Textile industry facts for kids

The textile industry is all about designing, making, and selling textiles. These include yarn (thread), cloth, and clothing. The materials used can be natural, like cotton, or man-made using products from the chemical industry.

Contents

How Textiles Are Made

Making Cotton Fabric

| Bale breaker | Blowing room | |||||

| Willowing | ||||||

| Breaker scutcher | Batting | |||||

| Finishing scutcher | Lapping | Teasing | ||||

| Carding | Carding room | |||||

| Sliver lap | ||||||

| Combing | ||||||

| Drawing | ||||||

| Slubbing | ||||||

| Intermediate | ||||||

| Roving | Fine roving | |||||

| Mule spinning | Ring spinning | Spinning | ||||

| Reeling | Doubling | |||||

| Winding | Bundling | Bleaching | ||||

| Weaving shed | Winding | |||||

| Beaming | Cabling | |||||

| Warping | Gassing | |||||

| Sizing/slashing/dressing | Spooling | |||||

| Weaving | ||||||

| Cloth | Yarn (cheese) Bundle | Sewing thread | ||||

Cotton is the most important natural fiber in the world. In 2007, about 25 million tons of cotton were grown in over 50 countries.

Making cotton fabric involves five main steps:

- Growing and picking the cotton.

- Getting the cotton ready.

- Spinning it into yarn (thread).

- Weaving the yarn into fabric.

- Finishing the fabric to make it ready to use.

Making Man-Made Fibers

Artificial fibres are created by pushing a polymer (a type of plastic) through tiny holes called a spinneret (polymers). The fiber then hardens.

There are different ways to do this:

- Wet spinning (like for rayon) uses a liquid to make the fiber hard.

- Dry spinning (like for acetate) uses a solvent that evaporates in a hot room.

- Melt spinning (like for nylons and polyesters) cools the melted polymer with gas or air until it sets.

Some common man-made fibers are polyester, rayon, acrylic, and microfibers. These fibers can be very long, sometimes kilometers! Man-made fibers are often stronger than natural ones and can easily take on different colors from dyes. They can be used as long threads or cut into shorter pieces to be processed like natural fibers.

Using Natural Fibers

Natural fibers come from animals, plants, or even minerals.

- Animal fibers include wool from sheep, hair from goats and rabbits, and silk from silkworms.

- Plant fibers can come from the seed (like cotton), the stem (like flax, hemp, jute), or the leaf (like sisal).

All natural fibers, except silk, are short, only a few centimeters long. They have a rough surface that helps them stick together. Before they can be used, these fibers go through several steps to become clean and even.

History of Textiles

Early Textile Making

People might have known how to weave even in the Stone Age! Very old textile marks have been found in places like Moravia. In ancient Egypt (around 5000 BC), textiles were also discovered.

During Roman times, Europeans mainly wore clothes made from wool, linen, and leather. Silk, which came all the way from China on the Silk Road, was a very expensive luxury. Flax fiber has been used to make cloth in Northern Europe since ancient times.

Later, in the Middle Ages, cotton started to be brought into Northern Europe. People didn't know much about cotton, only that it was a plant. Because it felt like wool, some people even thought it came from sheep that grew on trees! By the end of the 16th century, cotton was grown in warm parts of Asia and the Americas.

The main steps to make cloth were: getting the fiber, preparing it, turning it into yarn, making yarn into cloth, and then finishing the cloth. The way fibers were prepared changed depending on the fiber. For example, flax needed to be "retted" (soaked) and "dressed," while wool needed to be "carded" (combed) and washed. But spinning and weaving were quite similar for different fibers.

Spinning started with twisting fibers by hand. Then people used a drop spindle, and later the spinning wheel. The spinning wheel was probably invented in the Islamic world around the 11th century.

Textile Industry in India

In India, the textile industry is very important for jobs, second only to farming. It provides direct work for over 35 million people. In 2010, India's textile industry was worth about US$55 billion.

India is number one in the world for jute production and has 63% of the global textile market. It's also second in global textile making, and second in silk and cotton production. Many foreign textile companies like Marks & Spencer and Zara have invested or work in India.

Textiles in Britain

At the start of the 1700s, Britain's main industry was making textiles from wool. This work employed many people across the country. Wool exports made up more than a quarter of all British exports for most of the 18th century.

