History of silk facts for kids

Silk making started in China way back in the Neolithic period, about 6,000 years ago. For a long time, China was the only place that knew how to make silk. This secret was kept safe until the Silk Road opened around 114 BC. Even then, China held a strong control over silk production for another thousand years.

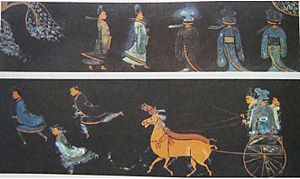

Silk wasn't just for clothes in China. It was also used for writing and other things. The color of silk worn even showed a person's social class during the Tang dynasty.

Around 300 AD, silk farming reached Japan. By 552 AD, the Byzantine Empire got silkworm eggs and started making silk. The Arabs also began silk production around the same time. This spread of silk making meant China's silk exports became less vital. However, Chinese silk still ruled the market for fancy silks.

The Crusades helped bring silk production to Western Europe. Many Italian states saw a big economic boost from selling silk across Europe. New ways of making silk also appeared in Europe during the Middle Ages. The spinning wheel was one important invention. By the 16th century, France joined Italy in having a successful silk trade.

The Industrial Revolution changed Europe's silk industry a lot. Making cotton became much cheaper, so many factories focused on cotton. Silk production, which was more costly, became smaller. But new weaving machines, like the Jacquard loom, made silk cloth production more efficient. This loom could create very detailed designs. Sadly, a disease affecting silkworms caused production to drop, especially in France.

In the 20th century, Japan and China became the top silk producers again. China is now the world's biggest silk maker. New man-made fabrics like nylon and polyester are cheaper and easier to care for. This has made silk less common. Today, silk is mostly seen as a luxury item, not as important as it once was.

Contents

How Silk Began

Early Discoveries of Silk

The oldest signs of silk are over 8,500 years old. They were found in ancient tombs in Jiahu, China. Scientists found proof of silk fibers in these tombs. Simple weaving tools and bone needles were also found. This suggests people in Jiahu might have known how to weave and sew.

Other silk evidence comes from the Yangshao culture in Xia County, Shanxi. A silkworm cocoon, cut in half, was found there. It dates back to between 4000 and 3000 BC. This silkworm was identified as Bombyx mori, the type we use today. Parts of an early loom were also found in Zhejiang, from about 4000 BC.

The oldest piece of woven silk fabric is from 3630 BC. It was used to wrap a child's body in Henan, China. Similar silk remains were found in another site in Henan in 2019. Small pieces of silk were also found in Zhejiang, dating to 2700 BC. More fragments have been found in royal tombs from the Shang dynasty (around 1600–1046 BC).

Later, the secret of silk making spread outside China. People in Korea, Japan, and India learned how to raise silkworms and make silk fabric. The Old Testament mentions silk, showing it was known in Western Asia long ago. Experts believe China started trading silk to the West around the 2nd century BC. For example, the Persian king Darius III used silk.

Even though silk spread quickly across Asia and Europe, China kept its silk production secret for 3,000 years. The earliest silk outside China was found in the Indus Valley civilisation. These silk threads, from 2450–2000 BC, show signs of reeling and silk farming.

Myths and Legends of Silk

Many stories and legends tell how silk making began. One famous Chinese legend is about Empress Leizu. Around 3000 BC, a silkworm cocoon supposedly fell into her teacup. The 14-year-old empress tried to pull it out and saw a long, strong thread. She then gathered more cocoons and wove them into cloth.

Her husband, the Yellow Emperor, asked her to study the silkworm's life. She then taught others how to raise silkworms. Because of this, she became known as the goddess of silk in Chinese mythology.

The knowledge of silk production eventually left China. One story says a Chinese princess, marrying a prince of Khotan around the 1st century AD, smuggled silkworm eggs out. She loved silk and didn't want to go without it. This broke the imperial rule against exporting silkworms.

Even though China exported a lot of silk, they kept the secret of how to make it. So, other cultures made up their own stories. In ancient Rome, many people thought the Chinese got silk from tree leaves. The writer Pliny the Elder was one of the few who knew the truth. He wrote that the Bombyx (silk moth) "weave webs, like spiders, that become a luxurious clothing material for women, called silk."

