Ferrous metallurgy facts for kids

Ferrous metallurgy is all about how we work with iron and its special mixes, called alloys. These alloys include things like steel. Humans have been using iron for a very long time! The oldest iron objects we've found are from about 4,000 BC in Egypt. These first pieces of iron came from meteorites that fell to Earth.

We don't know exactly when or where people first learned to get iron from ore (rocks that contain metal). But by 2,000 BC, people in places like Greece and India were already making iron from these ores. Around 1,000 BC, people learned to make wrought iron, which is iron that has been shaped by hammering. This period is known as the Iron Age.

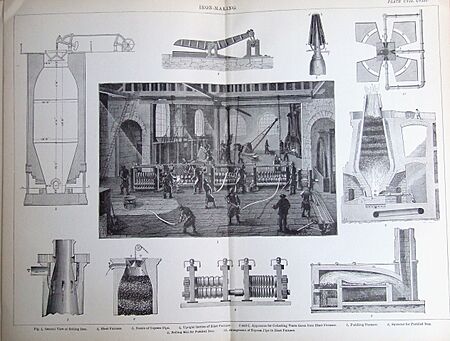

During the Middle Ages, skilled workers in Europe found a way to make wrought iron from cast iron, which was also called pig iron. They used special furnaces called finery forges. All these early ways of making iron needed charcoal as fuel.

By 400 BC, southern India was making a special type of steel called wootz steel. This steel was super strong and was traded all over the ancient world. Around 500 BC, people in China also started making cast iron. Later, in the 1600s, new ways to make steel were invented, like the cementation process.

During the Industrial Revolution, people found ways to use coke (a fuel made from coal) instead of charcoal to make iron and steel. This led to a huge increase in how much iron and steel could be made.

In the late 1850s, a man named Henry Bessemer invented a new way to make steel called the Bessemer process. This method blew air through melted pig iron to burn off carbon, making a strong, mild steel. Today, wrought iron isn't made much anymore because modern steel is so much better and easier to produce.

Contents

- Meteoric Iron: Iron from Space!

- Native Iron: Naturally Found Iron

- Iron Smelting and the Iron Age

- Medieval and Early Modern Europe: New Methods

- Transition to Coke in England: The Industrial Revolution

- Hot Blast: More Efficient Furnaces

- Industrial Steelmaking: Steel for Everyone

- Modern Steel Industry: A Global Giant

- See also

Meteoric Iron: Iron from Space!

Some of the very first iron used by humans came from meteorites that landed on Earth. These space rocks contain a special mix of iron–nickel alloys. We can often tell if ancient iron came from a meteorite because it has unique patterns inside, called Widmanstätten patterns. These patterns stay even when the metal is hammered when cold or slightly warm.

For example, a small iron bead from about 5,000 BC was found in Iran. Also, spear tips and decorations made from meteoric iron were found in ancient Egypt and Sumer from around 4,000 BC.

These early iron objects were mostly used for ceremonies or decoration. Meteoric iron was very rare and probably super expensive, maybe even more valuable than gold! The ancient Hittites even traded iron (whether from meteorites or smelted) for silver at a very high rate with Assyria around 2,000 BC.

People in the Arctic, like the Thule people in Greenland, also used meteoric iron. They made harpoons, knives, and other tools from pieces of the Cape York meteorite. They would hammer small bits of metal into flat disks and attach them to bone handles. These tools were even traded with other groups, with some found over 1,000 miles away! When explorer Robert Peary brought the largest piece of the Cape York meteorite to New York City in 1897, it still weighed over 33 tons!

Native Iron: Naturally Found Iron

Sometimes, iron can be found naturally in its metallic form, not just in meteorites. This is very rare and usually appears as tiny pieces inside certain rocks called basalt. Besides meteoric iron, the Thule people of Greenland also used this "native iron" from the Disko region.

