Rust facts for kids

Rust is a common type of corrosion. It happens when iron and things made of iron (like alloys such as steel) are left out in the air or water for a long time. Rust slowly breaks down iron into new substances. This happens because of a chemical reaction with oxygen in the air. Both air and water are needed for rust to form.

Almost all metals can corrode. But they can be protected. You can cover them with paint, oil, grease, or even plastic. Special methods like galvanizing or cathodic protection also work. Alloys like stainless steel rust much slower than pure iron. When iron rusts, it turns red or brown. The metal eventually gets weaker and falls apart.

Rust appears on metal if it is left outside in damp air. For example, rust often starts in small cracks in metals. Rain water can get into these cracks and stay there. This causes the metal to corrode and eventually turn into rust. Iron that has rusted is not strong anymore.

Some metals, like aluminium, titanium, and stainless steel, form a very thin, tough layer of corrosion on their surface. This layer protects the rest of the metal. It stops more oxygen from getting in. This is why aluminium stays shiny. It also makes aluminium seem like it doesn't react much, even though it can react with water. When iron rusts, it forms iron oxides that are not tough. This means air and water can keep getting in, and the iron keeps rusting.

Contents

What is Rust?

Rust is a general name for a mix of iron oxides and hydroxides. These form when iron or iron-containing alloys are exposed to oxygen and moisture for a long time. Over time, oxygen combines with the metal. This creates new substances called rust.

The word "oxidation" is much broader. It describes many processes where a substance loses electrons. Rusting is a specific type of oxidation that only happens to iron. Only iron or alloys that contain iron can rust. However, other metals can corrode in similar ways.

Water is the main thing that helps rust form. Iron or steel structures might look solid. But tiny water molecules can get into small holes and cracks in the metal. The hydrogen atoms in water can combine with other elements to form acids. These acids can expose even more metal. If chloride is present, like in saltwater, the corrosion happens much faster. Meanwhile, oxygen atoms combine with metal atoms. This forms the damaging rust compound. As these atoms combine, they weaken the metal. This makes the structure brittle and crumbly.

How Iron Rusts

When iron touches water and oxygen, it rusts. Some metals, like aluminium, form a protective layer of oxide. This layer stops more oxidation. But with iron, the protective layer of iron oxide changes into rust. This happens because of oxygen and water working together.

Other things that can make iron rust faster are sulfur dioxide and carbon dioxide in water. In these conditions, iron hydroxide forms. Unlike the protective iron oxides, these hydroxides do not stick to the metal. As they form and flake off, fresh iron is exposed. The rusting process continues until all the iron is gone. Or until all the oxygen, water, carbon dioxide, or sulfur dioxide is used up.

The rusting of iron is an electrochemical process. It starts with electrons moving from iron to oxygen. Iron gives up electrons, and oxygen gains them. Water speeds up this process. Things like salt (electrolytes) make it even faster. This is why road salt causes cars to rust quickly.

Stopping Rust

Stopping or slowing down rust is very important. Iron and steel products are used everywhere. Rust can pass through air and water. This means the iron under a rust layer will keep rusting. So, preventing rust means using coatings that stop rust from forming in the first place.

Rust-Resistant Metals

Stainless steel forms a protective layer of chromium(III) oxide. This layer stops the steel from rusting. Other metals like magnesium, titanium, zinc, and aluminium also form similar protective layers.

Special steel alloys, like "weathering steel" (Cor-Ten), rust much slower than normal steel. This is because the rust that forms on them sticks to the surface. It creates a protective layer. Even with this protection, these materials still rust slowly. So, designs using them must avoid the worst conditions.

Galvanizing

Galvanization is when a layer of zinc metal is put on an object. This can be done by dipping it in hot zinc or by electroplating. Zinc is used because it's cheap and sticks well to steel. It also protects the steel even if the zinc layer gets damaged. This is called cathodic protection. In places with more corrosion, like saltwater, cadmium plating is sometimes used instead.

Galvanization can sometimes fail at seams or holes. But even then, the zinc still protects the iron. It acts as a sacrificial anode. This means the zinc corrodes instead of the iron. But because the zinc layer gets used up, galvanization only protects for a limited time.

Newer coatings add aluminium to the zinc. These "zinc-alume" coatings are better. Aluminium can move to cover scratches. This provides protection for a longer time. These methods rely on the aluminium and zinc oxides to protect a scratched surface. They don't just act as a sacrificial anode. Sometimes, for very harsh environments or long-lasting protection, both zinc and another coating are used.

Cathodic Protection

Cathodic protection is a way to stop corrosion on buried or underwater structures. It works by giving the structure an electrical charge. This stops the chemical reaction that causes rust. If done correctly, corrosion can be stopped completely.