Silk in Ancient and Medieval China

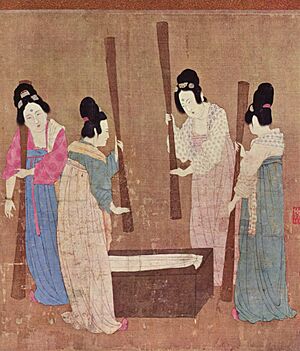

In China, silkworm farming was first done by women. Many women worked in the silk industry. Silk became so popular among the rich that rules were made to limit its use. Only the emperor and his family were allowed to wear it at first.

For about a thousand years, only the emperor and top officials could wear silk. Silk was a sign of great wealth because of its shiny look. This shine comes from the silk fiber's special structure, which reflects light. Over time, other noble classes in China also started wearing silk.

Silk was also used for decorations and other things. It was used in musical instruments, for fishing, and even in bow-making. However, ordinary farmers were not allowed to wear silk until the Qing dynasty (1644–1911).

Paper was a major invention in ancient China. From the 3rd century BC, paper was made from many materials, including silk. Silk paper became the first type of luxury paper. Researchers found early writing on silk paper in a tomb from around 168 BC. This silk paper was more expensive but easier to use than bamboo strips. Many important writings, like maps and medical texts, were found on silk.

During the Han dynasty, silk became very valuable. It was used to pay government officials and reward worthy citizens. Like gold, silk cloth became a form of money in China, alongside bronze coins.

Neighboring countries were jealous of China's silk wealth. The Xiongnu people often attacked Chinese provinces for silk for about 250 years. Silk was often given by the emperor to these tribes to keep peace.

Silk is mentioned in ancient Chinese texts, showing how important it was. For over a thousand years, silk was the main diplomatic gift from the Chinese emperor. The Chinese character for silk (糸) even became a basic part of many other Chinese words.

The use of silk in clothing was strictly controlled in China. During the Tang dynasty and Song dynasty, different silk colors showed the rank of officials. Only the highest classes could wear certain colors. Under the Ming dynasty, silk was used for many accessories. These included handkerchiefs, wallets, and belts. They often had embroidered animals or designs. These fashion items also showed a person's status.

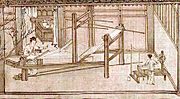

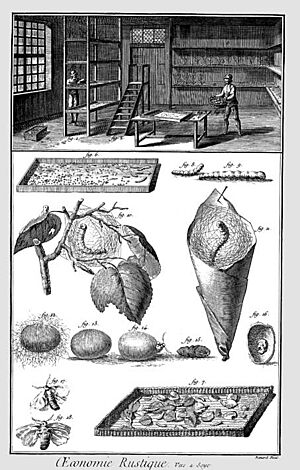

- Chinese silk making process

The Silk Road and Trade

Archaeological finds show that silk was a prized luxury item in other countries long before the Silk Road opened. For example, silk was found in an ancient tomb in Egypt, dating back to 1070 BC.

The Greeks and Romans called the Chinese the Seres, meaning "people of silk." Some historians say the first Roman encounter with silk was at the Battle of Carrhae. Roman soldiers were amazed by the shiny silk banners of their enemies and fled.

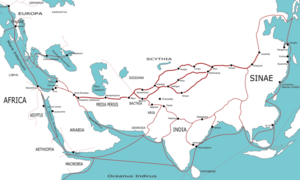

The Silk Road to the west was opened by the Chinese in the 2nd century AD. The main route started from Xi'an, going through deserts and mountains. Caravans of 100 to 500 people, with camels and yaks, carried goods. They traveled for about a year to reach the Mediterranean coast. Another southern route went through Yemen, Burma, and India.

After Rome conquered Egypt in 30 BC, trade with Asia grew. Romans loved silk cloth from the Far East. The Roman Senate tried to ban silk because it was so expensive and seen as a sign of decadence. Importing Chinese silk caused a lot of gold to leave Rome.

China traded silk, teas, and porcelain. India traded spices, ivory, and jewels. The Roman Empire exported gold, silver, and glassware. The "Silk Road" wasn't one continuous road. Goods were traded by many merchants along different parts of the route. Indian, Bactrian, and later Sogdian, Arab, and Persian traders were key players.