Iron Smelting and the Iron Age

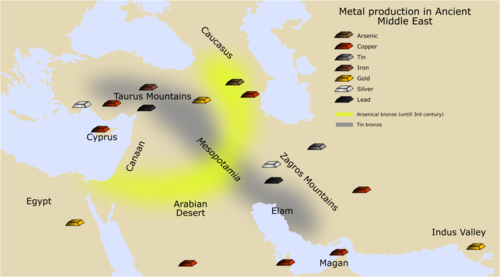

Smelting iron means getting usable metal from iron ores (rocks with iron in them). This is harder than smelting tin or copper. Tin and copper can be melted in simple furnaces and poured into molds. But smelted iron needs to be worked when hot and can only be melted in special, very hot furnaces. Iron is often found with copper ores, so it's not surprising that people learned to smelt iron only after thousands of years of working with bronze (a mix of copper and tin).

We don't know the exact time or place where iron smelting was discovered. It's hard to tell the difference between iron from nickel-containing ores and hot-worked meteoric iron. But archaeological clues suggest it might have started in the Middle East around 3,000 BC. However, objects made from wrought iron were still very rare until about 1,200 BC.

The Iron Age is known as the time when iron and steel weapons and tools widely replaced those made of bronze. This change happened at different times in different places as the technology spread. Mesopotamia entered the Iron Age by 900 BC. Even though Egypt made some iron, bronze was still more common until Assyria conquered them in 663 BC. India's Iron Age began around 1,200 BC, Central Europe's around 800 BC, and China's around 300 BC. Around 500 BC, the Nubians, who learned about iron from the Assyrians, became big producers and traders of iron.

Ancient Near East: Early Iron Making

One of the earliest iron objects made from smelting is a dagger with an iron blade found in a Hattic tomb in Anatolia, dating back to 2,500 BC. Around 1,500 BC, more smelted iron objects started appearing in Mesopotamia, Anatolia, and Egypt. For example, 19 iron objects were found in the tomb of Egyptian ruler Tutankhamun, who died in 1323 BC. These included an iron dagger with a gold handle and other tools.

Even though iron objects from the Bronze Age have been found across the Eastern Mediterranean, bronze was still much more common. As the iron technology spread, iron began to replace bronze as the main metal for tools and weapons in places like the Levant, Cyprus, Greece, Crete, Anatolia, and Egypt.

Iron was first smelted in furnaces called bloomeries. In these furnaces, workers used bellows to blow air through a pile of iron ore and burning charcoal. The charcoal created a gas called carbon monoxide, which changed the iron oxide in the ore into metallic iron. However, the bloomery wasn't hot enough to melt the iron completely. Instead, the metal gathered at the bottom as a spongy mass called a bloom. Workers then had to repeatedly beat and fold this bloom to squeeze out the melted waste material, called slag. This hard and long process made wrought iron, which was flexible but quite soft.

At the same time that iron became more common, people also discovered carburization. This is the process of adding carbon to wrought iron. While the iron bloom had some carbon, most of it was lost during the hot-working process. Smiths in the Middle East found that they could make wrought iron much harder by heating the finished piece in a bed of charcoal and then quickly cooling it in water or oil. This process turned the outer layers of the iron into steel, which is a mix of iron and iron carbides. The inside of the piece remained as less brittle iron.

How Iron Smelting Might Have Started

For a long time, people thought that the Hittites of Anatolia, from the Late Bronze Age, were the first to develop iron smelting. It was believed they kept this knowledge a secret, and that their empire became powerful because of it. According to this idea, when the ancient Sea Peoples invaded and destroyed the Hittite empire, they spread the knowledge of iron working across the region. However, this idea isn't widely accepted anymore because there's no strong proof that the Hittites had a monopoly on iron. The number of iron objects found from that time in Anatolia is similar to what's found in Egypt and other places, and only a few were weapons.

A newer idea suggests that iron technology grew because the trade routes for copper and tin were disrupted when empires collapsed at the end of the Late Bronze Age. These metals, especially tin, were not easy to find everywhere and had to be transported long distances. Iron ores, however, were much more common. But there's no clear archaeological evidence that there was a shortage of bronze or tin in the early Iron Age. Bronze objects were still plentiful, and they had the same amount of tin as those from the Late Bronze Age.