The simplest way to do this is by attaching a sacrificial anode. This makes the iron or steel the cathode. The sacrificial anode must be made of a metal that corrodes more easily than iron or steel. Common choices are zinc, aluminium, or magnesium. The sacrificial anode will eventually corrode away. So, it needs to be replaced on time to keep protecting the structure.

Cathodic protection can also use an electric current from an outside source. This is called Impressed Current Cathodic Protection (ICCP).

Coatings and Paint

Rust can be controlled with coatings like paint, lacquer, varnish, or wax. These coatings separate the iron from the air and water. Large structures, like ships and modern cars, often have a wax-based product injected into their hidden parts. These treatments usually also contain chemicals that stop rust.

Covering steel with concrete can also protect it. This is because the area where the steel meets the concrete is alkaline. However, steel in concrete can still rust. When rust expands, it can crack the concrete from the inside. This is a common problem for reinforced concrete bridges and buildings.

For example, iron clamps were used to join marble blocks when the Parthenon in Athens, Greece, was repaired in 1898. But the unprotected iron rusted and swelled. This caused a lot of damage to the marble. The ancient Greek builders had used a similar system. But they poured melted lead over the iron joints. This protected them from earthquakes and corrosion. Their method worked for 2500 years. But the newer, crude repairs were in danger of collapsing in less than a century.

Special anti-seize lubricants are available. They are put on metal threads and other precise metal parts to protect them from rust. These usually contain grease mixed with copper, zinc, or aluminium powder.

Bluing

Bluing is a method that gives limited rust protection to small steel items, like firearms. For it to work well, a water-displacing oil is rubbed onto the blued steel.

Inhibitors

Corrosion inhibitors can be used to stop rust inside sealed systems. These are chemicals that prevent corrosion. They don't work well if air can circulate. This is because fresh oxygen and moisture would keep coming in.

Humidity Control

Rust can be avoided by controlling the moisture in the air. For example, silica gel packets are used to control humidity in equipment shipped by sea.

Rust Removal

Rust can be removed from small iron or steel objects using electrolysis at home. You can use a plastic bucket with washing soda dissolved in tap water. A piece of rebar can be the anode (positive). Another piece of rebar can hold the object (cathode, negative). A battery charger provides the power.

Rust can also be treated with special products called rust converters. These contain tannic acid or phosphoric acid that react with the rust. Rust can also be removed with acids like citric acid and vinegar, or stronger ones like hydrochloric acid. Some commercial products use chelation agents, or even a solution of molasses.

Why Rust Matters

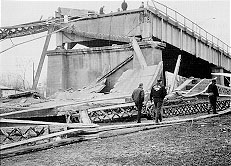

Rust causes tools and structures made of iron to break down. Rust takes up much more space than the original iron. So, when it builds up, it can push apart nearby parts. This is sometimes called "rust packing." It caused the collapse of the Mianus River Bridge in 1983. The internal bearings rusted and pushed one corner of the road slab off its support.

Rust was a big reason for the Silver Bridge disaster in 1967 in West Virginia. A steel suspension bridge collapsed in less than a minute. This killed 46 people. The Kinzua Bridge in Pennsylvania was blown down by a tornado in 2003. This happened mostly because the main bolts holding the structure to the ground had rusted away. The bridge was only held by gravity.

Reinforced concrete can also be damaged by rust. Steel and iron inside concrete can rust and expand. This internal pressure can cause the concrete to spall (break off in pieces). This creates serious structural problems. It is one of the most common reasons why reinforced concrete bridges and buildings fail.

- Structural failures caused by rust

-

The collapsed Silver Bridge, seen from the Ohio side.

-

The Kinzua Bridge after it collapsed.

-

Rusting rebar has expanded and broken off concrete from this reinforced concrete support.

Interesting Facts About Rust

- Some types of fungi can look like rust. They have similar color and texture and sometimes grow on metals.

- If salt is present, like in seawater or salt spray, iron tends to rust much faster.

- Typical galvanization of steel products uses a hot-dipped 85 µm zinc coating. In normal weather, this layer wears away at about 1 µm per year. This means it can protect the steel for about 85 years.

- When only temporary protection is needed for storage or transport, a thin layer of oil, grease, or a special mixture like Cosmoline can be put on an iron surface. This is often done when "mothballing" a steel ship, car, or other equipment for long-term storage.

- Rust is often used as a metaphor for slow decay that happens because of neglect.

- A large area of the American Midwest and American Northeast is called the "Rust Belt". This is because of tough economic problems that have affected the region.

Related pages

See also

In Spanish: Herrumbre para niños

In Spanish: Herrumbre para niños