Later, sea trade grew, and land routes of the Silk Road became less important. But the Silk Road was vital for the growth of many civilizations. Besides silk, other goods like perfumes, medicines, and even rhubarb were traded. Ideas, religions, and even diseases like the bubonic plague also traveled along these routes.

Silk Spreads Globally

China kept its silk production a secret for centuries. An imperial law even made it punishable by death to export silkworms or their eggs. However, silk making reached Japan around 300 AD. Japanese students visiting China brought back the knowledge. Later, more diplomatic exchanges helped spread silk techniques in Japan.

From the 4th century BC, silk reached the Hellenistic world through merchants. They traded silk for gold, ivory, and horses. Silk became a way to measure the value of goods. Hellenistic Greece tried to grow mulberry trees and raise silkworms. Sassanid Persia controlled the silk trade to Europe. The Greek word for silk, serikos, came from Seres, their name for the Chinese. This word eventually led to the English word "silk."

A story by Procopius says that in 552 AD, the Byzantine emperor Justinian finally got silkworm eggs. He sent two monks to Central Asia. They smuggled silkworm eggs in hollow bamboo rods. The eggs hatched, and the Byzantine Empire started its own silk industry. This allowed them to make silk fabrics for the emperor.

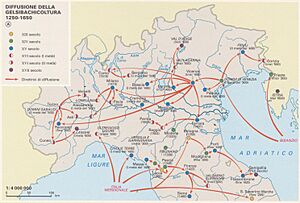

The Arabs, through their conquests, spread silk farming across the Mediterranean. This led to silk production in North Africa, Spain, and Southern Italy. By the late 9th century, mulberry trees were grown in southern Italy for silk.

Catanzaro, in Calabria, Italy, was the first place to make silk in Italy. This was between the 9th and 11th centuries. For centuries, Catanzaro silk was sold across Europe. The city became famous for its fine silks, velvets, and brocades. At one point, silk from Calabria made up 50% of all Italian and European silk.

Even though China lost its monopoly, it became a major silk supplier again during the Tang dynasty. They industrialized silk production during the Song dynasty. China continued to export high-quality silk to Europe. However, after the Crusades, silk production techniques spread across Western Europe.

In 1147, Norman King Roger II of Sicily attacked Byzantine silk centers in Greece. He took the silk workers and their equipment to Palermo and Calabria. This helped the Norman silk industry grow. The sack of Constantinople in 1204 also caused many silk artisans to leave the city. Italy then developed a large silk industry. Many skilled weavers from Constantinople settled in Italy.

The silk industry boomed in Lucca, Italy, in the 11th and 12th centuries. This was due to many immigrants. As imports of Chinese silk decreased, Italian cities like Lucca, Genoa, Venice, and Florence increased their own silk production. By 1472, Florence had 84 silk workshops and 7,000 craftsmen.

In 1519, Emperor Charles V recognized Catanzaro's silk industry. He allowed the city to create a silk guild to control production. By 1660, Catanzaro had 1,000 looms and employed 5,000 people. Its silk was sold across Italy, France, Spain, and England.

Silk in Medieval Europe

During the high Middle Ages (1000–1250 AD), silk making techniques stayed mostly the same. But between the 10th and 12th centuries, small changes appeared. Then, in the 13th century, bigger changes led to new fabrics. Silk remained rare and expensive. However, better technology meant more silk could be produced. Byzantine centers in Greece and Syria, and Arab centers in Sicily and Spain, supplied more luxury silk.

New Silk Production Technology

The 13th century saw improvements in silk production technology. Early forms of machines to process silk yarns were used. These machines were perfected in Bologna, Italy, around 1270–1280.

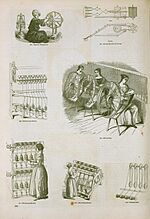

From the 14th century, complex weaving machines were used. The earliest picture of a European spinning wheel is from a stained glass window in the Cathedral of Chartres. Other machines for preparing silk threads also appeared. It's thought that some of these inventions came from the silk industry.

By the late 14th century, cheaper production methods became common. This was partly due to the Black Death. In the silk industry, water-powered mills became more popular.

In the late 15th century, a new type of loom was brought to France by an Italian weaver. This machine could work yarns faster and more accurately. Further improvements were made to looms throughout the century.

Silk in France

Italian silk was very expensive. French fashion needed lighter and cheaper materials. So, these materials started to be made locally in France. But Italian silk remained highly valued for furniture and its bright colors.