Indian Subcontinent: Advanced Steel

The history of working with iron in India began around 2,000 BC. Iron tools have been found in the Gangetic plains dating between 1,800 and 1,200 BC. By the early 1,200s BC, people in India were smelting iron on a large scale. In southern India, iron was used as early as 1,200 to 1,100 BC. Iron-making technology improved during the stable Maurya Empire period and other peaceful times in the 1,000s BC.

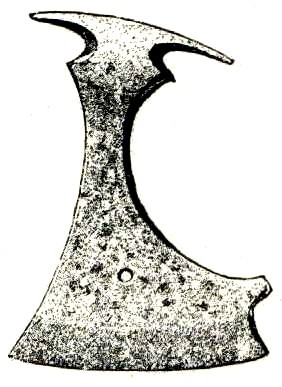

Iron objects like spikes, knives, daggers, arrow-heads, bowls, spoons, saucepans, axes, chisels, tongs, and door fittings, dating from 600 to 200 BC, have been found at many sites in India. The Greek historian Herodotus was the first Westerner to write about India's use of iron. Ancient Indian texts, like the Upanishads, also mention weaving, pottery, and metalworking. The Romans greatly admired the excellent steel from India during the time of the Gupta Empire.

Perhaps as early as 500 BC, and definitely by 200 AD, high-quality steel was made in southern India using the crucible technique. In this method, very pure wrought iron, charcoal, and glass were mixed in a crucible (a heat-resistant pot) and heated until the iron melted and absorbed carbon. Iron chains were even used in Indian suspension bridges as early as the 4th century AD.

Wootz steel was produced in India and Sri Lanka from around 300 BC. This steel was famous in ancient times for being very strong and holding a sharp edge. It's said that when King Porus asked Alexander the Great what gift he wanted, Alexander chose 30 pounds of steel over gold or silver! Wootz steel was a complex mix, mainly iron with tiny amounts of other elements. Recent studies suggest its amazing qualities might have come from tiny structures called carbon nanotubes forming in the metal. The technology for Wootz steel spread to the Persians and then to Arabs, who brought it across the Middle East. In the 16th century, the Dutch brought this technology from South India to Europe, where it was later mass-produced.

Steel was also made in Sri Lanka from 300 BC using furnaces powered by monsoon winds. These furnaces were built on hilltops, and long trenches directed the wind into air vents. This created a strong airflow that allowed for higher temperatures than furnaces with bellows, leading to better-quality iron. Steel from Sri Lanka was widely traded in the region and the Islamic world.

One of the world's most amazing metal objects is the iron pillar of Delhi in India. This pillar is made of wrought iron (98% iron), is almost seven meters tall, and weighs over six tons. It was put up by Chandragupta II Vikramaditya and has stood for 1,600 years in heavy rains with very little rust!

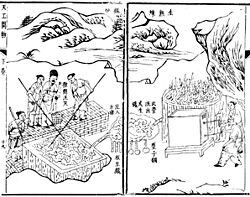

China: Mastering Cast Iron

Historians debate whether ironworking using bloomeries spread to China from the Middle East. One idea is that metalworking came through Central Asia. However, in 2008, two iron pieces found in Gansu, China, were dated to the 14th century BC. One of these was made from bloomery iron, not meteoric iron, suggesting that China might have developed ironworking on its own.

The earliest iron objects made from bloomeries in China date to the late 9th century BC. Cast iron was used in ancient China for warfare, farming, and buildings. Around 500 BC, metalworkers in the southern state of Wu reached very high temperatures (1130 °C). At this temperature, iron mixes with 4.3% carbon and melts. This liquid iron could then be poured into molds, which was much easier than hammering each piece of iron from a bloom.

Cast iron is quite brittle and not good for tools that need to strike things. But it can be made into steel or wrought iron by heating it in air for several days to remove carbon. In China, these ironworking methods spread north. By 300 BC, iron was the main material for most tools and weapons across China. A mass grave from the early 3rd century BC in Hebei province contained soldiers buried with weapons made of wrought iron, cast iron, and hardened steel.