The British textile industry was a big reason for the Industrial revolution. It led to new technologies, helped the coal and iron industries grow, and improved transportation. This made Britain a world leader in industry and trade.

Cotton production, mainly in Lancashire, grew very fast. Before the 17th century, most goods were made by individual workers in their homes. Goods were moved around by clothiers using packhorses. People started inventing ways to make things faster. Cotton became the most important textile, setting the stage for big changes.

Textiles in Catalonia, Spain

The cotton industry in Catalonia was the first in Spain to become industrialized. By the mid-1800s, Catalonia was Spain's main industrial region.

The industry began in Barcelona in the early 1700s, making printed cloth called chintz. This helped replace imported fabrics. The market grew quickly, especially with trade to American colonies, which provided dyes and cotton. Spinning became a big part of the industry after English spinning technology arrived around 1800.

Factories started to appear in the 1830s. At first, steam power was used, but because coal was expensive, factories later used a lot of water power from the late 1860s.

The Industrial Revolution and Textiles

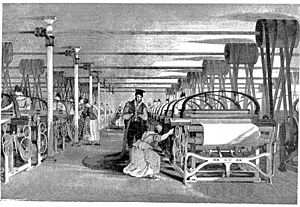

The textile industry, especially making woven fabric, grew hugely during the industrial revolution in the 1700s. Making yarn and cloth in large amounts became a major industry.

In 1734, John Kay invented the flying shuttle. This invention helped a single weaver make wider cloth much faster. Workers were worried about losing their jobs, so it took time for this new machine to be widely used. However, faster production meant more demand for spun cotton.

In 1761, the Duke of Bridgewater's canal connected Manchester to coal mines. In 1775, Matthew Boulton and James Watt started making a much better Watt steam engine.

In 1764, James Hargreaves invented the spinning jenny. This machine allowed one worker to spin many threads at once, greatly increasing production. By the time he died, over 20,000 spinning jennies were in use. Also in 1764, Thorp Mill, the world's first water-powered cotton mill, was built in Lancashire. With spinning and weaving now done by machines, cotton mills appeared all over England.

19th Century Textile Changes

With inventions like the Cartwright Loom, the Spinning Mule, and the Boulton & Watt steam engine, all the parts were in place for a machine-driven textile industry. From then on, there weren't many new inventions, but constant improvements to make things cheaper and better. Better transportation, like canals and later railways, helped bring in raw materials and send out finished cloth.

At first, water power ran the mills, then steam engines helped, and eventually, steam engines took over completely. For example, Samuel Greg built Quarry Bank Mill in Cheshire in 1784. It first used a water wheel, but steam engines were added in 1810. This mill is now a museum. It also shows how mill owners used child labor, taking orphans from nearby Manchester to work. These children were housed, fed, clothed, and given some education.

In 1830, Richard Roberts made the first loom with a cast iron frame, called the Roberts Loom. In 1842, the Lancashire Loom was made. It was a semi-automatic power loom that was used in the cotton industry for a hundred years.

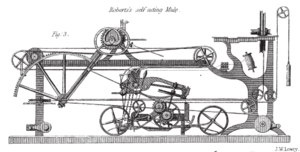

Also in 1830, Richard Roberts patented the first self-acting mule. This machine could spin thread without as much help from a worker. Before 1830, a worker could operate a mule with up to 400 spindles. After Roberts' invention, self-acting mules could have up to 1300 spindles.

| Year | 1803 | 1820 | 1829 | 1833 | 1857 |

|---|---|---|---|---|---|

| Looms | 2400 | 14650 | 55500 | 100000 | 250000 |

The industrial revolution changed how people worked and lived. Textile making, iron founding, and steam power were the three main things that caused these changes. In Britain, textile factories were mostly in Manchester and the towns around it.

Textile production in England reached its highest point in 1926. As mills closed, many of their machines were bought and used again in India.

20th Century Textile Industry

The 20th century brought huge changes to the textile industry. There were new machines, new man-made fibers, and the business became global. The old ways of doing business changed completely.

