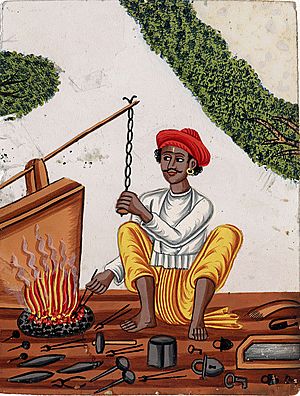

Blacksmith facts for kids

A blacksmith is a skilled person who shapes iron and steel. They use a hammer to hit hot metal on an anvil, changing its shape. Blacksmiths create many useful tools and other items from these metals.

A smith is someone who works with metal. A blacksmith works with iron and steel. Iron often looks dark or black, especially when it's heated in a blacksmith's fire. This is why the word "black" is part of "blacksmith."

A farrier is a special kind of blacksmith. They mainly work with iron to make horseshoes for horses.

Contents

The History of Blacksmiths

The first blacksmiths were the Hittites, an ancient group of people. They began shaping iron to make tools around 1500 BC. For a very long time, the ways blacksmiths made tools stayed pretty much the same.

Around the 1850s, countries like the United States and the United Kingdom developed new ways to make steel and tools. Large factories started making tools much faster and cheaper than blacksmiths could. Because of this, there are now fewer blacksmiths in countries with many factories.

Today, many blacksmiths create beautiful iron art. They make things like fancy gates, stair railings, and outdoor furniture. People buy these items because each piece is unique and handmade.

The Blacksmith's Forge

To shape iron, it must be very hot. Hot iron cools down quickly, so a blacksmith only has a few seconds to hammer it before it needs to go back into the fire.

A blacksmith uses a special fire called a forge. This forge burns coal or charcoal to create very high temperatures. A bellows is used to push air into the fire, making it burn even hotter. The blacksmith places pieces of iron into this hot fire to get them ready for shaping.

How Blacksmiths Shape Iron

Blacksmiths use different hammering methods to change the shape of hot iron. Here are some important ways:

- Bending: This means hammering a hot piece of iron to make it curve or create a sharp corner.

- Drawing: When a blacksmith hammers the sides of hot iron, it becomes longer and thinner.

- Upsetting: This involves hammering the end of a hot iron piece to make it shorter and thicker.

A punch is a tool that looks like a short iron stick with a flat end.

- Punching: A blacksmith hammers a punch through hot iron to make a hole.

A chisel is another tool, like a short iron stick with a sharp cutting end.

- Cutting: A blacksmith hammers a chisel through the side of a hot iron piece to cut it into two shorter pieces.

- Splitting: This is when a blacksmith hammers a chisel into the end of a hot iron stick. This makes the stick split into a "Y" shape, like a fork.

- Riveting: A rivet is like a metal pin with a head on both ends. Rivets are used to join different pieces of iron together. The blacksmith makes a hole in each piece, puts the rivet through, and then hammers the rivet to create a second head, holding the pieces tightly.

- Welding: This is the process of joining different pieces of iron to make them one solid piece. The blacksmith heats the iron pieces until they are almost melting. Then, they press them together and hammer them so that no seam is visible. Welding is one of the hardest skills for a blacksmith to master.

Working with Hard Iron and Steel

Iron is a natural chemical element. Steel is mostly iron, but it has a small amount of carbon mixed in (about 0.3% to 1.7% carbon by weight).

All metals become harder when a smith hammers or bends them. This is called "work-hardening." If a smith keeps hammering metal that is already work-hardened, it can crack and break. To make work-hardened metal soft again, so it can be shaped more, the smith "anneals" it.

To anneal iron or steel, a blacksmith heats the metal until it no longer attracts a magnet. Then, they let the metal cool down very slowly. Blacksmiths might cover the hot metal with sand so it takes hours to cool. This process makes the iron or steel very soft.

Steel behaves like iron until a blacksmith "heat-treats" it. Heat-treating is a special way to heat and cool steel so it becomes hard enough to keep a sharp blade edge. A blade made from plain iron would quickly become dull. Good blades for knives, chisels, axes, and other cutting tools are always made of steel, then heat-treated, and finally sharpened.

To heat-treat steel, a blacksmith heats it until it no longer attracts a magnet. Then, they cool the steel very quickly. This is called "quenching." A blacksmith might put the hot steel into a bucket of water and move it around until it's cold. After quenching, the steel will be as hard as possible. It can even be so hard that it might break like glass if hit or dropped.

The next step is to "temper" the steel. This makes it less brittle so it won't break like glass. To temper steel, a blacksmith polishes a part of the steel to make it smooth and shiny. Then, they slowly heat the steel in the fire. As the steel heats up, the polished surface will change colors. These colors don't glow; they look like a stain on the steel. As the steel gets hotter, it will turn yellow, then brown, then purple, and finally blue. Yellow means the steel will still be very hard, while blue means it will be a bit softer (but still hard). When the steel reaches the desired color, the blacksmith puts it into water to stop the color change. Different tools are tempered to different colors, depending on their use and the type of steel. For example, stone chisels might be tempered to yellow, and axes for cutting trees might be tempered to blue.

A blacksmith does not hammer a blade edge to be very thin. Instead, they hammer the steel so the edge stays thick. After the heat-treating and tempering process, stones are used to grind the blade edge to make it sharp.

If a blacksmith has a piece of metal but isn't sure if it's iron or steel, they can try to heat-treat it like steel. If it doesn't become hard, then it's iron. Iron will show the same temper colors as steel, but it won't become hard.

If a blacksmith has an old steel tool and wants to reshape it into a new tool, they first anneal the steel. This makes the steel very soft, like iron. Then, the blacksmith can hammer it into a new shape, and finally heat-treat and temper it to create a new, hard steel tool.

Blacksmiths must be careful when hammering hardened steel or work-hardened iron. Small pieces can break off and fly, which could hurt their eyes. Many blacksmiths wear plastic safety glasses to protect their eyes.

Things Blacksmiths Make

Blacksmiths have made many important items throughout history, including:

- Weapons

- Armor

- Helmets

- Shields

- Chain mail shirts

- Suits of plate armor

- Tools

- Hardware

Images for kids

-

Wayland's smithy in the centre, Níðuð's daughter Böðvildr to the left, and Níðuð's dead sons hidden to the right of the smithy. Between the girl and the smithy, Wayland can be seen in an eagle fetch flying away. From the Ardre image stone VIII on Gotland

-

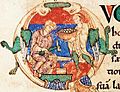

The artist William Blake used the blacksmith as a motif in his own extensive mythology. Here, Los, a protagonist in several of Blake's poems, is tormented at his smithy by the figure Spectre in an illustration Blake's poem Jerusalem. This image comes from Copy E. of that work, printed in 1821 and in the collection of the Yale Center for British Art

-

Ilmarinen Forges the Sampo, Berndt Godenhjelm, 19th century

-

A blacksmith shop in the harbor of Saint John, New Brunswick, Canada in the late 19th century

-

High school blacksmith class, Salt Lake City, Utah, 1915

-

Chancel iron gates designed by master blacksmith Samuel Yellin at Church of the Good Shepherd (Rosemont, Pennsylvania), USA

-

An Artist Blacksmith working with a power hammer in Bodom, Finland, 2011

-

Jesse Hoover blacksmith shop, Herbert Hoover National Historic Site

See also

In Spanish: Herrero para niños

In Spanish: Herrero para niños

| William L. Dawson |

| W. E. B. Du Bois |

| Harry Belafonte |