During the Han Dynasty (202 BC–220 AD), the government made ironworking a state-controlled business. They built large blast furnaces in Henan province, each able to produce several tons of iron per day. By this time, Chinese metalworkers had figured out how to refine melted pig iron by stirring it in the open air until it lost its carbon and could be hammered (wrought). In modern Chinese, this process is called chao, which means "stir-frying." Pig iron was called "raw iron," and wrought iron was "cooked iron." By the 1st century BC, Chinese metalworkers discovered that mixing melted wrought iron and cast iron together could create steel, which has a medium carbon content.

Legend says that the sword of Liu Bang, the first Han emperor, was made this way. Some old texts mention "harmonizing the hard and the soft" when talking about ironworking, which might refer to this process. The ancient city of Wan (Nanyang) was a major center for the iron and steel industry during the Han period. Besides their own steel-making methods, the Chinese also adopted the methods for making Wootz steel, which came from India by the 5th century AD.

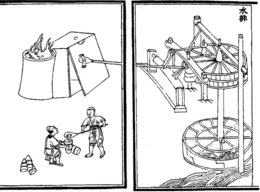

During the Han Dynasty, the Chinese were also the first to use hydraulic power (like a waterwheel) to operate the bellows of a blast furnace. This was recorded in 31 AD as an invention by the engineer Du Shi. The first drawing of this water-powered system appeared in a book called Nong Shu in 1313 AD.

In the 11th century, there's proof that Song China produced steel using two methods: one that made lower-quality steel and another that was similar to the modern Bessemer process, which involved repeatedly hammering iron under a cold blast to remove carbon. By the 11th century, there was a lot of deforestation in China because the iron industry needed so much charcoal. However, the Chinese then learned to use bituminous coke instead of charcoal, which saved many forests.

Iron Age Europe: Spreading the Knowledge

The earliest smelted iron object found in Europe is a knife blade from Ukraine, dating to about 2,500 BC. During most of the Middle and Late Bronze Age in Europe, iron was present but rare. It was used for jewelry, small knives, and repairs on bronze items. Early smelted iron finds in central Europe include an iron knife from Slovakia (possibly 18th century BC), an iron ring from Germany (around 15th century BC), and an iron chisel from Germany (around 1,000 BC).

Iron metallurgy began in Scandinavia during the later Nordic Bronze Age, from at least 900 BC. In the 11th century BC, iron swords replaced bronze swords in Southern Europe, especially in Greece. By the 10th century BC, iron became the most common metal. In the Pannonian Basin, there was a big increase in iron finds from the 10th century BC onwards. Iron swords have been found in central Europe dating from the 10th century BC, but the Iron Age truly began with the Hallstatt culture from 800 BC.

From 500 BC, the La Tène culture saw a big increase in iron production. Iron metallurgy also became common in southern Scandinavia. In northern Sweden, steel manufacturing dates back to around 0 AD. The spread of ironworking in Central and Western Europe is linked to the expansion of the Celts. Celtic smiths made steel from about 800 BC for swords, and high-carbon steel production is confirmed in Britain after about 490 BC. By the 1st century BC, Noric steel was famous for its quality and was sought after by the Roman military.

The Roman Empire is estimated to have produced about 84,750 tons of iron each year.

Sub-Saharan Africa: Independent Innovations

Scientific knowledge and technological development in metalworking started in many places across Africa, including West, Central, and East Africa. This means these metalworking methods were developed by native African people. Iron metallurgy developed in Nigeria between 2631 BC and 2458 BC, in the Central African Republic between 2136 BC and 1921 BC, in Niger between 1895 BC and 1370 BC, and in Togo between 1297 BC and 1051 BC.

Although there's some debate, some archaeologists believe that iron metallurgy developed independently in sub-Saharan Africa (possibly in West Africa). People in Termit, eastern Niger, were smelting iron around 1,500 BC. In the Aïr Mountains in Niger, there are also signs of independent copper smelting between 2,500 and 1,500 BC.

