (to make the motion smooth). This meant it could directly power the spinning machines in a factory or mill. Both of Watt's main engine types were very successful.

By 1800, Boulton & Watt had built 496 engines. Many of these powered factory machines. These engines usually produced 5 to 10 horsepower. While impressive, this was still less than the total power from waterwheels and windmills in Britain at the time. However, water and wind power depended on the weather, while steam engines could run anytime.

Steam Engine Development After Watt

After Watt's patent ran out in 1800, steam engines became much more powerful. This was because engineers started using higher-pressure steam. Watt had avoided this due to the danger of boilers exploding, as they were not very strong back then.

Early steam engines were often built right into stone or brick buildings. But soon, smaller, self-contained engines were developed that could be moved more easily.

Towards the end of the 1700s, engineers like Richard Trevithick in England and Oliver Evans in America started building higher-pressure engines. These engines released their steam into the air. This made it possible to combine the engine and boiler into one unit. This new design was compact and light enough to be used in mobile machines like locomotives for trains and steam boats.

Trevithick also developed a large boiler with an internal flue around 1812. These were used to upgrade some of Watt's older pumping engines.

The Cornish engine was developed in the 1810s for pumping water out of mines in Cornwall. It was known for being quite efficient.

The Corliss Engine

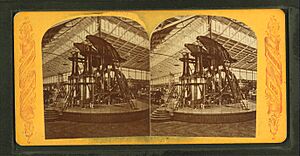

A very important improvement to the steam engine was the Corliss engine, introduced in 1849 by George Henry Corliss. This engine had many great features. It used less fuel, needed less maintenance, and produced 30% more power. It could also keep a steady speed even when the workload changed a lot.

The Corliss engine looked like other steam engines with its piston and flywheel. But its special valves and valve gears made it stand out. Instead of simple slide valves, Corliss created a system with a "wrist plate" that controlled four separate valves for each cylinder. These valves opened and closed precisely, letting steam in and out at just the right time.

This precise control allowed for an "automatic variable cut-off mechanism." This meant the engine could adjust its power to match the load without slowing down, stopping, or getting damaged. This was super useful! For example, in the textile industry, it allowed machines to run much faster without breaking threads. In metallurgy, it helped with the sudden changes in load when working with metal in rolling mills. The Corliss engine helped factories produce much more, while also preventing costly damage. It was called "the most perfect regulation of speed."

Corliss kept detailed records of his engines. By 1869, nearly 1,200 Corliss engines had been sold, producing a total of 118,500 horsepower. Even more horsepower came from engines made by others who copied his design. In 1870, the average Corliss engine produced 100 horsepower, while other steam engines averaged 30 horsepower. Some very large Corliss engines could even reach 1,400 horsepower!

Many people saw the benefits of the Corliss engine, but it was slow to be adopted at first because of Corliss's patent protection. When his patent expired in 1870, it quickly became a popular model for stationary engines in factories. By the end of the 1800s, Corliss engines made up only 10% of factory engines but produced 46% of the total horsepower!

The Corliss engine was also used for pumping water and helped the railroad grow by powering large rolling mills. Even today, some Corliss engines are still used in distilleries as a power source, showing how long-lasting they are.

Major Uses of Steam Power

Powering Blast Furnaces

In the mid-1750s, steam engines started to be used in the iron, copper, and lead industries. They powered the huge bellows that blew air into blast furnaces. These furnaces were often near mines that already used steam engines to pump water.

Steam engines were too powerful for old leather bellows, so new cast iron blowing cylinders were developed in 1768. Steam-powered blast furnaces could reach higher temperatures. This allowed them to use more lime in the iron-making process. With enough lime, harmful sulfur from coal or coke fuel would react with the slag (waste material) instead of contaminating the iron. Since coal and coke were cheaper and more common fuels, iron production grew a lot in the late 1700s.

From Water to Steam Power

Water power was the main source of energy before steam engines. It remained important even when steam engines became popular. However, steam engines offered many advantages that water power couldn't. They quickly became the main power source in industrial countries. For example, in the US, steam power grew from 5% to 80% of total power between 1838 and 1860.

One big benefit was the increase in power. Steam-powered mills could produce four times more power than water-powered mills. Another huge advantage was that steam engines allowed for cities to grow. Factories with steam engines could be built anywhere, not just by rivers. This meant people could work, produce goods, sell them, and live in communities that weren't tied to waterways.

Cities and towns grew around these factories. This led to local markets, rapid urbanization, better infrastructure, and easier access to materials. It also encouraged competition and specialization, and brought together more workers and money. In areas where steam power was used, population growth often increased. These steam-powered towns helped local and national economies grow, showing how vital the steam engine was.

The Steamboat

The introduction of the steamboat brought a huge period of economic growth in the United States. People like Robert Fulton, Robert Livingston, and Henry Shreve were key in bringing steamboats to America.

Around 1815, steamboats began to replace barges and flatboats for moving goods. Before steamboats, it was very hard to move goods upstream against the river current. Boats would often be built upstream, float their cargo down, and then be taken apart at the end of their journey.

With the steamboat, the transport of goods and people grew incredibly, which was key for westward expansion. Before steamboats, a trip from New Orleans to Louisville could take three to four months. With a steamboat, it was cut down to twenty-five to thirty-five days! This was great for farmers who could now sell their crops in distant markets.

Steamboats also helped with specialization. Sugar and cotton were shipped north, while goods like poultry and grain went south. Sadly, steamboats also made it easier to transport enslaved people within the country.

The rise of steamboats meant rivers needed to be improved. Natural rivers had rapids, sand bars, and shallow areas that made steamboat travel difficult. To fix this, a network of canals, locks, and dams was built. This created many new jobs along the rivers.

The economic benefits of steamboats went beyond just building the ships. They led to growth in the coal and insurance industries and created a demand for repair shops along the rivers. Overall, the steamboat made transport efficient and far-reaching, increasing the demand for goods everywhere.

Steamboats and Water Transport

After the steamboat was invented and proved successful, it quickly changed water transport. In 1814, New Orleans saw 21 steamboat arrivals. Just 20 years later, that number jumped to over 1,200! The steamboat became a major way to travel and move goods.

The transport sector grew hugely after the steam engine was used. This led to big changes in canals, steamboats, and railroads. The steamboat and canal system completely changed trade in the United States. As steamboats became popular, people became very excited about building more canals.

In 1816, the US only had 100 miles of canals. But people realized that canals were needed to connect the Mississippi–Ohio rivers with the Great Lakes to increase trade from east to west.

The Railroad

The use of steam engines on railroads was truly amazing. Now, huge amounts of goods and raw materials could be delivered to cities and factories far away. Trains could do this at a much lower cost than wagons. Railroad tracks, which were already used in mines, became the new main way to transport things after the first steam locomotive was invented.

|

| Laphonza Butler |

| Daisy Bates |

| Elizabeth Piper Ensley |