Sucrose facts for kids

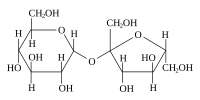

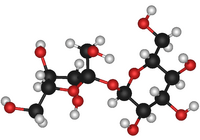

Sucrose is what we commonly call table sugar. It's also known as saccharose. This sweet substance is a type of carbohydrate called a disaccharide. This means it's made from two simpler sugars joined together: glucose and fructose.

The chemical formula for sucrose is C12H22O11. Plants create sucrose, and it's a very important part of what humans eat.

| Sucrose | |

|---|---|

| General | |

| Systematic name | Sucrose |

| Other names | Sugar, Saccharose |

| atomic formula | C12H22O11 |

| SMILES | OC1C(OC(CO)C(O)C1O) OC2(CO)OC(CO)C(O)C2O |

| Molar mass | 342.29648 g/mol |

| Appearance | white solid |

| CAS number | [57-50-01] |

| Chemical Properties | |

| Density and phase | 1.587 g/cm³, solid |

| Solubility in water | 211.5 g/100 ml (25°C) |

| Melting point | 186°C (459.15 K) |

| Boiling point | decomposition |

| Chiral rotation [α]D | +66.47° |

| Refractive index | 1.5376 |

| Structure | |

| Molecular shape | ? |

| Crystal structure | monoclinic hemihedral |

| Dipole moment | ? D |

| Hazards | |

| MSDS | External MSDS |

| Main hazards | Combustible |

| NFPA 704 | |

| Flash point | N/A |

| R/S statement | R: ? S: ? |

| RTECS number | WN6500000 |

| Supplementary data page | |

| Structure and properties |

n, εr, etc. |

| Thermodynamic data |

Phase behaviour Solid, liquid, gas |

| Spectral data | UV, IR, NMR, MS |

| Related compounds | |

| Other anions | ? |

| Other cations | ? |

| Except where noted otherwise, data are given for materials in their standard state (at 25°C, 100 kPa) Infobox disclaimer and references |

|

| Solubility of Pure Sucrose | |

|---|---|

| Temperature(C) | g sucrose/g water |

| 50 | 2.59 |

| 55 | 2.73 |

| 60 | 2.89 |

| 65 | 3.06 |

| 70 | 3.25 |

| 75 | 3.46 |

| 80 | 3.69 |

| 85 | 3.94 |

| 90 | 4.20 |

Contents

What is Sucrose?

Pure sucrose is usually a fine, white, and odorless powder. It has a very pleasant, sweet taste. This is why it's so popular in foods and drinks!

How Table Sugar is Made

History of Sugar Production

Making table sugar has a long and interesting history. Some experts believe people in India first learned how to make sugar crystals around 350 AD. Ancient Chinese writings from the 8th century BC also mention sugar cane, saying they learned about it from India.

Around 500 BC, people in India started making sugar syrup. They would cool it in large bowls to create raw sugar crystals. These crystals were easier to store and move around. The local Indian word for these crystals was khanda, which is where our word candy comes from!

When Alexander the Great's army was in India, they saw people growing sugar cane. They were making a "granulated, salt-like sweet powder." This was called sākhar locally, which became sakcharon in Greek. The Greek soldiers took some of these "honey-bearing reeds" back home.

For over a thousand years, sugar cane was a rare crop. Sugar was a very special item, and sugar traders became very rich. Venice, a powerful city in Europe, was the main place for distributing sugar. Arabs also started growing it in Sicily and Spain.

After the Crusades, sugar became more popular in Europe, competing with honey as a sweetener. The Spanish began growing sugar cane in the West Indies in 1506. The Portuguese started growing it in Brazil in 1532.