Archaeological sites with iron smelting furnaces and slag (waste material) have been found in the Nsukka region of southeast Nigeria (in what is now Igboland). These sites date to 2,000 BC at Lejja and 750 BC at Opi. The site of Gbabiri in the Central African Republic shows evidence of iron metallurgy from a furnace and blacksmith workshop, with dates as early as 896–773 BC. Similarly, bloomery-type furnaces appear in the Nok culture of central Nigeria by about 550 BC, and possibly even earlier.

There is also evidence that carbon steel was made in Western Tanzania by the ancestors of the Haya people as early as 2,300 to 2,000 years ago (around 300 BC or soon after). They used a complex "pre-heating" process that allowed temperatures inside their furnaces to reach 1300 to 1400 °C.

Iron and copper working spread southward across Africa, reaching the Cape around 200 AD. The widespread use of iron changed the Bantu-speaking farming communities who adopted it. They became wealthy and powerful, producing iron for tools and weapons in large amounts.

The earliest records of bloomery-type furnaces in East Africa are discoveries of smelted iron and carbon in Nubia that date back to between the 7th and 6th centuries BC. Especially in Meroe, there were ancient bloomeries that made metal tools for the Nubians and Kushites, and even produced extra for their economy.

Medieval Islamic World: Innovations in Steel

Iron technology was further improved by several inventions in medieval Islam during the Islamic Golden Age. By the 11th century, every region in the Muslim world had these industrial mills working, from Islamic Spain in the west to the Middle East and Central Asia in the east. There are also mentions of cast iron from the 10th century, and archaeological proof of blast furnaces being used in the Ayyubid and Mamluk empires from the 11th century. This suggests that Chinese metal technology spread to the Islamic world.

One of the most famous steels made in the medieval Near East was Damascus steel, used for swordmaking. It was mostly produced in Damascus, Syria, from 900 to 1750 AD. This steel was made using the crucible steel method, based on the earlier Indian wootz steel. The exact process is still a bit of a mystery, but it allowed tiny hard particles called carbides to form in layers within the blade. Carbides are much harder than the surrounding softer steel, so swordsmiths could make an edge that cut hard materials, while the softer steel bands kept the sword strong and flexible. Researchers using X-rays and electron microscopes to study Damascus steel found tiny cementite nanowires and carbon nanotubes. These tiny structures are thought to give Damascus steel its special properties and are a result of the forging process.

Medieval and Early Modern Europe: New Methods

For many centuries, there wasn't a huge change in how iron was made in Europe. European metalworkers kept using bloomeries. However, the Medieval period brought two important developments: using water power in the bloomery process and the first production of cast iron in Europe.

Powered Bloomeries: Water Power for Iron

At some point in the medieval period, water power was used to help the bloomery process. This might have happened at the Cistercian Abbey of Clairvaux as early as 1135. But it was definitely used in France and Sweden by the early 13th century. In England, the first clear record of this is from a forge near Bedburn in 1408. Powered bloomeries were used in some parts of England until the early 1700s.

The Catalan Forge was another type of powered bloomery. Bloomeries that used hot blast (preheated air) were even used in upstate New York in the mid-1800s.

Blast Furnace: Melting Iron

The blast furnace became the main way to produce iron in Europe until the puddling process was developed in 1783–84. Cast iron production was slower to develop in Europe because people mostly wanted wrought iron. Making cast iron first required an expensive blast furnace and then more refining to turn it into wrought iron, which took a lot of work and money.

For much of the Middle Ages in Western Europe, iron was still made by working iron blooms into wrought iron. Some of the earliest iron casting in Europe happened in Sweden, at two sites, Lapphyttan and Vinarhyttan, between 1150 and 1350. Some experts think this practice might have come from the Mongols across Russia, but there's no clear proof. By the late 1300s, there was a growing demand for cast iron goods, especially for cannonballs.

