Ceramic engineering facts for kids

Ceramic engineering is a cool field that combines science and technology to create amazing objects from special materials. These materials are not metals and are not made from living things. They are usually made by heating them up a lot, or sometimes by using special chemical reactions at lower temperatures.

This field covers everything from cleaning the raw materials, making the right chemical mixes, shaping them into useful parts, and then studying what they are made of and how strong they are.

Ceramic materials can have a very organized, crystal-like structure, or they can be more like glass, with a less organized structure. They can be made by cooling down melted material, by heating and shaping them, or by using special chemical methods at lower temperatures.

Because ceramics can handle a lot of heat, they are used in many places where metals or plastics just wouldn't work. You can find ceramic materials in mining, airplanes, medicine, electronics, and even in things like packaging and power lines!

Contents

History of Ceramics

The word "ceramic" comes from an old Greek word, keramikos, which means "pottery." It's also linked to an even older word meaning "to burn." So, ceramics is all about making things from ceramic materials. Ceramic engineering, like many sciences, grew from different ideas over time. Today, it's often studied alongside materials science.

Here are some important moments in ceramic history:

- In 1709, Abraham Darby in England used a special fuel called coke to make metal smelting better. Coke is now used to make strong carbide ceramics.

- The famous potter Josiah Wedgwood opened the first modern ceramics factory in England in 1759.

- In 1888, Austrian chemist Carl Josef Bayer found a way to get pure alumina from bauxite ore. This "Bayer process" is still used today for ceramics and aluminum.

- Around 1880, brothers Pierre Curie and Jacques Curie discovered piezoelectricity in a special salt. This property is super important for electroceramics, which are ceramics used in electronics.

- In 1893, Edward Goodrich Acheson mixed coke and clay and heated them up to create carborundum, also known as synthetic silicon carbide. Around the same time, Henri Moissan also made silicon carbide and tungsten carbide in his electric furnace in Paris.

- In 1923, Karl Schröter in Germany found a way to "glue" tungsten carbide particles together with cobalt. These "cemented carbides" make cutting tools much stronger.

- In the 1920s, Walther Nernst developed cubic-stabilized zirconia in Berlin. This material is used in car exhaust systems to sense oxygen.

One main challenge with ceramics is that they can be brittle, meaning they can break easily.

Ceramics in the Military

During World War II, the military needed very strong materials. This pushed scientists to develop new and better ceramics. In the 1960s and 1970s, even more new ceramics were created for things like atomic energy, electronics, communication, and space travel. When ceramic superconductors were found in 1986, it led to lots of research into using them for electronic devices and electric motors.

The military also needs strong, clear materials for transparent armour. This armor needs to be see-through but also protect against bullets and explosions. It also needs to work with night vision equipment. Scientists are always looking for new materials that are thinner, lighter, and offer even better protection.

These special ceramic parts are used in many optical and electronic devices, such as:

- Optical fibres for sending light signals.

- Optical switches and laser amplifiers.

- Lenses for different devices.

- Materials for solid-state lasers.

- Windows for gas lasers.

- Infrared (IR) heat seeking devices for missile guidance and IR night vision.

Modern Ceramic Uses

Today, ceramic engineering is a huge industry worth billions of dollars. Scientists are always finding new ways to use ceramics.

- Ceramic knives made from zirconium dioxide stay sharp much longer than steel knives. But be careful, they can break if dropped on a hard surface.

- Ceramics like alumina, boron carbide, and silicon carbide are used in bulletproof vests. These "ballistic plates" can stop bullets from small guns. They are also used to protect cockpits in some military planes because they are light.

- Silicon nitride is used in ceramic ball bearings. They are much harder than metal bearings, so they last longer and can spin faster. They also don't rust and can be used in wet places. The main downside is that they cost a lot more.

- In the 1980s, Toyota explored making a ceramic engine that could run super hot (over 3300°C). Ceramic engines wouldn't need a cooling system, making them lighter and more fuel-efficient. However, making ceramic parts with enough precision and strength for mass production is still very difficult.

- Scientists are also working on ceramic parts for gas turbine engines. If turbine engines could use ceramics, they could run more efficiently, allowing planes to fly farther or carry more fuel.

- Recently, there have been big steps forward in bio-ceramics, like those used for dental implants and artificial bones. A natural mineral in bone, hydroxyapatite, can be made in a lab and formed into ceramic materials. Implants made from these materials can connect well with real bone and tissues without causing problems. They are often used to coat metal implants or as bone fillers. Scientists are even working on making strong, solid hydroxyapatite ceramics to replace metal and plastic in weight-bearing bone implants. Eventually, these ceramics might be used as full bone replacements or even as synthetic bones when combined with proteins.

- Special ceramic materials that contain actinides (radioactive elements) are used in nuclear fuels. They can also be used as safe sources of radiation for powering unmanned space vehicles or small electronic devices. These ceramics help keep radioactive waste safely contained.