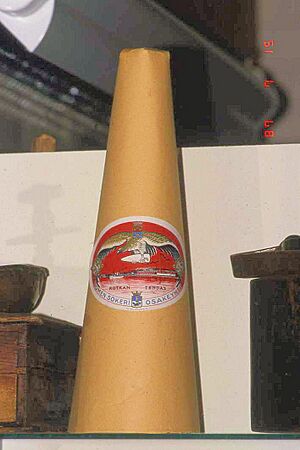

Until the 18th century, sugar was a luxury that only wealthy people could afford. But in the 18th century, the demand for table sugar grew a lot in Europe. By the 19th century, it was seen as something everyone needed. People started using sugar in tea, cakes, confectionery, and chocolates. Sugar was sold in new ways, like solid cones. People needed a special tool, called a sugar nip, to break off pieces.

The high demand for cheaper table sugar led to the colonization of tropical islands and nations. These places were perfect for growing sugar cane and making table sugar. Growing sugar cane and working in sugar mills was very hard and inhumane work. The need for cheap labor for this work led to the slave trade from Africa. Later, it led to people from South Asia working under contracts. Millions of people were brought to places like the Caribbean and South America. The mix of different cultures in many nations today was influenced by the history of table sugar.

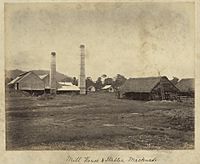

In the late 1700s, sugar production became more mechanized. The steam engine was first used in a sugar mill in Jamaica in 1768. Soon, steam replaced direct fire for heating. During this time, Europeans also started trying to make sugar from other plants. A scientist named Andreas Sigismund Marggraf found sucrose in beet root. His student, Franz Achard, built a sugar beet factory in Prussia. The beet-sugar industry really grew during the Napoleonic Wars. This was when France and other European countries couldn't get sugar from the Caribbean. By 2010, about 20% of the world's sugar came from beets.

Today, a large beet refinery can produce about 1,500 tonnes of sugar a day. It needs about 150 workers for 24-hour production.

Modern Sugar Production

Table sugar comes from plants. The two main sugar crops are sugarcane and sugar beets. Sugar can make up 12% to 20% of these plants' dry weight. Other plants that produce sugar include the date palm, sorghum, and the sugar maple.

To get sucrose, these crops are soaked in hot water. The liquid is then made thicker to create syrups. From these syrups, solid sucrose crystals can be formed. In 2017, the world produced 185 million tonnes of table sugar.

Most cane sugar comes from countries with warm climates because sugarcane cannot handle frost. Sugar beets, however, grow best in cooler areas and don't like extreme heat. About 80% of sucrose comes from sugarcane, and most of the rest comes from sugar beets.

In mid-2018, India and Brazil produced the most sugar, each with about 34 million tonnes. The European Union, Thailand, and China were also big producers. India, the European Union, and China were the top consumers of sugar in 2018.

Beet sugar comes from cooler regions like northwest and eastern Europe, northern Japan, and parts of the United States. In the northern hemisphere, the beet harvest usually starts around September and can continue until March.

Types of Sugar

Cane Sugar

Since the 6th century BC, sugar cane producers have crushed the harvested cane to get its juice. They then clean the juice, often using lime. Boiling the juice helps remove impurities. As the liquid cools, it is stirred to form sugar crystals. Machines called centrifuges then separate the crystals from the syrup. The sugar can then be sold or processed further to make lighter types of sugar.

Brazil is a major producer of sugarcane and its products, like crystallized sugar and ethanol (alcohol fuel).

Beet Sugar

Beet sugar producers first slice washed beets. Then, they use hot water to get the sugar out in a "diffuser". An alkaline solution helps remove impurities. After filtering, the juice is made thicker by evaporation until it's about 70% solids. Then, sugar crystals are formed in a controlled way. A centrifuge separates the sugar crystals from the liquid. This liquid is reused in the crystallization process. When no more sugar can be removed, the remaining liquid is called molasses. This molasses is often used for animal feed or industrial purposes.

The white sugar is then sieved to create different sizes for sale.

Cane vs. Beet Sugar

It's hard to tell the difference between refined sugar made from beet and cane. One way is to check the carbon isotopes. Cane sugar and beet sugar have different ratios of 13C and 12C isotopes. This test helps detect fraud or check if fruit juice has been mixed with other things.