Finery Forge: Refining Pig Iron

Another way to remove carbon from pig iron was the finery forge. This method seems to have been invented around Namur in the 1400s. By the end of that century, this method, called the Walloon process, spread to England. It became the main way to make wrought iron by 1600. It was brought to Sweden in the early 1600s and was used to make oregrounds iron, which was favored by English steelmakers.

A different version of this was the German forge. This became the main way to produce bar iron in Sweden.

Cementation Process: Making Blister Steel

In the early 1600s, ironworkers in Western Europe developed the cementation process to add carbon to wrought iron. Wrought iron bars and charcoal were packed into stone boxes, sealed with clay, and then heated to a red hot temperature for up to a week in an oxygen-free environment surrounded by almost pure carbon (charcoal). During this time, carbon soaked into the surface layers of the iron, creating cement steel or blister steel. This process made the parts of the iron that were in contact with carbon much harder, like the blade of an axe. The earliest place this process was used in England was at Coalbrookdale from 1619. The quality of the steel could be improved by a process called faggoting, which produced shear steel.

Crucible Steel: More Consistent Steel

In the 1740s, Benjamin Huntsman found a way to melt blister steel (made by the cementation process) in special pots called crucibles. The crucible steel that resulted, usually cast into solid blocks called ingots, was much more consistent and uniform than blister steel.

Transition to Coke in England: The Industrial Revolution

Beginnings: Finding New Fuel

Early iron smelting used charcoal as both the heat source and the material that removed oxygen from the iron ore. By the 1700s, there wasn't enough wood to make charcoal, which limited how much iron could be produced. So, England relied heavily on Sweden and later Russia for much of its iron.

Smelting iron with coal (or its product, coke) was a goal for a long time. Dud Dudley probably managed to produce pig iron with coke around 1619. Shadrach Fox might have smelted iron with coke at Coalbrookdale in the 1690s, but only for cast iron products like cannonballs.

Abraham Darby and His Successors: Coke Takes Over

In 1707, Abraham Darby I patented a way to make cast iron pots. His pots were thinner and cheaper than others. To get more pig iron, he rented a blast furnace at Coalbrookdale in 1709. There, he successfully made iron using coke, starting the first successful business in Europe to do so. His products were all cast iron, though his immediate family members tried to refine this into bar iron with little success.

Bar iron continued to be made with charcoal pig iron until the mid-1750s. In 1755, Abraham Darby II opened a new coke-using furnace at Horsehay in Shropshire. These furnaces supplied coke pig iron to traditional finery forges to make bar iron. The reason for this delay in switching to coke for bar iron production is still debated.

New Forge Processes: Making Bar Iron Easier

It was only after this that cheaper ways to turn pig iron into bar iron were invented. A process called potting and stamping was developed in the 1760s and improved in the 1770s. It became widely used in the West Midlands from about 1785. However, this was mostly replaced by Henry Cort's puddling process, patented in 1784. These processes allowed for the huge increase in iron production that was a key part of the Industrial Revolution for the iron industry.

In the early 1800s, Hall discovered that adding iron oxide to the puddling furnace caused a strong reaction that removed carbon from the pig iron. This became known as 'wet puddling'. It was also found that steel could be made by stopping the puddling process before all the carbon was removed.

Hot Blast: More Efficient Furnaces

The blast furnace became even more efficient with the change to hot blast, patented by James Beaumont Neilson in Scotland in 1828. This greatly reduced production costs. Within a few decades, furnaces had a large 'stove' next to them. Waste gas from the furnace (containing carbon monoxide) was sent into this stove and burned. The heat from this burning gas was used to preheat the air blown into the furnace.

Industrial Steelmaking: Steel for Everyone

Apart from some puddled steel production, English steel continued to be made by the cementation process, sometimes followed by remelting to produce crucible steel. These were batch processes that used bar iron, especially Swedish oregrounds iron, as their raw material.