Following the example of rich Italian cities, Lyon in France became a center for silk. In 1466, King Louis XI wanted to build a French silk industry in Lyon. He brought many Italian workers, especially from Calabria. The skilled weavers from Catanzaro taught their techniques in Lyon.

Despite protests, Louis XI moved some silk production to Tours. His goal was to reduce France's trade debt with Italy. Later, under Francis I around 1535, a royal charter allowed two merchants to develop silk trade in Lyon. In 1540, Lyon got a monopoly on silk production.

From the 16th century, Lyon became the capital of European silk trade. Its silks started to have their own unique style, moving away from Oriental designs. Thousands of workers, called canuts, worked in this booming industry. By the mid-17th century, over 14,000 looms were used in Lyon. The silk industry supported a third of the city's population.

In the 18th and 19th centuries, Provence also saw a silk farming boom. Much of this silk was sent to Lyon. Many people worked from home, spinning and treating silk. This increased their income.

Silk in Modern Times

The Industrial Revolution and Silk

The Industrial Revolution brought huge changes to the textile industry. New machines were invented, especially for cotton. Silk production, however, didn't benefit as much from early spinning inventions. Silk didn't need spinning in the same way. Making fancy silk fabrics with gold and silver threads was also very complex.

In the 17th and 18th centuries, silk making became simpler and more standardized. New inventions came quickly. The punched card loom appeared in 1775. This was later improved by Joseph-Marie Jacquard into the revolutionary Jacquard loom. This loom used punched cards to create complex designs automatically. These punched cards were an early form of computer programming. From 1801, embroidery-like designs could be mass-produced with this loom.

Workers initially protested the Jacquard loom, fearing it would cause unemployment. But it quickly became essential. In 1806, the loom was declared public property. Jacquard received a pension and royalties for each machine. By 1834, Lyon alone had 2,885 Jacquard looms. The Canut revolt in 1831, where silk workers occupied Lyon, showed the early struggles of workers during the Industrial Revolution.

Decline of European Silk

In 1845, silkworm diseases began to appear, causing a big epidemic. Diseases like pébrine, grasserie, and flacherie spread. These diseases also affected the mulberry trees. The chemist Jean-Baptiste Dumas asked Louis Pasteur to study the problem in 1865. Pasteur's work helped control the diseases.

However, the price of silkworm cocoons went up. Also, silk became less important in the clothes of the middle class in the 19th century. This led to the decline of the European silk industry. The opening of the Suez Canal in 1869 made it cheaper to import Asian silk.

By the late 19th century, Lyon's silk production was fully industrialized. Handlooms were disappearing. Advances in chemistry also affected the textile industry. New synthetic dyes were invented. In 1884, Hilaire de Chardonnet invented viscose, an artificial silk. This cheaper material partly replaced natural silk.

Silk Today

After the crisis in Europe, Japan became the world's top silk producer. By the early 20th century, Japan made 60% of the world's raw silk. Italy recovered from the crisis, but France did not. Many European farm workers left silk growing for factory jobs. Raw silk was imported from Japan to meet demand. Asian countries, which used to export raw materials, started exporting more finished silk clothes.

During World War II, silk supplies from Japan were cut off. Western countries had to find other materials. Synthetic fibers like nylon were used for things like parachutes and stockings. Even after the war, silk didn't get back many of its old markets. It remained an expensive luxury item.

Post-war Japan became the top exporter of raw silk until the 1970s. But the rise of synthetic fibers and changes in trade policy led to Japan's silk industry decline. By 1975, Japan was no longer a major silk exporter.

Today, China is the world's largest silk producer. In 1996, China produced 58,000 tonnes of silk out of a world total of 81,000. India was second with 13,000 tonnes. Japan's production is now very small.

In 2006, the United Nations declared 2009 the International Year of Natural Fibres. This was to highlight silk and other natural fibers.

Images for kids

-

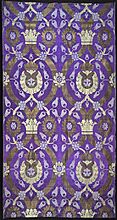

French silk brocade - Lyon 1760–1770

See also

In Spanish: Historia de la seda para niños

In Spanish: Historia de la seda para niños

| Kyle Baker |

| Joseph Yoakum |

| Laura Wheeler Waring |

| Henry Ossawa Tanner |