Sugar cane grows better in hot climates, but it needs about four times more water than sugar beet. Because of this, some countries that traditionally grew cane sugar, like Egypt, have built new beet sugar factories since 2008. Some sugar factories even process both sugar cane and sugar beets.

The leftover materials from sugar production are different depending on the plant used. Cane molasses is often used in food. However, molasses from sugar beets is not usually eaten by humans. It's mostly used for industrial fermentation (like making alcohol) or as animal feed. Both types of dried molasses can also be used as fuel.

Pure beet sugar is not always clearly labeled in stores. Many store brands or "private label" sugar products are actually pure beet sugar. You can sometimes identify beet sugar by looking at the lot code on the package, if you know what the codes mean.

Culinary Sugars

Mill White Sugar

Mill white sugar, also called plantation white or crystal sugar, is made from raw sugar. It is treated to reduce its color and stop it from getting darker during the crystallization process. This type of sugar is common in sugarcane-growing areas. However, it doesn't store or ship well. After a few weeks, it can become discolored and clump together. So, it's usually sold and used locally.

Blanco Directo Sugar

Blanco directo is a white sugar common in India and other South Asian countries. It's made by removing many impurities from cane juice. This sugar is purer than mill white sugar but not as pure as white refined sugar.

White Refined Sugar

White refined sugar is the most common type of sugar in North America and Europe. It's made by dissolving and cleaning raw sugar. This can be done using different methods, including filtration. It's then cleaned even more by filtering it through activated carbon or bone char. Beet sugar factories produce refined white sugar directly.

White refined sugar is usually sold as granulated sugar. It's dried to stop it from clumping and comes in different crystal sizes for home and industrial use:

- Coarse-grain sugar, like sanding sugar or "pearl sugar," has large crystals. It's used to add sparkle and flavor to baked goods and candies. Its crystals won't dissolve when heated.

- Granulated sugar is what we know as table sugar. Its grains are about 0.5 mm across. "Sugar cubes" are lumps of granulated sugar mixed with syrup, made for easy use.

- Caster sugar (0.35 mm) is a very fine sugar. It's named because its grains are small enough to fit through a sugar caster, a small shaker used to sprinkle sugar. It's often used in baking and drinks because it dissolves faster than regular white sugar. You can make caster sugar at home by grinding granulated sugar.

- Powdered sugar, also called confectioner's sugar or icing sugar, is made by grinding sugar into a fine powder. Manufacturers might add a small amount of anticaking agent like cornstarch to prevent it from clumping.

Brown sugar comes from the later stages of cane sugar refining. It has fine crystals with a lot of molasses in it. Or, it can be made by coating white refined sugar with molasses syrup. Brown sugar's color and taste get stronger with more molasses. It also holds moisture better. Brown sugars can harden if left out, but you can usually make them soft again.

High-Fructose Corn Syrup

High-fructose corn syrup (HFCS) is a sweetener that is often cheaper to use in food and drink manufacturing than refined sucrose. Because of this, HFCS and other natural sweeteners have partly replaced sucrose in many foods made in the U.S.

Some people in the media have said that HFCS is unhealthy. However, medical experts and the United States Food and Drug Administration (FDA) say that "Sucrose, HFCS, invert sugar, honey, and many fruits and juices deliver the same sugars in the same ratios to the same tissues within the same time frame to the same metabolic pathways." This means your body processes them in similar ways.

While scientists agree that all dietary sugars can lead to health problems if eaten too much, the idea that HFCS is especially unhealthy is not supported by scientific evidence. Health authorities and the FDA recommend that everyone should limit how much sugar-based sweeteners they eat overall.

See also

In Spanish: Sacarosa para niños

In Spanish: Sacarosa para niños

| Emma Amos |

| Edward Mitchell Bannister |

| Larry D. Alexander |

| Ernie Barnes |