Cotton and wool were no longer the only sources for fibers. Chemical companies created new man-made fibers with better qualities for many uses. For example, rayon was invented in 1910, and DuPont's nylon in 1935. Nylon was a cheaper replacement for silk and was used for everything from stockings to military parachutes.

More and more man-made fibers were used throughout the 20th century. In the 1940s, acetate, modacrylic, and saran were developed. Acrylic, polyester, and spandex came out in the 1950s. Polyester became very popular for clothes. By the late 1970s, more polyester was sold in the United States than cotton.

By the late 1980s, making clothes was no longer the biggest market for fibers. Industrial uses and home furnishings used more. Many small companies in the United States closed in the 1970s and 1980s because of industry changes and global manufacturing.

In 2013, the biggest exporters of textiles were China ($274 billion), India ($40 billion), Italy ($36 billion), Germany ($35 billion), Bangladesh ($28 billion), and Pakistan ($27 Billion).

Textile Industry in Pakistan

The textile sector makes up 70% of Pakistan's exports. This industry contributes 8.5% to the country's total economy. Textile exports were $4.4 billion in 2017-2018. The industry employs a large number of people in Pakistan.

Pakistan is the 4th largest producer of cotton and has the third largest spinning capacity in Asia. It makes up 5% of the world's spinning capacity. There are many factories in Pakistan that produce textiles. Pakistan is also the third largest user of cotton.

Between 1947 and 2000, the number of textile mills in Pakistan grew from 3 to 600. The textile industry receives 45% of the bank loans in Pakistan.

Textile Industry in Bangladesh

Many international companies use factories in Bangladesh because the labor costs are very low. For example, a worker there might earn about 30 euros per month.

Sadly, there have been serious accidents in Bangladesh factories. In April 2013, over 1,135 textile workers died when their factory building collapsed. Other accidents have also happened due to unsafe factory conditions.

Workers in Bangladesh have also organized large strikes to ask for better pay and conditions. In 2006, tens of thousands of workers went on strike, affecting almost all 4,000 factories. In 2010, another strike led to many workers being injured.

Textile Industry in Ethiopia

Workers in Ethiopian garment factories, who make clothes for brands like Guess and H&M, earn very low monthly salaries, sometimes as low as $26. These low wages have led to workers being less productive, frequent strikes, and many workers leaving their jobs. Some factories have had to replace all their employees every 12 months on average.

A 2019 report said that the very low basic salary makes it hard for workers to live. The government and companies did not expect that workers would be unhappy with their pay and living conditions, leading to protests and people quitting.

Rules for Textile Trade

The Multi Fibre Arrangement (MFA) was a set of rules that controlled the global trade of textiles and clothes from 1974 to 2004. It set limits (called quotas) on how much developing countries could export to developed countries. It ended on January 1, 2005.

The MFA was meant to help developed countries get used to imports from developing countries. Developing countries have an advantage in textile production because it needs a lot of workers, and they have lower labor costs. Some studies said the MFA cost developing countries many jobs and billions of dollars in lost exports.

However, the MFA was not bad for all developing countries. For example, the European Union (EU) did not put limits or taxes on imports from very poor countries like Bangladesh. This helped the textile industry grow a lot there.

Later, it was decided that textile trade would be managed by the World Trade Organization (WTO). The WTO agreement slowly removed the quotas from the MFA, finishing on January 1, 2005. But many textile products still have high taxes.

Many thought Bangladesh would struggle the most after the MFA ended because of more competition, especially from China. But this didn't happen. Bangladesh's labor is still very cheap. Even though some smaller factories cut pay and laid off workers, orders for goods kept coming in. In fact, Bangladesh's exports increased by about $500 million in 2006.

Quality and Safety Rules

Just like many other products, textiles have national and international rules and standards. These help make sure that textiles are good quality, safe, and made in a way that is good for the environment.

Some important standards for textiles include:

- CPSIA, which includes rules for how easily clothing textiles catch fire.

- ASTM Textile Standards.

- REACH Regulations for Textiles.

- China Product Standard for Textiles.

See also

In Spanish: Industria textil para niños

In Spanish: Industria textil para niños

- Drapers and cloth merchants

- Textile industry in Bangladesh

- List of textile fibres

| Audre Lorde |

| John Berry Meachum |

| Ferdinand Lee Barnett |