Glass-Ceramics

Glass-ceramics are special materials that are a mix of both glass and ceramics. They have some parts that are like glass and some parts that are crystal-like. They are made by carefully heating glass so that some of it turns into crystals. This process is usually avoided when making regular glass.

Glass-ceramics often have a lot of crystalline parts, sometimes up to 90% of their volume. This gives them interesting properties, especially how they react to heat.

To make glass-ceramics, melted glass is slowly cooled down. Then, it's heated again in a controlled way. Sometimes, special "nucleation agents" are added to help control how the crystals form. Unlike many ceramics, glass-ceramics usually don't have many tiny holes inside them.

A common type of glass-ceramic is made from lithium and aluminosilicate. These materials are amazing because they are not affected by sudden temperature changes. This makes them perfect for things like stovetops. The way they are made allows the expansion from heat in the glass part to be balanced by the contraction in the crystal part. This means the material barely changes size, even with quick temperature changes up to 1000°C!

How Ceramics Are Made

Making traditional ceramics usually follows these steps:

- Milling: This is like grinding. It's the process of breaking down large pieces of material into smaller ones. This can involve just breaking up clumps or grinding the particles themselves. It's often done with machines that crush, impact, or rub the materials together. A ball mill is an example, where media tumble and break the material.

- Batching: This is simply weighing out the right amounts of different raw materials, like a recipe, to get them ready for mixing.

- Mixing: After batching, the materials are mixed together. This can be done dry or wet, using different types of mixers, like those similar to cement mixers.

- Forming: This is where the mixed material is shaped into its final form. This can be done by:

* Extrusion: Pushing the material through a shaped opening, like making bricks. * Pressing: Squeezing the material into a mold to make shaped parts. * Slip casting: Pouring a liquid mixture into a mold, like making toilet bowls or statues. The shaped material at this stage is called a "green" part. It's soft and can easily change shape if handled roughly.

- Drying: Next, any water or other liquids are removed from the "green" part. Spray drying is often used for powders. This step needs to be done carefully, as heating too fast can cause cracks. The dried part is smaller and very brittle.

- Sintering: This is a very important step where the dried parts are heated in a kiln to a very high temperature, but below their melting point. During this "firing" process, the materials chemically change, bonding together and becoming denser and stronger. The fired part will be even smaller than the dried part.

Shaping Ceramics

There are many ways to shape ceramic powders into complex objects. These methods are important for making advanced parts like those used in high-temperature engines and turbines. Besides ceramics, other materials like wood, metal, or water might be used in the shaping process, but they are removed later when the ceramic is fired.

Some common ways to shape ceramics include:

- Throwing: Like on a potter's wheel.

- Slipcasting: Pouring a liquid ceramic mixture into a mold.

- Tape casting: Making thin, flat sheets of ceramic.

- Injection molding: Injecting melted ceramic material into a mold.

- Dry pressing: Compressing dry ceramic powder in a mold.

- Isostatic pressing: Applying pressure evenly from all directions.

- Hot isostatic pressing (HIP): Applying heat and pressure at the same time.

- 3D printing: Building ceramic objects layer by layer.

These methods help create ceramic parts that are very precise, have smooth surfaces, are very dense, and are uniform inside.

The Sintering Process

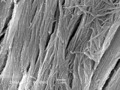

The idea behind sintering is simple: you bake the ceramic. After a "green body" (the roughly shaped object) is made, it's put into a kiln and heated. The temperature is below the point where the ceramic would melt. During this heating, tiny particles in the ceramic move around and bond together. This makes the material denser and stronger, and any tiny holes inside the object start to close up.

Another big change during sintering is that the material becomes polycrystalline, meaning it's made of many tiny crystals or "grains." These grains grow larger during sintering, and their size affects how strong the final ceramic is.

There are many ways to improve the sintering process. Sometimes, the "green body" is pressed before firing to make it denser from the start. Sometimes, special organic "binders" (like glue) are added to hold the green body together; these burn away during firing. Lubricants can also be added during pressing to help with densification.

Instead of a dry powder, a liquid mixture (called a slurry) can be used and then cast into a shape, dried, and sintered. This is how traditional pottery is often made. If different materials are mixed, sometimes one of them melts during sintering. This "liquid phase sintering" can make the process faster.

Ceramic Composites

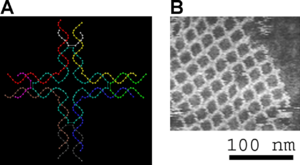

Scientists are very interested in making ceramic composites. These are materials made by combining two or more different ceramic materials. Usually, there's a main ceramic material (the matrix) and another ceramic material mixed in as particles, whiskers (tiny fibers), or longer fibers. The challenge is to mix them perfectly so they are spread out evenly.

One popular material for composites is tetragonal zirconia. It can make ceramics much tougher because it changes its crystal structure under stress. Other hard materials like silicon carbide, boron carbide, and tungsten carbide are also added to ceramics like alumina to make them stronger.