The problem of making cheap steel in large amounts was solved in 1855 by Henry Bessemer. He introduced the Bessemer converter at his steelworks in Sheffield, England. (You can still see an early converter at the city's Kelham Island Museum.) In the Bessemer process, melted pig iron from the blast furnace was put into a large container. Then, air was blown through the melted iron from below, which ignited the carbon dissolved in the iron. As the carbon burned off, the melting point of the mixture increased, but the heat from the burning carbon kept the mixture melted. Once the carbon content dropped to the right level, the air was cut off. A typical Bessemer converter could turn a 25-ton batch of pig iron into steel in just half an hour!

In the 1860s, new furnaces called regenerative furnaces and better heat-resistant linings allowed steel to be melted in an open hearth. This process was slow and used a lot of energy, but it allowed for better control over the steel's chemical makeup and let people recycle iron scrap.

The acidic lining of early Bessemer converters and open hearths couldn't remove phosphorus from steel using lime. This meant that puddling furnaces were still used to process phosphorus-rich iron ores common in Europe. However, in the 1870s, the Gilchrist–Thomas process was developed, and later, basic linings were also used for open hearths.

Finally, the basic oxygen process was introduced in 1952. This was a change to the basic Bessemer process. It blows oxygen from above the steel (instead of bubbling air from below), which reduces how much nitrogen gets into the steel. The basic oxygen process is used in all modern steelworks today. The last Bessemer converter in the U.S. was retired in 1968. Also, in the last 30 years, there's been a huge increase in "mini-mills," where only scrap steel is melted using an electric arc furnace. These mills first only made bar products, but now they also make flat and heavy products, which used to be made only by large, integrated steelworks.

Before these developments in the 1800s, steel was very expensive and only used for a few things where a super hard or flexible metal was needed, like for tool edges and springs. The wide availability of cheap steel powered the Second Industrial Revolution and led to modern society as we know it. Mild steel eventually replaced wrought iron for almost everything, and wrought iron is no longer made commercially. With a few small exceptions, alloy steels (steels mixed with other metals) only started to be made in the late 1800s. Stainless steel was developed just before World War I and wasn't widely used until the 1920s.

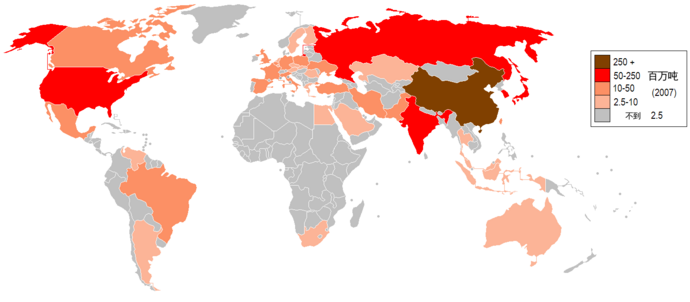

Modern Steel Industry: A Global Giant

The steel industry is often seen as a sign of how well an economy is doing. This is because steel is so important for building infrastructure and for overall economic development. In 1980, there were over 500,000 steelworkers in the U.S. By 2000, that number had fallen to 224,000.

The economic boom in China and India caused a massive increase in the demand for steel. Between 2000 and 2005, worldwide steel demand grew by 6%. Since 2000, several Indian and Chinese steel companies have become very important, such as Tata Steel (which bought Corus Group in 2007), Baosteel Group, and Shagang Group. 2017, ArcelorMittal is the world's largest steel producer. In 2005, the British Geological Survey reported that China was the top steel producer, making about one-third of the world's steel. Japan, Russia, and the U.S. followed.

Making a lot of steel creates a significant amount of carbon dioxide emissions, especially with the main production methods. In 2019, it was estimated that 7% to 9% of global carbon dioxide emissions came from the steel industry. To reduce these emissions, changes are expected, such as shifting from coke-based production, recycling more steel, and using technologies to capture and store or use carbon.

In 2008, steel began to be traded like other goods on the London Metal Exchange. However, at the end of 2008, the steel industry faced a sharp downturn, leading to many cutbacks.

See also

- Bintie, a type of refined iron

- History of steelmaking

- Iron Age

- List of alloys

- Nok culture

- Non-ferrous extractive metallurgy

- Roman metallurgy

| Frances Mary Albrier |

| Whitney Young |

| Muhammad Ali |