When making these composites, it's important to control not only how evenly the different materials are mixed but also the size of the grains in the main ceramic. Composites generally resist damage and breaking better, but they still need to be made very carefully to work well.

One good way to make particulate composites is to coat tiny particles of one ceramic with another ceramic. This helps to get a very even mix and can make the composite perform better.

Sometimes, composites can be made by melting materials and then letting them solidify. Or, by using special methods like chemical vapour infiltration, where gases react to form the ceramic matrix around fibers.

For fiber composites, two main things are needed: cheaper fibers and ways to protect the fibers from damage when exposed to high temperatures and oxygen.

Applications of Ceramics

Technical ceramics are used in many advanced products:

- Tiles on the Space Shuttle to protect it from extreme heat.

- Gas burner nozzles.

- Bulletproof vests.

- Uranium oxide pellets for nuclear fuel.

- Medical implants in the body.

- Jet engine turbine blades.

- Missile nose cones.

These products are often made from special materials chosen for their unique properties, not just clay. They can be:

- Oxides: Like silica, alumina, zirconia.

- Non-oxides: Like carbides, borides, nitrides, silicides.

- Composites: Mixtures of different ceramics, or ceramics with other materials.

Ceramics are used in many high-tech industries. Besides the uses listed above, they are also used as coatings. For example, a ceramic coating on a titanium airplane frame can protect it. The field of ceramic engineering is always growing, now including studies of single crystals and glass fibers, not just traditional ceramics.

Aerospace Uses

- Engines: Protecting hot aircraft engines from damaging other parts.

- Airframes: Used as strong, lightweight parts that can handle high temperatures.

- Missile nose-cones: Protecting the inside of missiles from heat.

- Space Shuttle tiles: For heat protection during re-entry.

- Space-debris ballistic shields: Ceramic fiber shields offer better protection against fast-moving space debris than aluminum shields of the same weight.

- Rocket nozzles: Directing the super-hot exhaust gases from rockets.

- Unmanned Air Vehicles (UAVs): Using ceramic engines in drones can make them perform better and cost less to operate.

Biomedical Uses

- Artificial bone and parts for dentistry, like teeth.

- Biodegradable splints and materials to help strengthen bones.

- Materials for implants in the body.

Electronics Uses

- Capacitors (store electrical energy).

- Integrated circuit packages (protect computer chips).

- Transducers (change one type of energy to another, like sound to electricity).

- Insulators (stop electricity from flowing).

Optical Uses

- Optical fibres for sending light signals.

- Switches for light.

- Laser amplifiers (make laser light stronger).

- Lenses for cameras and other devices.

- Infrared heat-seeking devices.

Automotive Uses

- Heat shields in cars.

- Exhaust heat management to control heat from the engine.

Biomaterials

Nature is full of amazing examples of how living things create strong materials, often using silica (like glass). These natural materials, like bone or shells, are incredibly strong and organized in complex ways. They form at low temperatures and neutral pH, unlike many man-made ceramics. Living organisms control exactly how these minerals form, making them very precise.

Most natural materials are complex mixtures that are surprisingly strong, even though they are made from simple parts. Scientists are studying these natural designs to create new, super-strong materials. They are looking at how nature builds things in layers and how materials can even repair themselves.

The basic building blocks are things like amino acids, which form proteins. These proteins are the main parts of "soft tissues" in many natural minerals. The "hard" parts are often strengthened by minerals like hydroxyapatite (in bone), silica, and aragonite (in shells). Scientists are studying how the tiny structures of these natural materials affect their strength.

Nature shows us that inorganic materials can be created at normal temperatures and pressures, yet still form incredibly precise and complex structures. Understanding how living things control the growth of minerals like silica could lead to big breakthroughs in materials science and new ways to make tiny, strong composite materials.

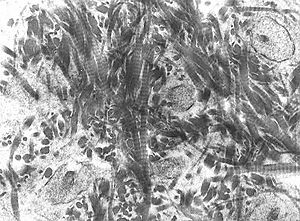

For example, scientists have closely studied the inside of an abalone shell, called nacre or mother-of-pearl. These shells are known to be some of the strongest non-metallic materials. Pictures show neat layers of mineral "tiles" separated by thin organic sheets. This layered structure, with different features at different sizes, is what scientists call a "hierarchical composite structure."

Future developments in ceramics will likely involve making materials inspired by nature. This means using processes like "self-assembly," where tiny parts organize themselves, and creating materials with complex, layered structures like those found in living things.

See also

In Spanish: Cerámica técnica para niños

In Spanish: Cerámica técnica para niños

- Ceramic matrix composite

- Chemical engineering

- Colloid

- Glass-ceramic-to-metal seals

- Materials science

- Mechanical engineering

- Nanoparticle

- Photonic crystal

- Quenching

- Three-point flexural test

- Transparent materials

- Yttria-stabilized zirconia

Images for kids

-

Scanning electron microscopy image of bone

| Stephanie Wilson |

| Charles Bolden |

| Ronald McNair |

| Frederick D. Gregory |